30

RT-SVX072A-EN

Installation

Roof Curb and Ductwork

The roof curbs consist of two main components: a

pedestal to support the unit condenser section and a

“full perimeter” enclosure to support the unit’s air

handler section.

Before installing any roof curb, verify the following:

• It is the correct curb for the unit.

• It includes the necessary gaskets and hardware.

• The purposed installation location provides the

required clearance for proper operation.

• The curb is level and square — the top surface of

the curb must be true to assure an adequate curb-

to-unit seal.

Step-by-step curb assembly and installation

instructions ship with each Trane accessory roof curb

kit. Follow the instructions carefully to assure proper

fit-up when the unit is set into place.

NNoottee:: To assure proper condensate flow during

operation, the unit (and curb) must be as level as

possible. The maximum slope allowable for

rooftop unit applicationsexcluding SSH_s, is 4"

end-to-end and 2" side-to-side. Units with steam

coils (SSH_s) must be set level!

If the unit is elevated, a field constructed catwalk

around the unit is strongly recommended to provide

easy access for unit maintenance and service.

Recommendations for installing the Supply Air and

Return Air ductwork joining the roof curb are included

in the curb instruction booklet. Curb ductwork must be

fabricated and installed by the installing contractor

before the unit is set into place.

NNoottee:: For sound consideration, cut only the holes in the

roof deck for the ductwork penetrations. Do not

cut out the entire roof deck within the curb

perimeter.

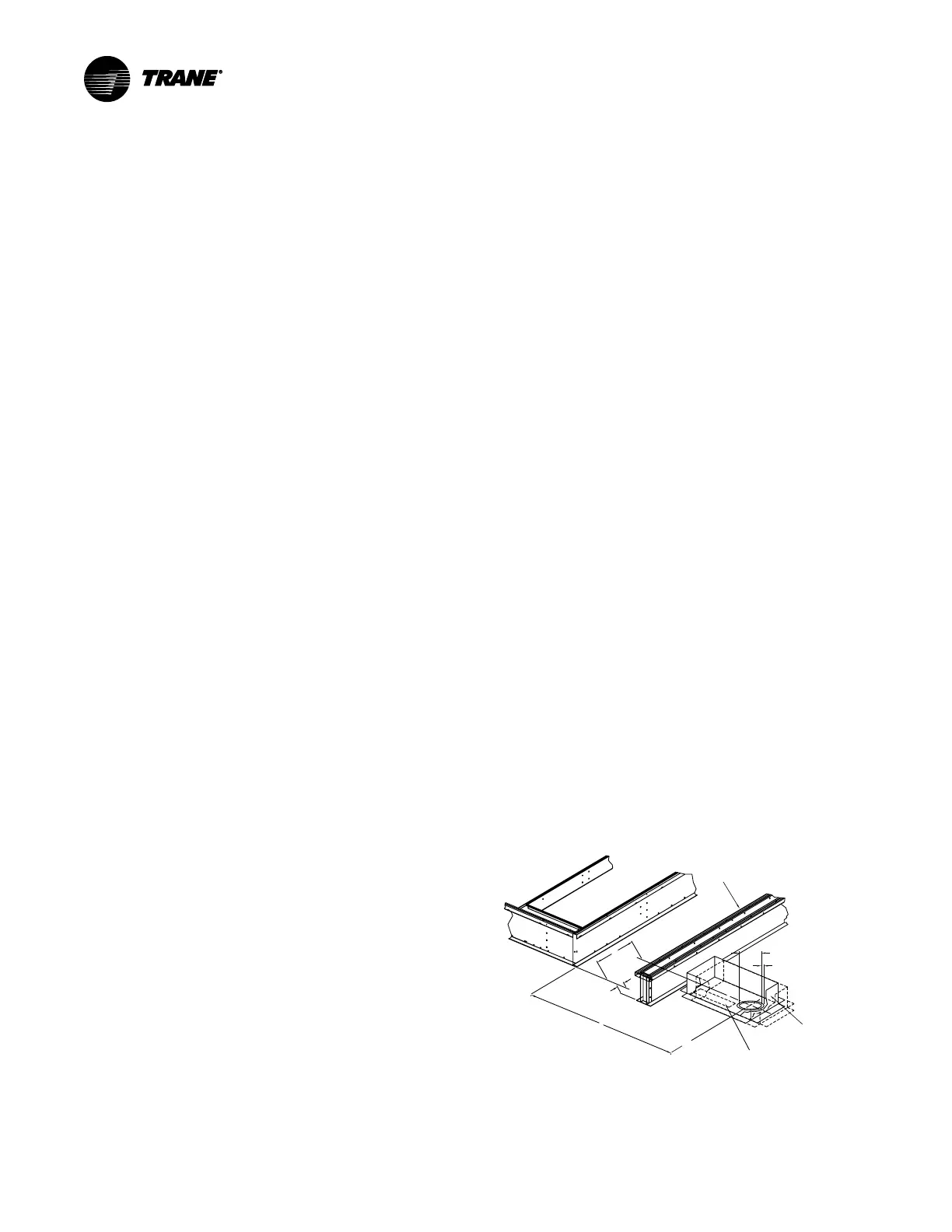

Pitch Pocket Location

The location of the main supply power entry is located

at the bottom right-hand corner of the control panel.

illustrates the location for the electrical entrance

through the base in order to enter the control panel. If

the power supply conduit penetrates the building roof

beneath this opening, it is recommended that a pitch

pocket be installed before the unit is placed onto the

roof curb.

The center line dimensions shown in the illustration

below indicates the center line of the electrical access

hole in the unit base when it is positioned on the curb,

±3/8 inch. The actual diameter of the hole in the roof

should be at least 1/2 inch larger than the diameter of

the conduit penetrating the roof. This will allow for the

clearance variable between the roof curb rail and the

unit base rail illustrated in Figure 10, p. 30.

The pitch pocket dimensions listed are recommended

to enhance the application of roofing pitch after the

unit is set into place. The pitch pocket may need to be

shifted as illustrated to prevent interference with the

curb pedestal.

If a Trane Curb Accessory Kit is not used:

• The ductwork can be attached directly to the

factory-provided flanges around the unit supply

and return air openings. Be sure to use flexible duct

connections at the unit.

• For “built-up” curbs supplied by others, gaskets

must be installed around the curb perimeter flange

and the supply and return air opening flanges.

• If a “built-up” curb is provided by others, it should

NOT be made of wood.

• If a “built-up” curb is provided by others, keep in

mind that these commercial rooftop units do not

have base pans in the condenser section.

• If this is a REPLACEMENT UNIT without the IRU

option, keep in mind that the CURRENT DESIGN

commercial rooftop units do not have base pans in

the condenser section.

• Trane roof curbs are recommended. If using a non-

Trane roof curb with right-angle return airflow

approaches to a return fan inlet, a rigid, solid flow

baffle wall should be installed across the full width

of the roof curb return airflow path in the position

shown in Figure 16, p. 37 to reduce potential

airflow disturbances at the return fan inlet that

could contribute to unusual return fan noise.

• If a full perimeter curb is used, make sure the IRU

option was added to the unit to ensure stability in

the condenser section

Figure 10. Pitch pocket location

S

upply Air Opening

Pedestal

Conduit Diameter

Roof Curb

Cut-a-Way

4-13/16”

1/2” Clearance

Pitch Pocket

16” x 8”

*Control Wire Conduit

Access Area (Illustration Only)

C

L

C

B

A

L

Loading...

Loading...