132

RT-SVX072A-EN

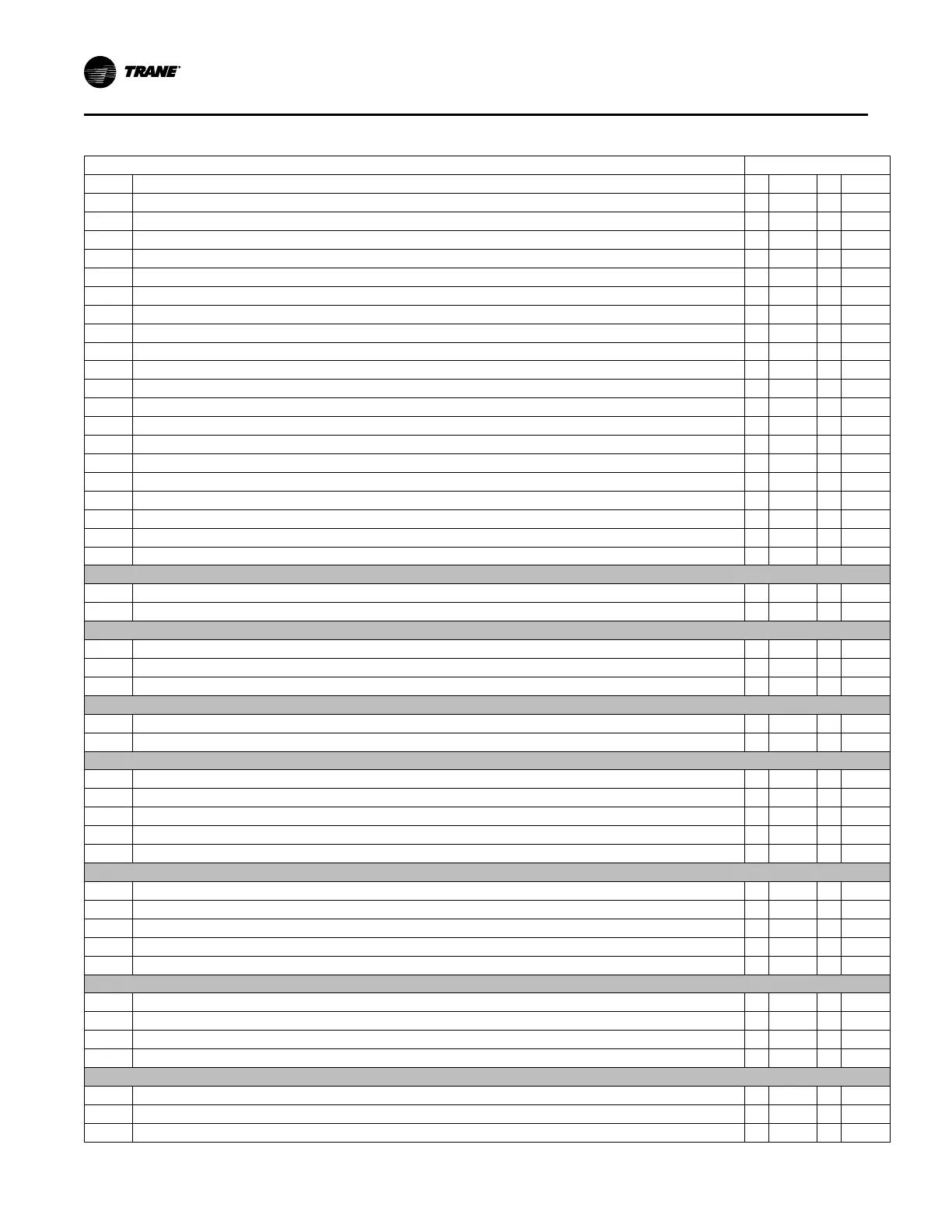

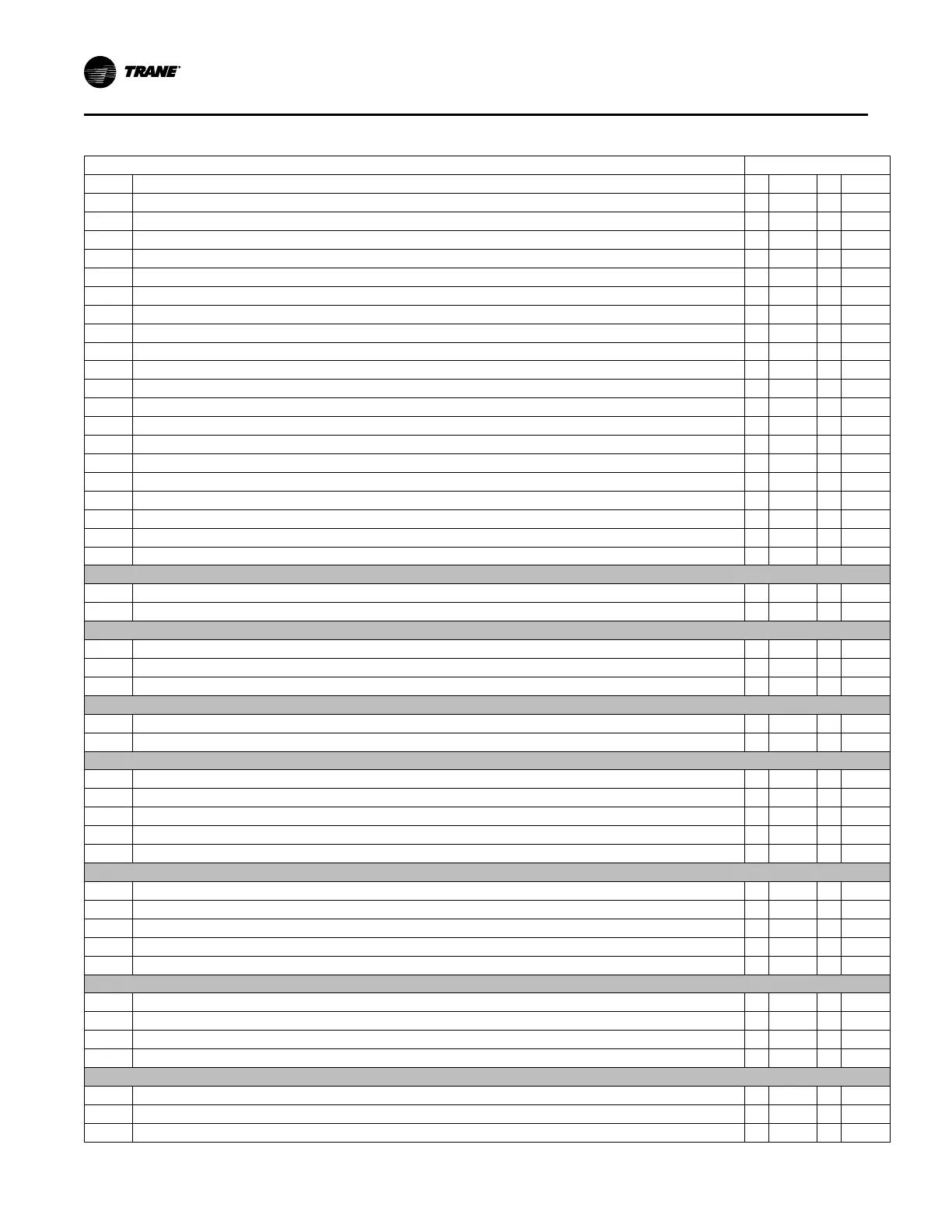

Table 60. Startup checklist for 90–130 ton air-cooled units (continued)

Completed?

12

Verify all wiring connections are tight

Yes No

13

Verify all field control wiring for VAV controls are complete

Yes No

14

Verify all automation and remote controls installed/wired

Yes No

15

Verify all shipping hardware and plastic covers for compressors have been removed

Yes No

16

Verify hold down bolts and channels from fan sections removed

Yes No

17

Fan section isolators checked/adjusted (approx ¼” gap above shipping block)

Yes No

18

Verify damper linkages are tight/adjusted and tip seals are in good condition

Yes No

19

Verify compressor oil levels at proper levels (½ - ¾ high in glass)

Yes No

20

Compressor discharge service valves and oil valves open/back seated

Yes No

21

All fan belts tensioned, bearings greased and sheaves in alignment

Yes No

22

Verify supply and relief fan pulley bolts are tight

Yes No

23

Verify fans rotate freely

Yes No

24

Verify refrigerant charge on each circuit

Yes No

25

Remove lock tag out

Yes No

26 Wear electrical PPE Yes No

27

Verify correct voltage supplied to unit and electrical heaters (see IOM for assistance)

Yes No

28

Allow compressor crankcase heaters to operate for 8 hours prior to starting the refrigeration system.

Yes No

29

Verify incoming voltage phase balanced

Yes No

30

Check the incoming power phase rotation.

Yes No

31

Verify all fans rotate in proper direction

Yes No

32

Verify fan amperages within nameplate specs (please document on log sheet)

Yes No

Unit Configuration and Setup

1

Verify model number in the UCM configuration matches unit model number on nameplate

Yes No

2

Configure unit using IOM and critical control parameters using critical control parameters table

Yes No

Air Cooled Condenser (Digit 27)

1

All coil fins inspected and straightened

Yes No

2

Condenser fans are rotating freely

Yes No

3

Verify the fan blade set-screws to the motor shaft of the condenser fan assemblies are tight

Yes No

Electric Heat (if applicable)

1

Electric heat circuits have continuity

Yes No

2

Perform electric heat start up procedure

Yes No

Gas Heat (if applicable)

1

Gas heat piping includes drip leg previously installed by installing contractor

Yes No

2

Gas heat flue assembly fully installed

Yes No

3

Gas heat condensate line and heat tape installed where applicable

Yes No

4

Verify heating system matches name plate

Yes No

5

Perform gas heart start up procedure in IOM

Hot Water Heat (if applicable)

1

Verify hot water pipes are proper size, routed through the base and no leaks are present

Yes No

2

Verify swing joints or flexible connectors are installed next to hot water coil

Yes No

3

Verify gate valve is installed in the supply and return branch line

Yes No

4

Verify three way modulating valve is installed with valve seating against the flow

Yes No

5

Verify coil venting is installed if water velocity is less than 1.5 feet per second

Yes No

Steam Water Heat (if applicable)

1

Verify steam pipes are proper size, routed through the base and no leaks are present

Yes No

2

Verify steam heat swing check vacuum breakers installed and vented

Yes No

3

Verify 2-way modulating valve has been installed

Yes No

4

Verify steam trap installed properly with discharge 12” below the outlet connection on the coil

Yes No

System Checkout

1

Verify system airflow

Yes No

2

Verify dampers open and close properly

Yes No

3

Adjust fresh air damper travel

Yes No

TTrraannee SSttaarrttuupp CChheecckklliisstt

Loading...

Loading...