CDJ300 & CDJ600

-18--18-

A4

A3

A1

A2

B4

B3

B1

B2

A4

A3

A1

A2

B4

B3

B1

B2

TIMBER

PREPARATION

It is important to plan

your work before starting

to save set-up time and

avoid costly mistakes.

Both sides of the jig can

be used to make joints. It

is advisable however to

clamp the workpiece to

one side of the jig. This

ensures it is clamped

securely.

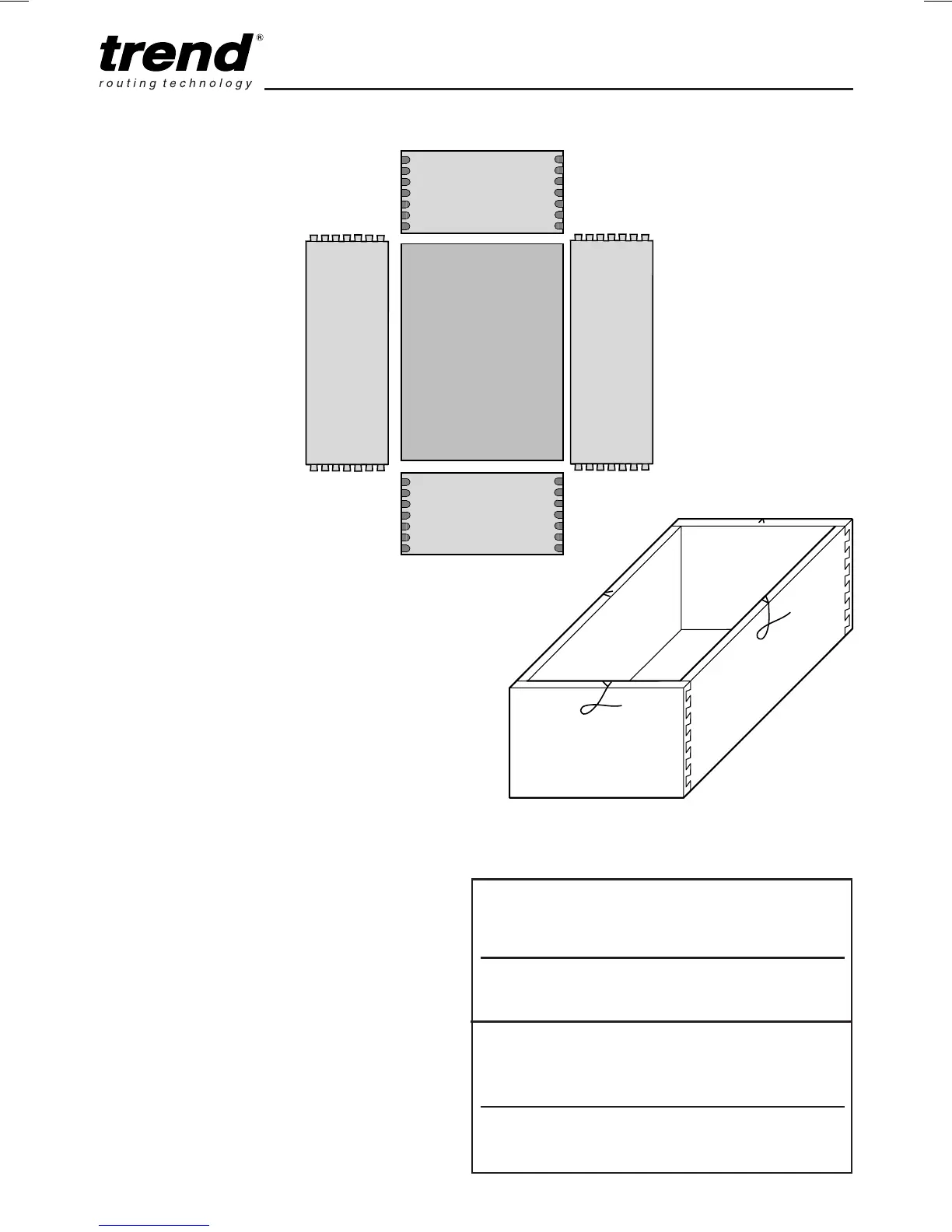

Lapped Dovetails

When lapped dovetailing

label the pieces as front,

back, and sides. Mark

faces as inside and out.

Label the dovetail pieces

as shown, A parts will

be clamped under front

clamp bar, B pieces under

top clamping bar. Even

numbers against left-hand

edge guide odd numbers

under right hand edge

guides.

Face sides must be

towards jig body.

For drawers the front is

thicker than the sides.

Before jointing the actual

workpiece make trial cuts

in pieces of waste timber,

the same thickness as

the workpieces in order to

test depth of pin sockets.

Ensure all pieces are cut

to size and checked for

squareness.

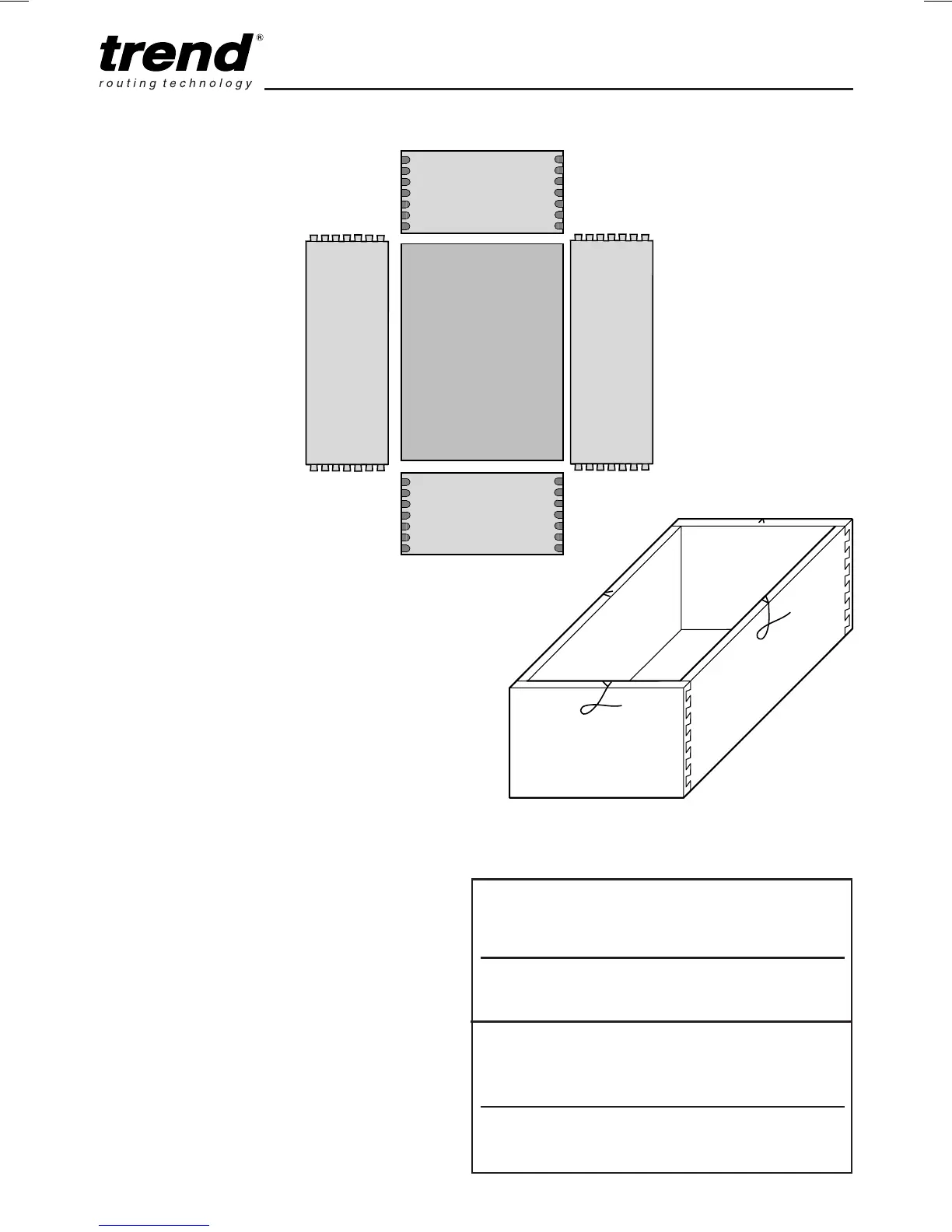

1

/2” (12.7mm) Lapped Dovetail Template

(21.5 mm pitch with 3mm offset line)

No. of whole tails

1 2 3 4 5 6 7 8 9...

21.5 43 64.5 86 107.5 129 150.5 172 193.5

Optimum width of timber in mm

ie Pitch x No. of tails = Width (when 3mm offset line used).

1

/4” (6.35mm) Lapped Dovetail Template

(11.3 mm pitch with 2mm offset line)

No. of whole tails

1 2 3 4 5 6 7 8 9

11.3 22.6 33.9 45.2 56.5 67.8 79.1 90.4 101.7

Optimum width of timber in mm

ie Pitch x No. of tails = Width (when 2mm offset line used).

Loading...

Loading...