Pre-Installation

14 AFDH-SVN004C-EN

Requirements for Installation

Technicians

To properly install an AFDH upgrade Adaptive Frequency

Drive package, the technician must have a good working

knowledge of the centrifugal chiller controller system

involved in the application. Training is highly

Recommended before beginning this upgrade.

Tools Required

Normal tools are required to perform the work. An HVAC

service technician with a well-stocked tool chest should

already have the majority of the normal tools needed for

this job.

In addition to the normally carried service tools and

hardware, the following is a partial list of specific field

supplied hardware and software components and special

tools that will also be required to perform the drive

upgrade:

• The

appropriate lifting device or devices (including

all necessary rigging hardware) with the capacity to

safely lift up to 1500 lb.

Important: A

spreader bar will be required if the drive

unit will be hoisted into position using a

single lifting device that is capable of

making only a single-point lift.

• Torque

wrench capable of 40-170 foot-pounds.

• A

PC or laptop computer equipped with the correct

software tools for the chiller controller involved in

the application.

– Tracer TU service software version 10.2.174 or

newer.

Note: Refer to BAS-SVP04*-EN (Programming Guide:

TR200) for full program parameter details and

descriptions, and the instructions necessary to

operate the Local Control Panel (LCP) and program

the necessary drive parameters.

Note: The

most current CTV and CVR microprocessor

(MP) firmware files are included with the program

files for the Tracer TU service software tools.

• Type

A to TypeB USB cable to connect the computer

to a Tracer UC800 controller.

• South

pole magnet screwdriver (TOL01343).

Miscellaneous Field-Provided

Material

Some field provided material will be required to perform

the drive upgrade. A partial list of material is provided here

to help the technician to plan ahead and to avoid material

shortages at the job site.

• Self-adhesive

cable tie mounting bases and cable

ties.

– Used to help “clean up” wiring runs during the

installation

process.

• Loctite

®

554 thread sealant for refrigerant

applications (Trane part number SEL00528).

– Used in applications where a pressure

transducer

needs to be installed.

• For

Direct Mount Drive install, have 3" X 3" Slotted

Shim Full Assortment Kit available.

– Used to shim between the enclosure and the

evaporator

attached bracket.

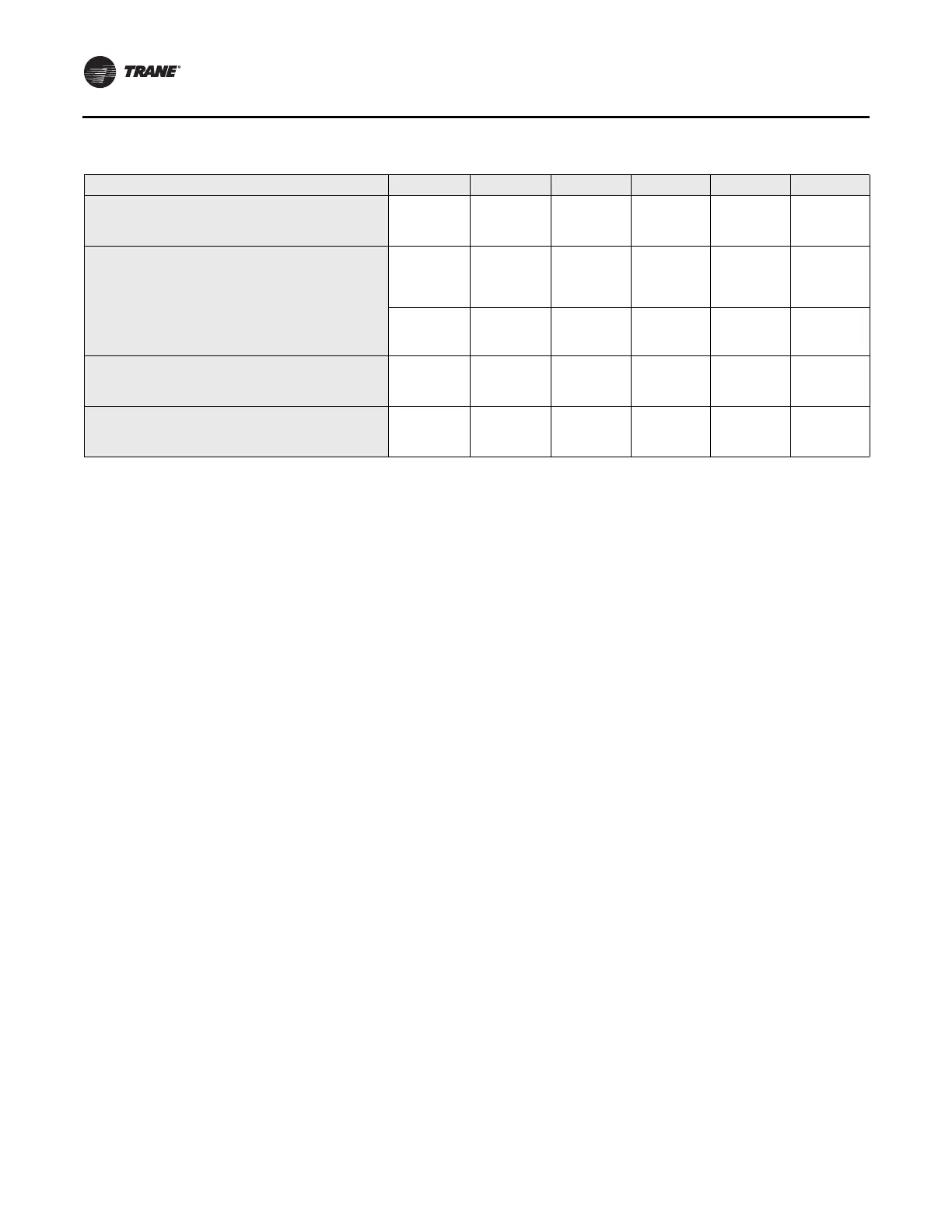

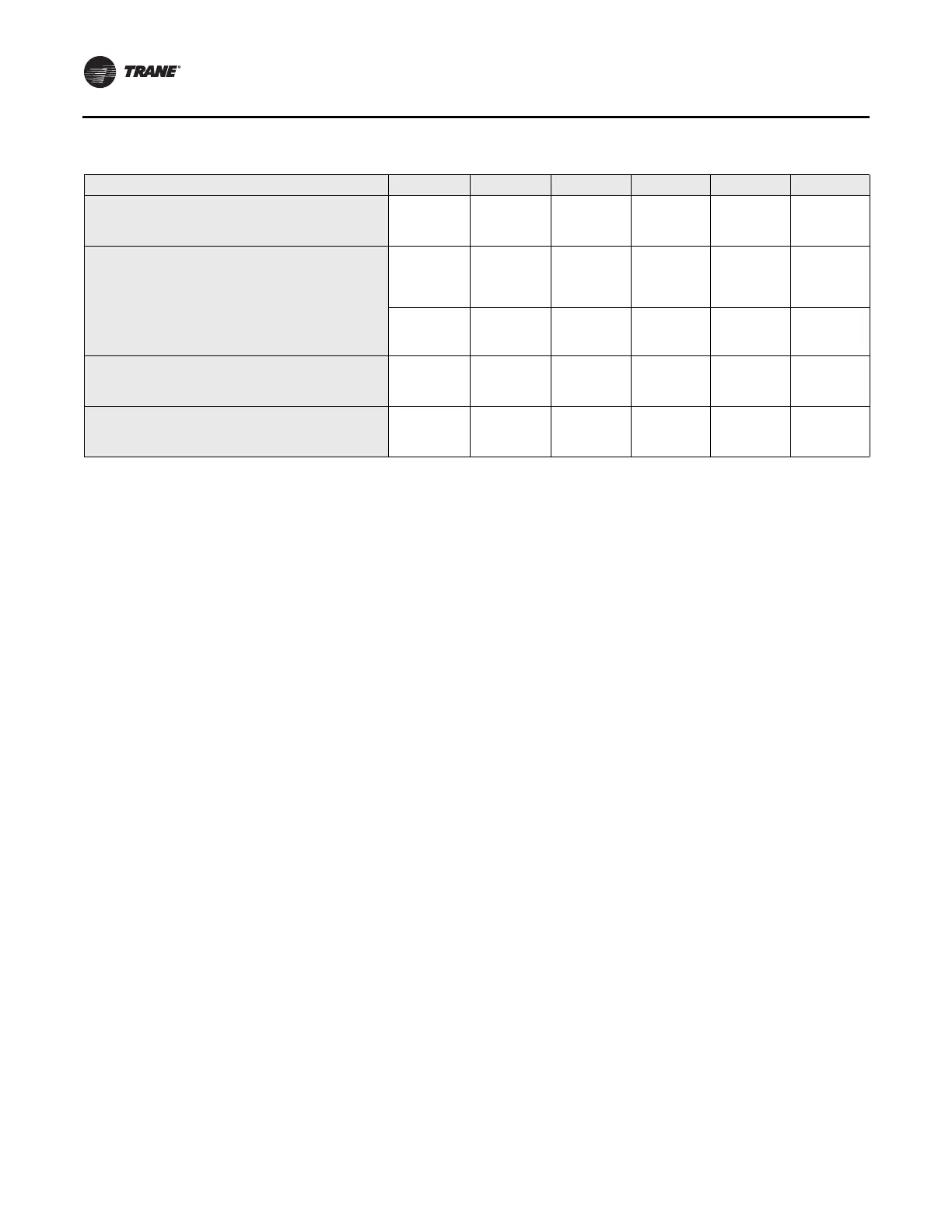

Table 4. Input/output power wire cable sizes AFDH E-Frame drives (575V/600V)

575V/600V E-Frame AFDH Maximum amps 450 500 570 630 730 850

INCOMING POWER TO DRIVE CIRCUIT

BREAKER: Number of Cable Lugs per Phase and

Range of Wire Sizes Standard Lugs Will Accept

Four wire lugs

4/0-500 KCmil

Four wire lugs

4/0-500

KCmil

Four wire lugs

4/0-500

KCmil

Four wire lugs

4/0-500

KCmil

Four wire lugs

4/0-500

KCmil

Four wire lugs

4/0-500

KCmil

INCOMING POWER TO DRIVE CIRCUIT

BREAKER: Number of Cable Lugs per Phase and

Range of Wire Sizes Optional Lugs Will Accept

Three wire

lugs

500-750

KCmil

Three wire

lugs

500-750

KCmil

Three wire

lugs

500-750

KCmil

Three wire

lugs

500-750

KCmil

Three wire

lugs

500-750

KCmil

Three wire

lugs

500-750

KCmil

Four wire lugs

3/0-400 KCmil

Four wire lugs

3/0-400

KCmil

Four wire lugs

3/0-400

KCmil

Four wire lugs

3/0-400

KCmil

Four wire lugs

3/0-400

KCmil

Four wire lugs

3/0-400

KCmil

PHASE WIRE BETWEEN DRIVE AND CB:

Number of Wire Cable Per Phase and Size of

Factory Installed Wires

Two

4/0 DLO

wires

Two

4/0 DLO

wires

Two

313 MCM DLO

wires

Three

4/0 DLO wires

Three

4/0 DLO

wires

Three

313 MCM DLO

wires

OUTPUT POWER TO COMPRESSOR MOTOR:

Number of Wire Cable Per Phase and Size of

Factory Installed Wires

Two

4/0 DLO

wires

Two

4/0 DLO

wires

Two

313 MCM DLO

wires

Three

4/0 DLO

wires

Three

4/0 DLO

wires

Three

313 MCM DLO

wires

Loading...

Loading...