42

AC-SVX001A-EN

LLIDs. Service power connection allows for a NEMA 5-

15 style extension cord to power on Class 2 devices (i.e.

UC800, LLIDs, EXVs, and TD7 display) with an external

power source, without the need of line voltage applied

to the unit. This connection is to be made at 1XJ50. The

extension cord power source is required to have

upstream current protection rated at no more than 10A.

The required voltage for the service power connection

is 115V at 60Hz and 110V at 50Hz.

Heater Power Supply

The evaporator shell is insulated from ambient air and

protected from freezing temperatures by

thermostatically-controlled immersion heaters. See

table below for evaporator heater summary. Whenever

the water temperature drops to approximately 37°F

(2.8°C), the thermostat energizes the heaters. The

heaters will provide protection from ambient

temperatures down to -20°F (-29°C).

NNOOTTIICCEE

EEvvaappoorraattoorr DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

eevvaappoorraattoorr ddaammaaggee..

AA qquuaalliiffiieedd tteecchhnniicciiaann mmuusstt ccoonnffiirrmm ooppeerraattiioonn ooff

tthhee tthheerrmmoossttaatt.. CCoonnttrrooll ppaanneell mmaaiinn pprroocceessssoorr

ddooeess nnoott vveerriiffyy tthheerrmmoossttaatt ooppeerraattiioonn..

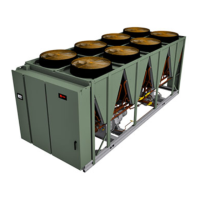

Table 13. Evaporator heater summary

Unit Size (tons)

Waterboxes

Supply

Return

2-pass Evaporator

150 to 165 400W 400W

180 to 200

400W (Qty 2)

400W

225 to 300 600W 600W

3-pass Evaporator

All sizes

400W (Qty 2)

400W

Chilled Water Pump Control

NNOOTTIICCEE

EEvvaappoorraattoorr DDaammaaggee!!

IIff tthhee mmiiccrroopprroocceessssoorr ccaallllss ffoorr aa ppuummpp ttoo ssttaarrtt aanndd

wwaatteerr ddooeess nnoott ffllooww,, tthhee eevvaappoorraattoorr mmaayy bbee

ddaammaaggeedd ccaattaassttrroopphhiiccaallllyy..

IItt iiss tthhee rreessppoonnssiibbiilliittyy ooff tthhee iinnssttaalllliinngg ccoonnttrraaccttoorr

aanndd//oorr tthhee ccuussttoommeerr ttoo eennssuurree tthhaatt aa ppuummpp wwiillll

aallwwaayyss bbee rruunnnniinngg wwhheenn ccaalllleedd uuppoonn bbyy tthhee cchhiilllleerr

ccoonnttrroollss..

An evaporator water pump output relay’s normally-

open contact closes to start the evaporator water pump

when the chiller is given a signal to go into the Auto

mode of operation from any source. The contact is

opened to turn off the pump in the event of most

machine level diagnostics to prevent the build up of

pump heat.

The relay output is required to operate the Evaporator

Water Pump (EWP) contactor. The relay’s contacts are

compatible with 115/240 VAC control circuits. See

Programmable Relays section for rating details.

Normally, the EWP relay follows the AUTO mode of the

chiller. Whenever the chiller has no diagnostics and is

in the AUTO mode, regardless of where the auto

command is coming from, the relay is energized and

the normally-open contact is closed. When the chiller

exits the AUTO mode, the relay’s normally-open

contact is timed to open in an adjustable (using

Tracer® TU service tool) 0 to 30 minutes. The non-

AUTO modes in which the pump is stopped, include

Reset, Stop, External Stop, Remote Display Stop,

Stopped by Tracer, Start Inhibited by Low Ambient

Temp, and Ice Building complete.

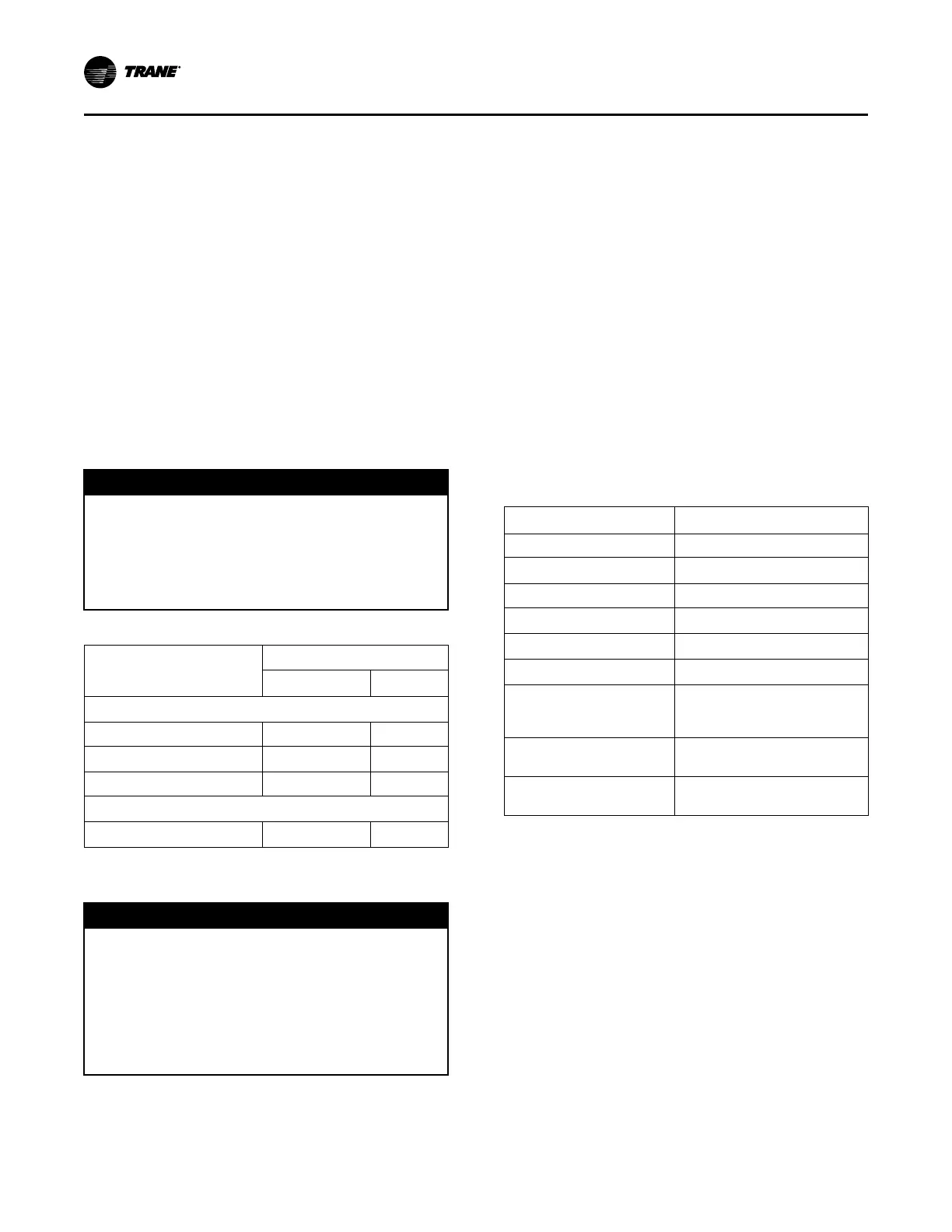

Table 14. Pump relay operation

Chiller Mode

Relay Operation

Auto Instant Close

Ice Building

Instant Close

Tracer Override Close

Stop Timed Open

Ice Complete Instant Open

Diagnostics Instant Operation

(a)

Chiller Shutdown

Diagnostics

(except freeze protection)

Instant Open

Freeze Protection related

chiller shutdown diagnostics

Initially: Remain Closed

Then: Delayed/Dependent Open

Chiller Off Cycle Freeze

Diagnostics

Instant Close – Dependent Open

(a)

Operation can be instant open or instant close, depending on

diagnostic.

When going from Stop to Auto, the EWP relay is

energized immediately. If evaporator water flow is not

established in 20 minutes (for normal transition) or 4

minutes, 15 seconds (for pump commanded ON due to

an override safety), the UC800 de-energizes the EWP

relay and generates a non-latching diagnostic. If flow

returns (e.g. someone else is controlling the pump), the

diagnostic is cleared, the EWP is re-energized, and

normal control resumed.

If evaporator water flow is lost once it had been

established, the EWP relay remains energized and a

non-latching diagnostic is generated. If flow returns,

the diagnostic is cleared and the chiller returns to

normal operation.

In general, when there is either a non-latching or

latching diagnostic, the EWP relay is turned off as

IInnssttaallllaattiioonn EElleeccttrriiccaall

Loading...

Loading...