Installation

50 AFDH-SVN004C-EN

Important: If the chiller does not already have a

condenser pressure transducer. Do not

forget to install the condenser pressure

transducer provided in the Tracer®

AdaptiView™ Miscellaneous Hardware

Package. The accurate pressure readings

required by the chiller controls to enable the

most efficient operation of the chiller with

the upgraded AFDH drive can only be

effectively measured with a pressure

transducer.

Required Reprogramming of

Tracer® AdaptiView™ Controls.

Reprogramming Factory Installed Tracer®

AdaptiView™ Controls (CTV Simplex

Firmware)

Important: Make sure your laptop is loaded with the

most current version of Tracer TU tool

software so that you have the most up-to-

date version of CTV MP firmware available

to install into the UC800.

Note: CTV

MP firmware is always used in factory installed

Tracer® AdaptiView™ control systems or in

Tracer® AdaptiView™ display upgrades to factory

installed CH530 control systems.

1. Factory installed wiring

2. Field installed wiring

3.

Note: Actual wire designators may vary depending upon the specific model/version of chiller control that the AFDH drive is being linked with.

Please refer to the original chiller control wiring diagrams and the wire descriptions listed in Figure Callouts 4–11 if an actual wire designator

does not match the one shown in this graphic.

4. 115VAC feed to chiller control panel

5. Neutral feed to chiller control panel

6. Normally Closed terminal(2) on HPC (High Pressure Cutout) switch (3S1) for original chiller with starter module and/or non-comm. Drive

terminal 4 is 115VAC only.

Note: For original chillers with a communicating drive, high pressure cutout wiring is 24V. For original chillers with a starter module, high pressure cutout

wiring is 115V.

7. From 1A7 J2-4 oil pump LLID

8. From 1A7 J2-2 oil LLID or could come from the 1X1 terminal block

9. and 10. Normal closed terminal on HPC switch (3S1) for original chiller with comm. Drive terminals 9 and 10 are 24VDC only.

Note: For original chillers with a communicating drive, high pressure cutout wiring is 24V.

11. 12. and 13. From UC800 IMC Modbus link

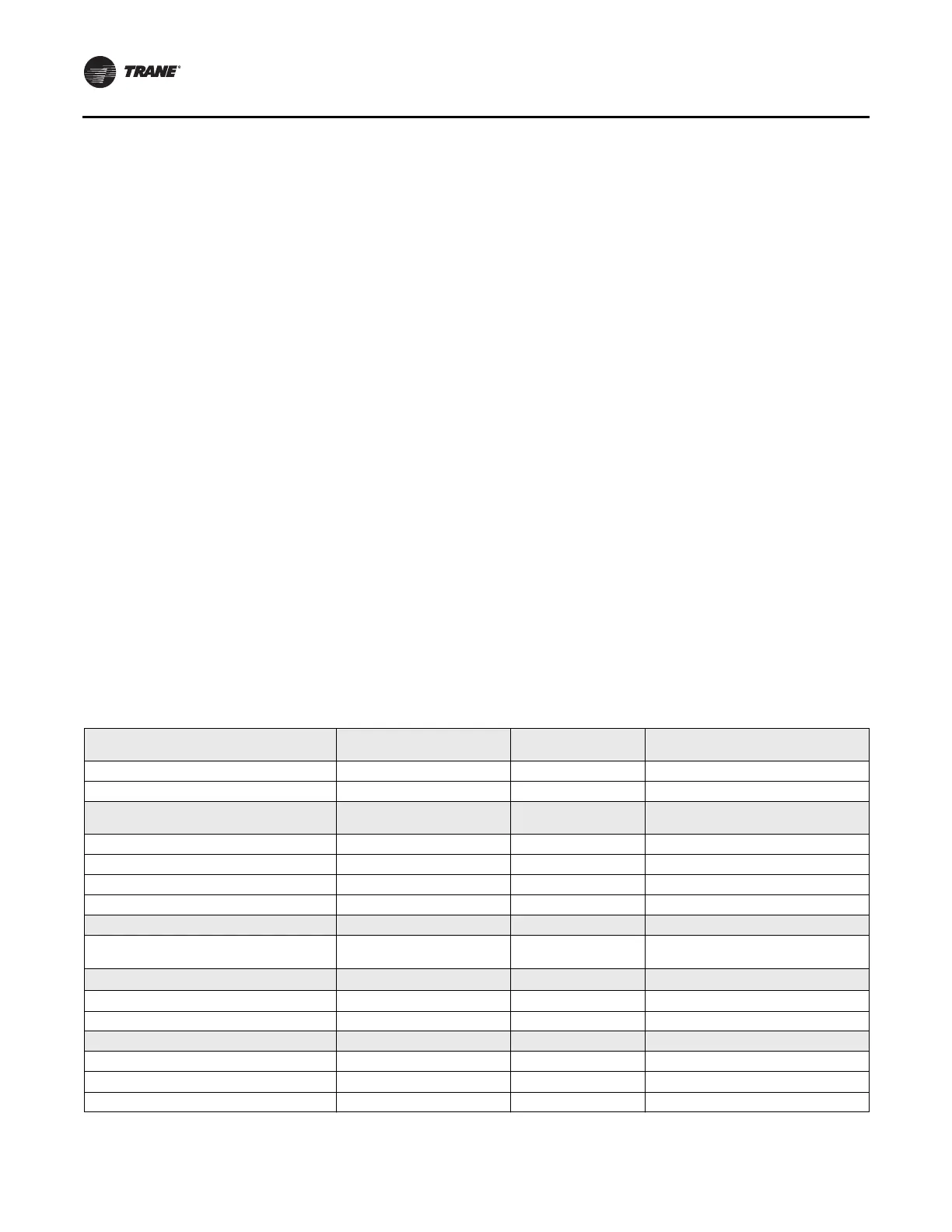

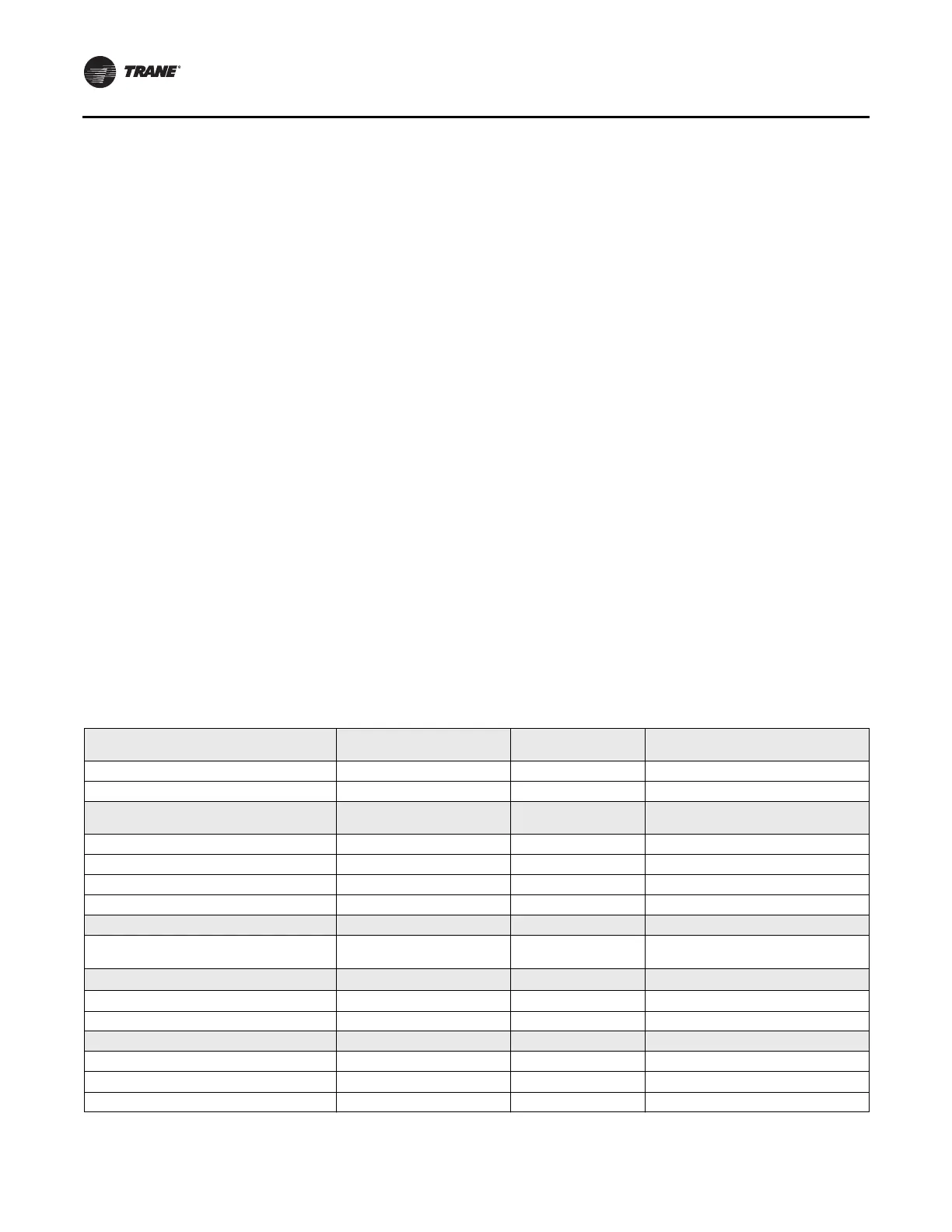

Table 26. UC800/Tracer® AdaptiView™ CTV parameter values with upgrade AFDH

Tracer TU Service Setpoints View:

Adjustable Frequency Drive Setpoints

Range Default Setting Recommended Setting

AF Control Auto, Fixed Auto Auto

ReOptimization Sensitivity 0–100% 20 20

Tracer TU Field Startup View:

Adjustable Frequency Drive

Range Default Setting Recommended Setting

AFD Temperature Limit Setpoint 0.0 - 360.0 212.0 212.0

Maximum Frequency 30–60 Hz 60 60

Minimum Frequency 30–60 Hz 38 38

Surge Speed Increase 0–2 Hz 1 1

Tracer TU Configuration View: Main Range Default Setting Recommended Setting

Unit Type (MODL) CVHE, CVHF, CVHG, CVGF CVHE

Enter Chiller Model from Unit Nameplate

(Note: only CVHE or CVHF apply)

Tracer TU Configuration View: UC800

Range Default Setting Recommended Setting

Starter Type Not Applicable Unit Mount Wye-Delta TR200 Modbus AFD

Impeller Diameter (CPIM) 50-345 275 Enter CPIM from Unit Nameplate

Tracer TU Configuration View: Starter Range Default Setting Recommended Setting

Unit Line Voltage 180–15000V 460 Enter from Unit Nameplate

Motor NP Power 4000 kW 400 Enter from Unit Nameplate

Motor Temperature Protection Type 75 Ohm@75F, 100 Ohm@ 0C 75 ohm 75 ohm

Loading...

Loading...