RT-SVX072A-EN

131

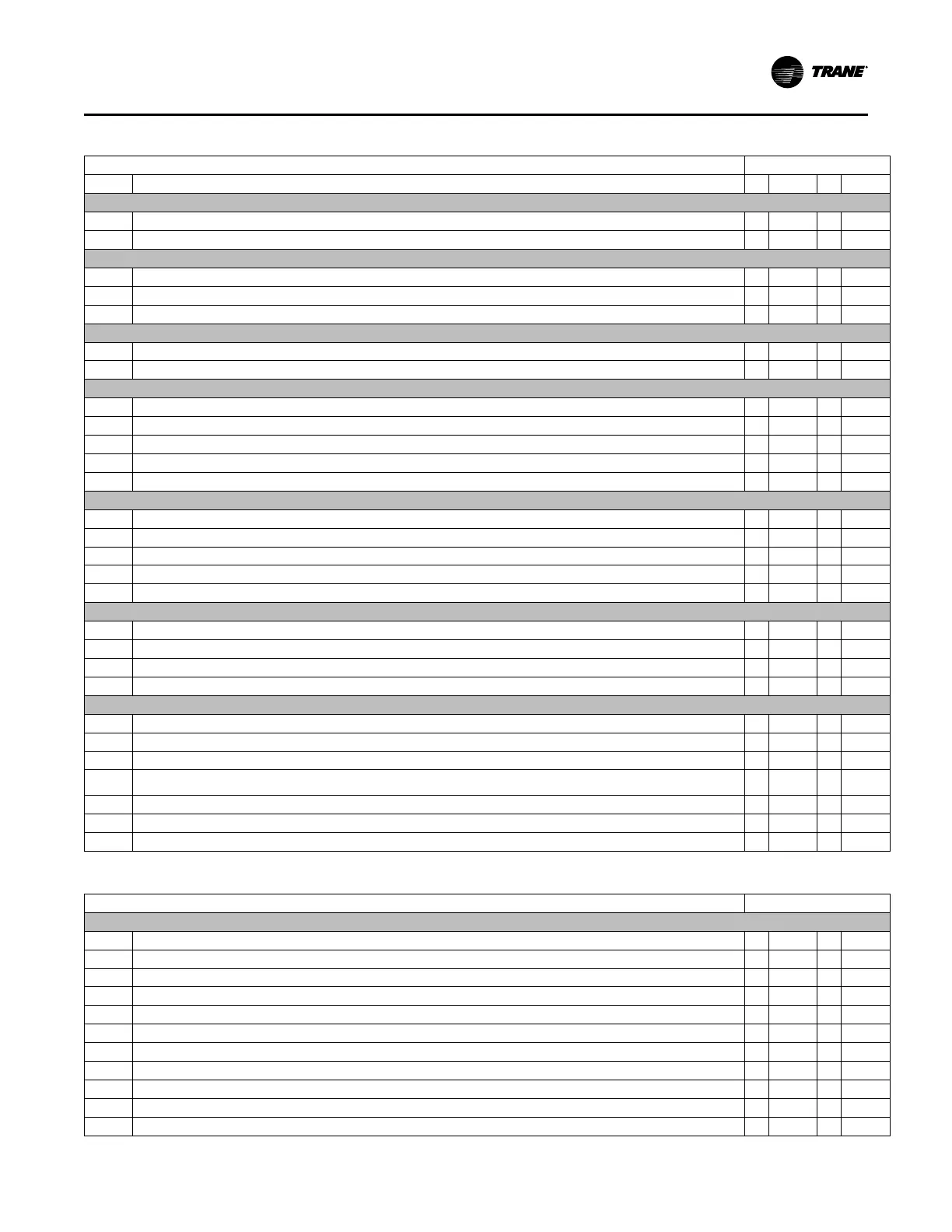

Table 59. Startup checklist for 20–75 ton air-cooled units (continued)

Completed?

32

Verify fan amperages within nameplate specs (please document on log sheet)

Yes No

Unit Configuration and Setup

1

Verify model number in the UCM configuration matches unit model number on nameplate

Yes No

2

Configure unit using IOM and critical control parameters using critical control parameters table

Yes No

Air Cooled Condenser (Digit 27)

1

All coil fins inspected and straightened

Yes No

2

Condenser fans are rotating freely

Yes No

3

Verify the fan blade set-screws to the motor shaft of the condenser fan assemblies are tight

Yes No

Electric Heat (if applicable)

1

Electric heat circuits have continuity

Yes No

2

Perform electric heat start up procedure

Yes No

Gas Heat (if applicable)

1

Gas heat piping includes drip leg previously installed by installing contractor

Yes No

2

Gas heat flue assembly fully installed

Yes No

3

Gas heat condensate line and heat tape installed where applicable

Yes No

4

Verify heating system matches name plate

Yes No

5

Perform gas heat start up procedure in IOM

Hot Water Heat (if applicable)

1

Verify hot water pipes are proper size, routed through the base and no leaks are present

Yes No

2

Verify swing joints or flexible connectors are installed next to hot water coil

Yes No

3

Verify gate valve is installed in the supply and return branch line

Yes No

4

Verify three way modulating valve is installed with valve seating against the flow

Yes No

5

Verify coil venting is installed if water velocity is less than 1.5 feet per second

Yes No

Steam Water Heat (if applicable)

1

Verify steam pipes are proper size, routed through the base and no leaks are present

Yes No

2

Verify steam heat swing check vacuum breakers installed and vented

Yes No

3

Verify 2-way modulating valve has been installed

Yes No

4

Verify steam trap installed properly with discharge 12” below the outlet connection on the coil

Yes No

System Checkout

1

Verify system airflow

Yes No

2

Verify dampers open and close properly

Yes No

3

Adjust fresh air damper travel

Yes No

4

Verify compressor operation, voltage and amperage matches name plate information (please document on log

sheet)

Yes No

5

Operating log completed

Yes No

6

All panels & doors secured

Yes No

7

Complete all required documentation

Yes No

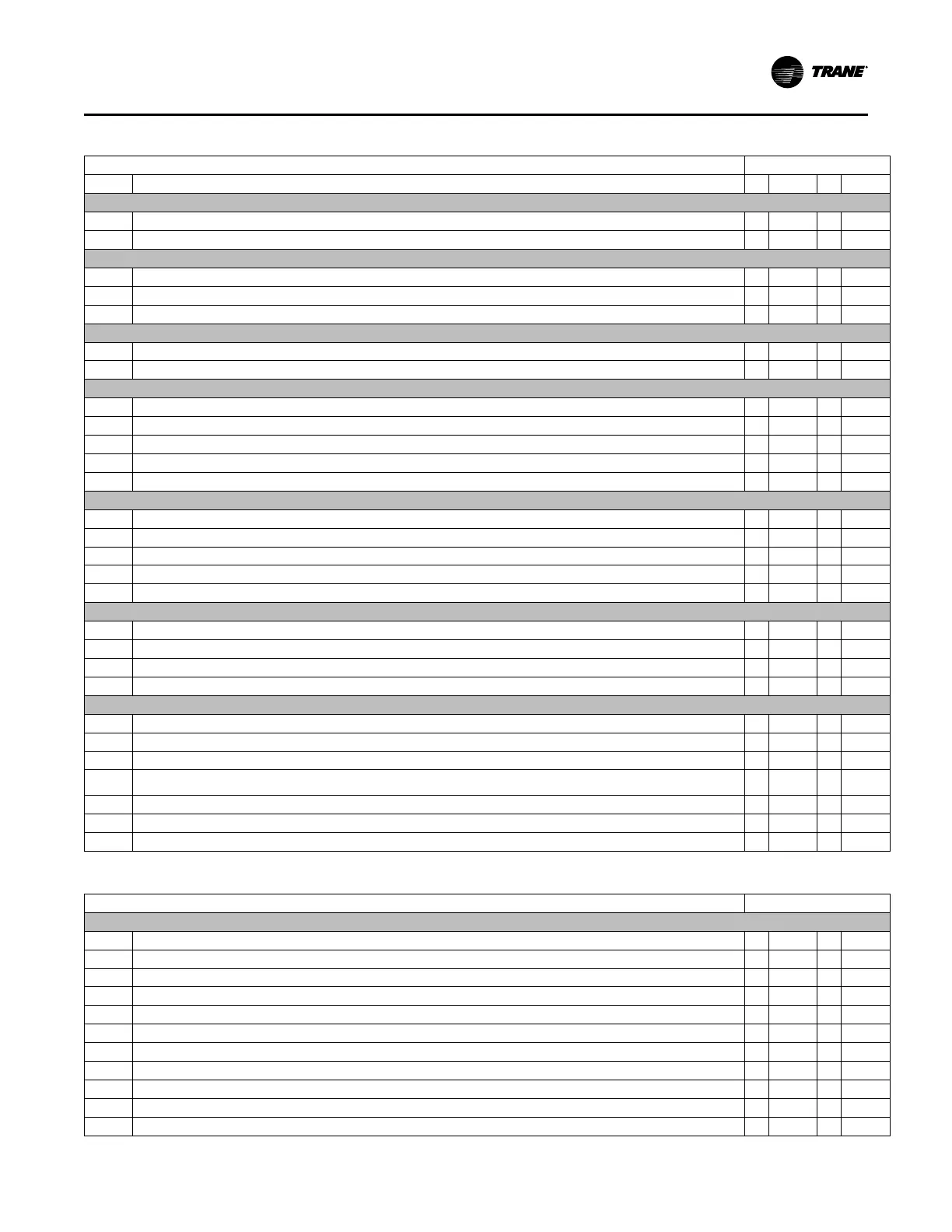

Table 60. Startup checklist for 90–130 ton air-cooled units

Completed?

General Start-up

1

Is adequate access/egress provided?

Yes No

2

Initial site inspection performed?

Yes No

3

Unit exterior inspected for damage (dents, bends, missing panels, doors work properly)?

Yes No

4

Unit clearances adequate to avoid air recirculation?

Yes No

5 Wear electrical PPE Yes No

6

Lockout & tagout unit

Yes No

7

Verify unit interior is free from debris and obstructions, etc.

Yes No

8

All unit drain lines and traps are properly installed

Yes No

9

Remove electrical access panel fastened (9) bolt/screws or open access

Yes No

10

Verify unit is grounded. Confirm a ground wire is coming from the power source

Yes No

11

Verify main power feed wire gauge is properly sized for current load

Yes No

TTrraannee SSttaarrttuupp CChheecckklliisstt

Loading...

Loading...