AC-SVX001A-EN

33

• Shutoff (isolation) valves.

• Thermometers.

• Clean-out tees.

• Balancing valve.

Drains

A 1/2” drain connection is located under outlet end of

evaporator waterbox for drainage during unit

servicing. A shutoff valve must be installed on drain

line.

Pressure Gauges

Install field-supplied pressure components as shown in

figure above. Locate pressure gauges or taps in a

straight run of pipe; avoid placement near elbows, etc.

Be sure to install the gauges at the same elevation on

each shell if the shells have opposite-end water

connections.

To read manifolded pressure gauges, open one valve

and close the other (depending upon the reading

desired). This eliminates errors resulting from

differently calibrated gauges installed at unmatched

elevations.

Pressure Relief Valves

NNOOTTIICCEE

EEvvaappoorraattoorr DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd ccaauussee

ddaammaaggee ttoo tthhee eevvaappoorraattoorr..

TToo pprreevveenntt eevvaappoorraattoorr ddaammaaggee,, iinnssttaallll pprreessssuurree

rreelliieeff vvaallvveess iinn tthhee eevvaappoorraattoorr wwaatteerr ssyysstteemm..

Install a water pressure relief valve in the evaporator

inlet piping between the evaporator and the inlet

shutoff valve, as shown in figure above. Water vessels

with close-coupled shutoff valves have a high potential

for hydrostatic pressure buildup on a water

temperature increase. Refer to applicable codes for

relief valve installation guidelines.

Evaporator Flow Switch

NNOOTTIICCEE

FFllooww SSwwiittcchh DDaammaaggee!!

IInnccoorrrreecctt vvoollttaaggee aapppplliiccaattiioonn ccoouulldd ccaauussee ddaammaaggee

ttoo tthhee ffllooww sswwiittcchh..

FFllooww sswwiittcchh iiss oonn aa 2244VV cciirrccuuiitt.. DDoo NNOOTT aappppllyy 112200VV

ttoo tthhee ffllooww sswwiittcchh..

The flow switch is factory-installed and programmed

based on the operating conditions submitted with the

order. The leaving evaporator temperature, fluid type

and fluid concentration affect the selected flow switch.

If the operating conditions on the job site change, the

flow switch may need to be replaced. Contact your

local Trane Sales office for more information.

The sensor head includes 3 LEDs, two yellow and one

green. Wait 15 seconds after power is applied to the

sensor before evaluating LEDs for flow status. When

wired correctly and flow is established, only the green

LED should be lit. Following are the LED indicators:

• Green ON, both yellow OFF — Flow

• Green and outside yellow ON — No Flow

• Center yellow ON continuously — Miswire

Factory installed jumper wire W11 must be removed if

using auxiliary contacts and/or additional proof of flow.

See schematics in AC-SVE001*-EN for more details.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

IInnccoorrrreecctt wwiirriinngg ooff aauuxxiilliiaarryy ccoonnttaaccttss ccoouulldd ccaauussee

eeqquuiippmmeenntt ddaammaaggee..

SSeeee sscchheemmaattiiccss ffoorr pprrooppeerr wwiirriinngg..

If using auxiliary flow sensing, both yellow LEDs come

on initially when flow is stopped. The center yellow

LED will turn off after approximately 7 seconds. The

LED indicators are otherwise the same as indicated

above.

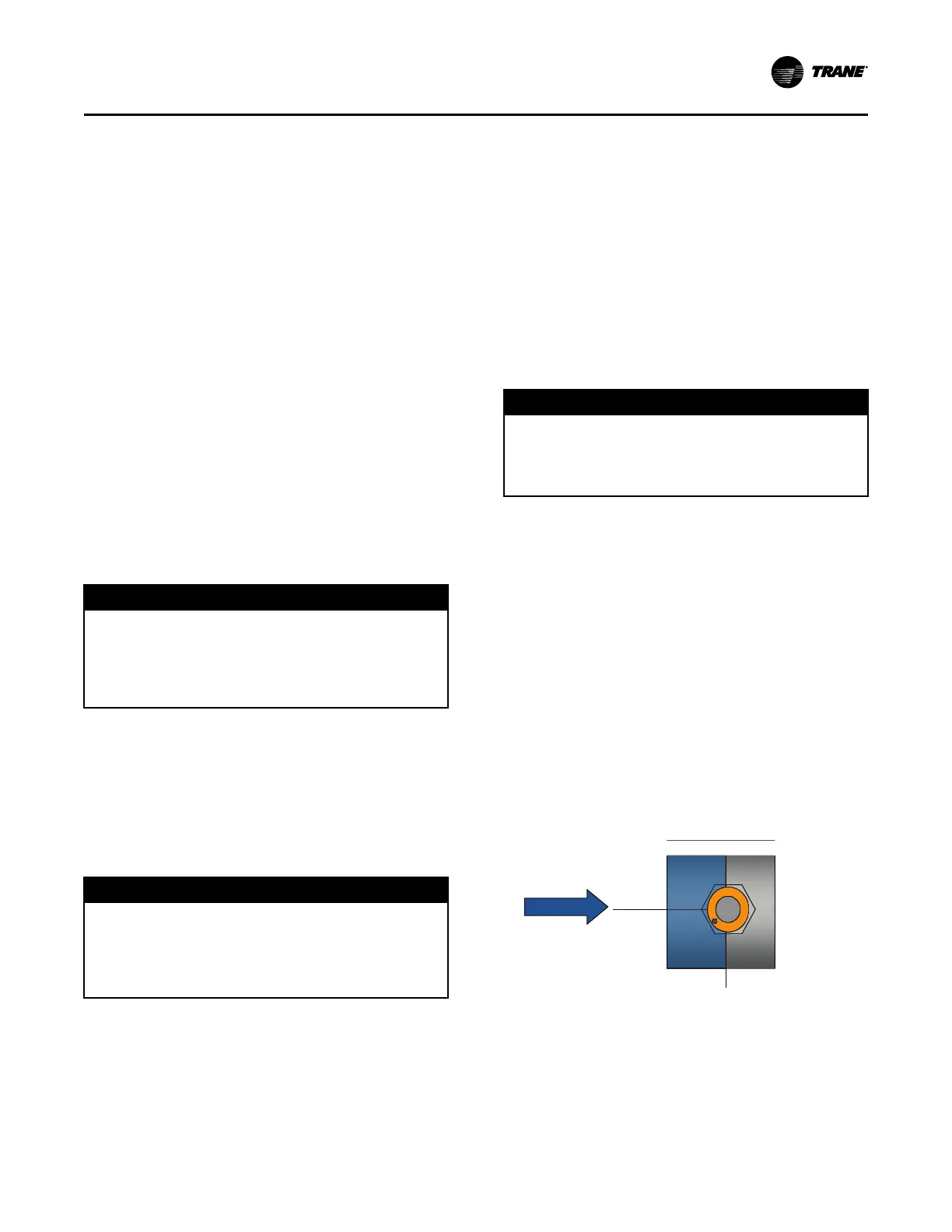

Indexing Flow Switch

To properly index the flow switch, the following

requirements must be met:

• The dot must be at a position no greater than 90° off

Index.

• The torque must be between 22 ft-lb minimum and

74 ft-lb maximum.

• A minimum distance of 5x pipe diameter must be

maintained between flow switch and any bends,

valves, changes in cross sections, etc.

Figure 16. Proper flow switch indexing

Loading...

Loading...