RT-SVX072A-EN

63

Main Electrical Power

Lock and tag out unit main electric power and remove

power supply wiring from installed disconnect/terminal

block of unit. See for locations.

NNoottee:: Inspect wiring to ensure that all field-installed

wiring complies with NEC and applicable local

codes.

SEHF Units with 200V or 230V Electric

Heat

(Requires separate power supply to heater)

Lock and tag out unit main electric power and remove

power supply wiring for the electric heat from a

dedicated, field- supplied/installed disconnect to

terminal block, or to an optional unit-mounted

disconnect switch. See for locations.

Field-installed Control Wiring

NNoottee:: Inspect wiring to ensure that all field-installed

wiring complies with NEC and applicable local

codes.

Remove the field wiring connections for the variable air

volume controls as applicable.

NNoottee:: Label wiring to save time when reconnecting

wiring is necessary.

Remove ground wire from the unit.

NNoottee:: The electrical connection for 40, 60, 70 and 75 ton

is 32 inches further down the unit than older

(pre-2010) style units. On full perimeter curbs,

this also means the incoming electrical will be

outside the curb area. The electrician should be

informed of both points.

See for typical field wiring for 20-75 ton units. See

Figure 32, p. 52 for typical field power wiring for 90-130

ton units.

Requirements for Gas Heat

WWAARRNNIINNGG

HHaazzaarrddoouuss GGaasseess aanndd FFllaammmmaabbllee

VVaappoorrss!!

FFaaiilluurree ttoo oobbsseerrvvee tthhee ffoolllloowwiinngg iinnssttrruuccttiioonnss ccoouulldd

rreessuulltt iinn eexxppoossuurree ttoo hhaazzaarrddoouuss ggaasseess,, ffuueell

ssuubbssttaanncceess,, oorr ssuubbssttaanncceess ffrroomm iinnccoommpplleettee

ccoommbbuussttiioonn,, wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy.. TThhee ssttaattee ooff CCaalliiffoorrnniiaa hhaass ddeetteerrmmiinneedd tthhaatt

tthheessee ssuubbssttaanncceess mmaayy ccaauussee ccaanncceerr,, bbiirrtthh ddeeffeeccttss,,

oorr ootthheerr rreepprroodduuccttiivvee hhaarrmm..

IImmpprrooppeerr iinnssttaallllaattiioonn,, aaddjjuussttmmeenntt,, aalltteerraattiioonn,,

sseerrvviiccee oorr uussee ooff tthhiiss pprroodduucctt ccoouulldd ccaauussee

ffllaammmmaabbllee mmiixxttuurreess oorr lleeaadd ttoo eexxcceessssiivvee ccaarrbboonn

mmoonnooxxiiddee.. TToo aavvooiidd hhaazzaarrddoouuss ggaasseess aanndd

ffllaammmmaabbllee vvaappoorrss ffoollllooww pprrooppeerr iinnssttaallllaattiioonn aanndd

sseettuupp ooff tthhiiss pprroodduucctt aanndd aallll wwaarrnniinnggss aass pprroovviiddeedd

iinn tthhiiss mmaannuuaall..

1. Remove and isolate gas supply from the unit gas

train.

2. Ensure gas supply line piping joints are properly

sealed.

3. Remove drip leg Installed in the gas piping near the

unit.

4. Remove factory-supplied flue assembly installed on

the unit.

5. Remove the 3/4" CPVC furnace drain stub out that

was used for condensate drain.

Requirements for Hot Water Heat (SLH*)

1. Remove and isolate water piping that comes into

the heating section from the base of the unit.

2. Remove the installed, 3-way modulating valve, if

necessary, to remove unit.

3. Remove the valve actuator wiring.

Requirements for Steam Heat (SSH*)

1. Remove and isolate steam piping that comes into

the heating section from the base of the unit.

2. Remove, 2-way modulating valve if necessary.

3. Remove the valve actuator wiring.

Space Pressure Sensor and Tubing

Installation

(All units with Statitrac)

Remove field-supplied pneumatic tubing connected to

the space pressure transducer located in the filter

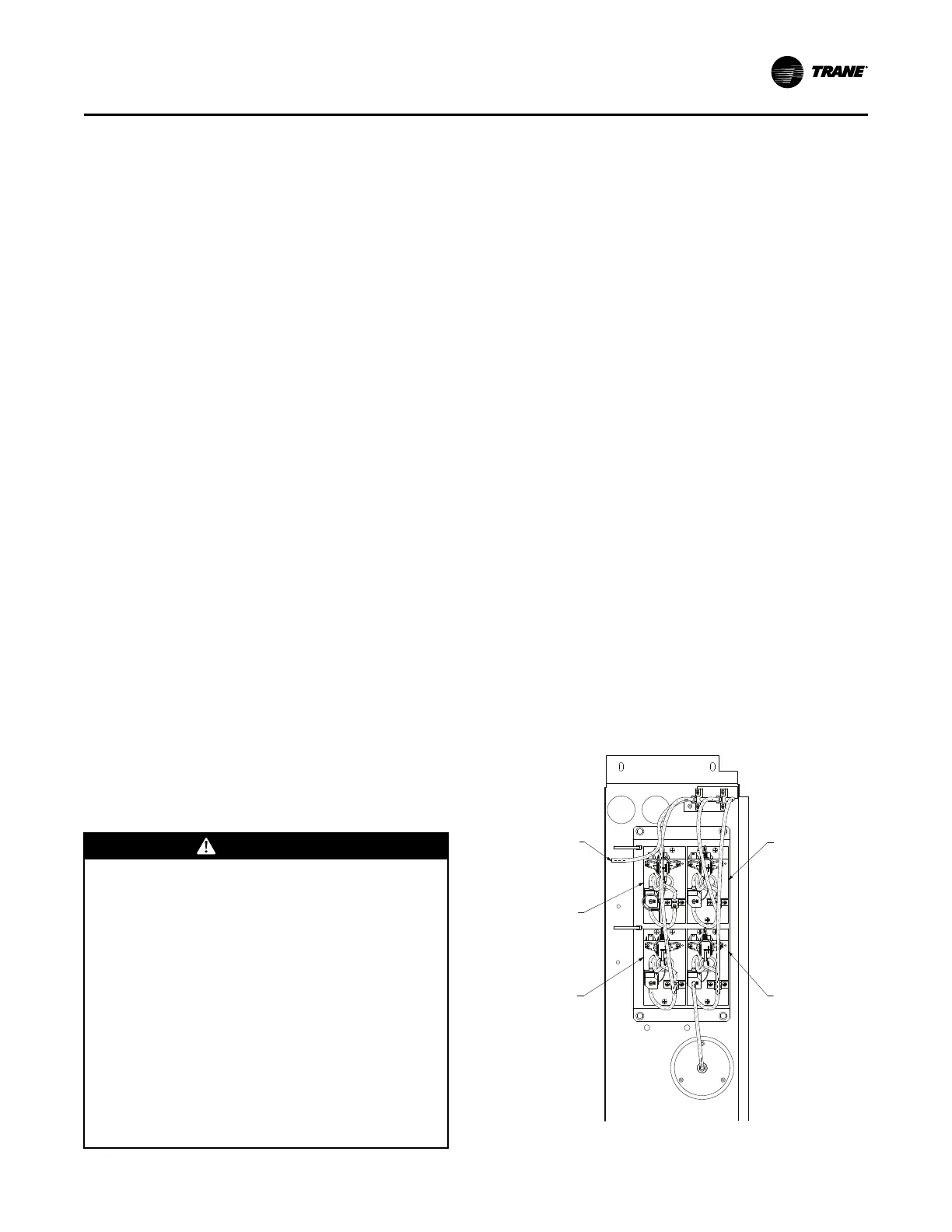

section (see Figure 33, p. 63).

Figure 33. Duct static pressure control layout

SPACE PRESSURE TRANSDUCER

& SOLENOID ASSEMBLY

DUCT STATIC

TRANSDUCER ASSEMBLY

OUTSIDE AIR REFERENCE

TUBE CONNECTS HERE

RETURN AIR TRANSDUCER

& SOLENOID ASSEMBLY

TRAQ TRANSDUCER

& SOLENOID ASSEMBLY

UUnniitt RReeppllaacceemmeenntt

Loading...

Loading...