AC-SVX001A-EN

71

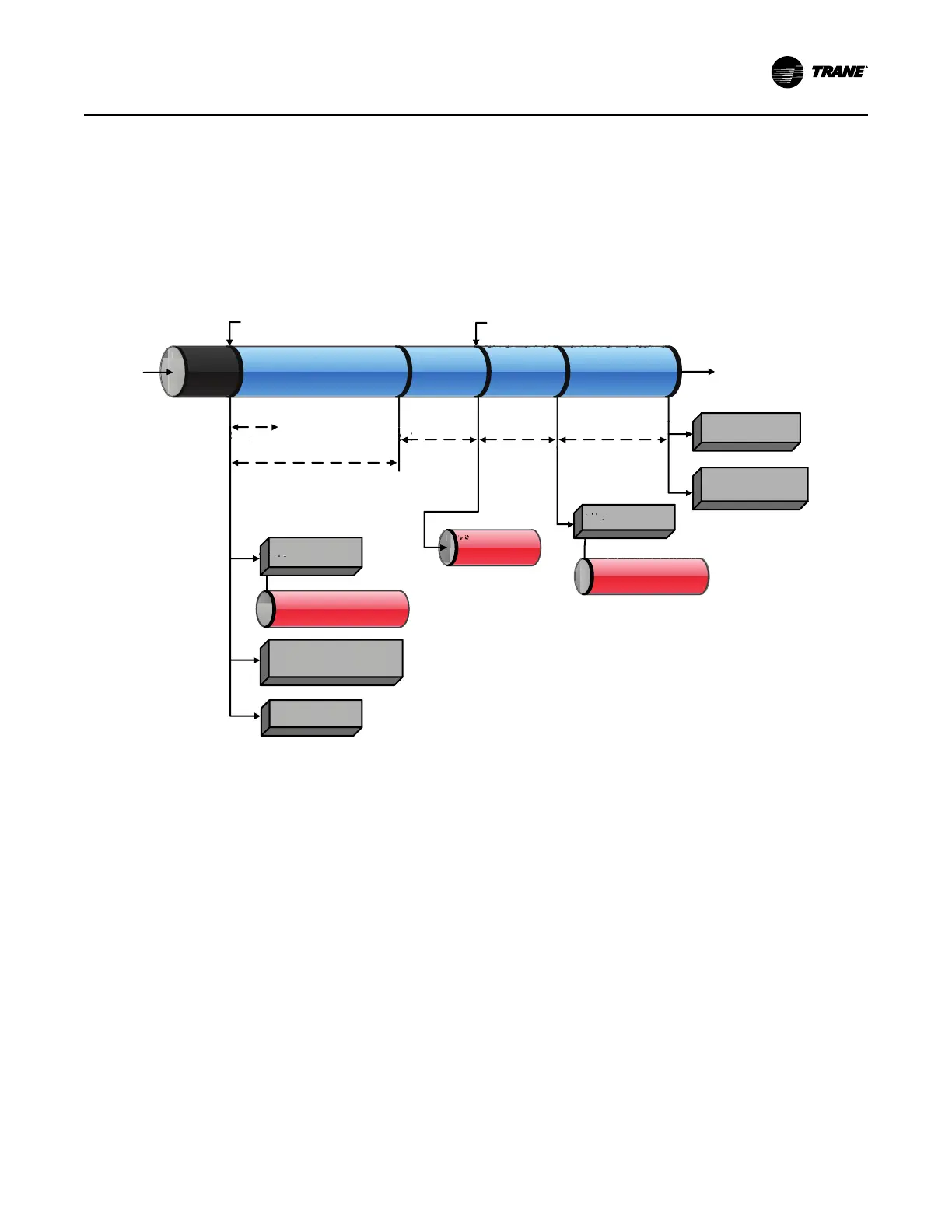

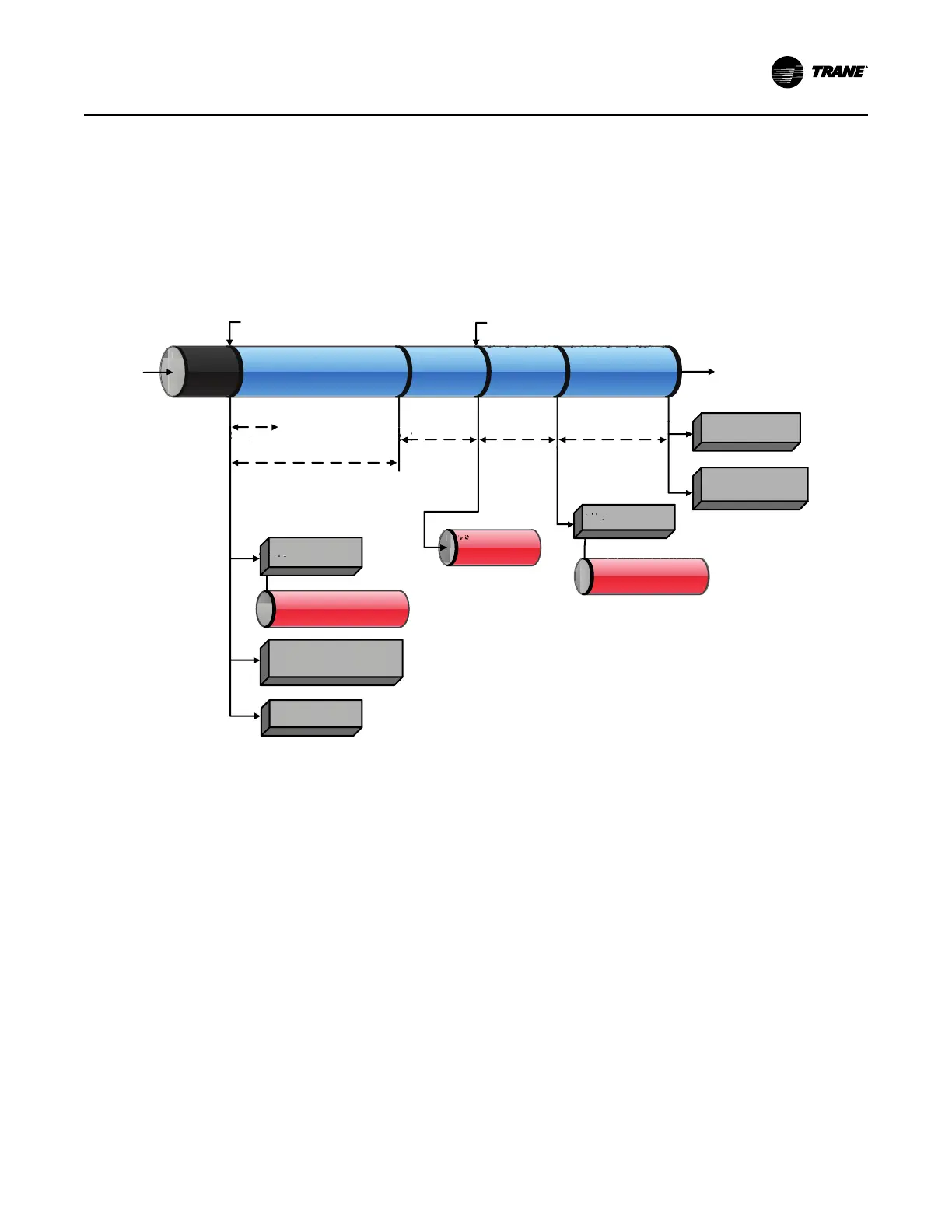

Stopped to Starting

The following diagram shows the timing from a

stopped mode to energizing the first compressor. The

shortest allowable time would be under the following

conditions:

• No motor restart inhibit time left from subsequent

starts

• Evaporator Water flow occurs quickly with pump on

command

• Need to cool (differential to start) already exists

• The above conditions would allow a compressor to

start in about 20 seconds.

Figure 53. Sequence of events: stopped to starting

Confirm Presence

of Oil W ithin

90 Seconds

Auto Mode com m anded

by Front Panel or BAS

Confirm Evaporator Water Flow

(6 Second Filter)

Enforce Restart Inhibit Timer

(0 to 1 minute)

Auto

Energize Evaporator

Water Pum p Relay

Confirm Evaporator Water

Flow W ithin 20 minutes

(6 Second Filter)

Oil Heaters

Always Energized when

Compressor is De-energized

EXV remains closed

Wait for Need

To Cool

(Diff to Start)

Call for Cooling

(Differential to Start is met)

Confirm

Presence of Oil

(0 to 90 seconds)

EXV m oving to

Preposition

0 to 25 Seconds

Send Start Command

to Lead Com pressor*

Transition to

Running

Start Control of

Condenser Fan Flow

Pre-Position EXV of

Lead Circuit

Check Evap Pressure for

Low Pressure Cutout

* Lead compressor (and its lead circuit) is

determined by staging algorithm - “Fixed Staging”

or “Balanced Wear” selection - also influenced by

lockouts, restart inhibit, or diagnostics present.

SSttaarrtt--uupp aanndd SShhuuttddoowwnn

Loading...

Loading...