CDJ300 & CDJ600

-19-

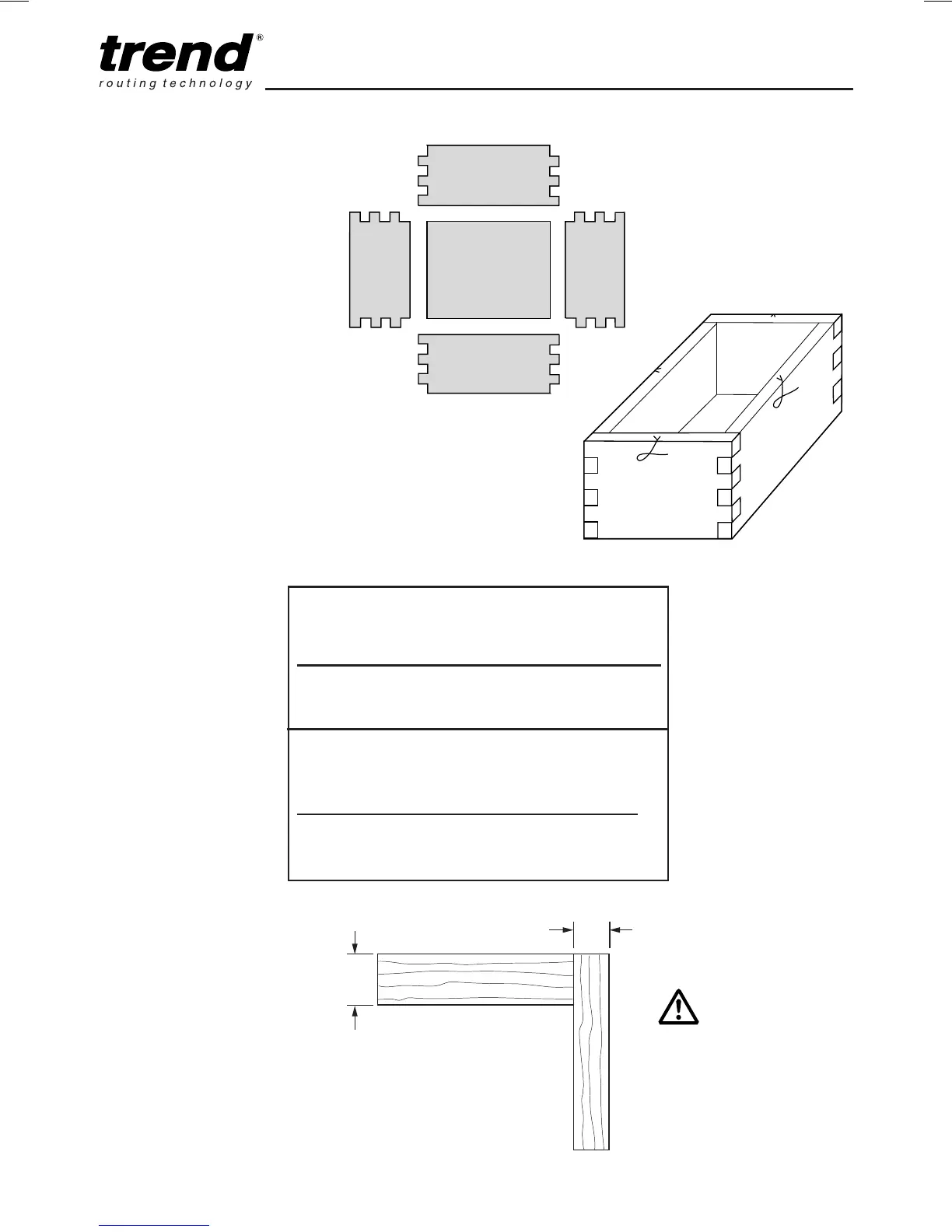

B4

B3

B1

B2

A4

A3

A1

A2

A4

A3

B1

B4

A1

A2

B2 B3

Cut all four pieces for

the box to the exact

dimensions of the final

unit.

Make sure ends are

perfectly square and exact

widths.

The workpieces are

clamped together for the

cut. Ensure the workpiece

face sides are towards the

front of the jig.

Before joining the actual

workpiece make a trial cut

in waste scrap timber.

Box Joint Waste

Piece

For box joints, the waste

piece must be 5mm thicker

than the work piece. It

should be long enough to

be held securely by the

clamp bars.

The width should be at

least 5mm wider than

work piece. The waste

piece reduces likelihood of

breakout.

8mm Comb Template

(16mm pitch with symmetrical sockets)

No. of sockets

1 2 3 4 5 6 7 8 9...

24 40 56 72 8 104 120 136 152

Optimum width of timber in mm

ie Pitch x No. of sockets + 8mm = Width

1

/2” (12.7mm) Comb Template

(25.4mm pitch with Symmetrical Sockets)

No. of Sockets

1 2 3 4 5 6 7 8 9...

38.1 63.5 88.9 114.3 139.7 165.1 190.5 215.9 241.3

Optimum width of timber in mm

ie (Pitch x No. of Sockets) + 12.7mm = Width.

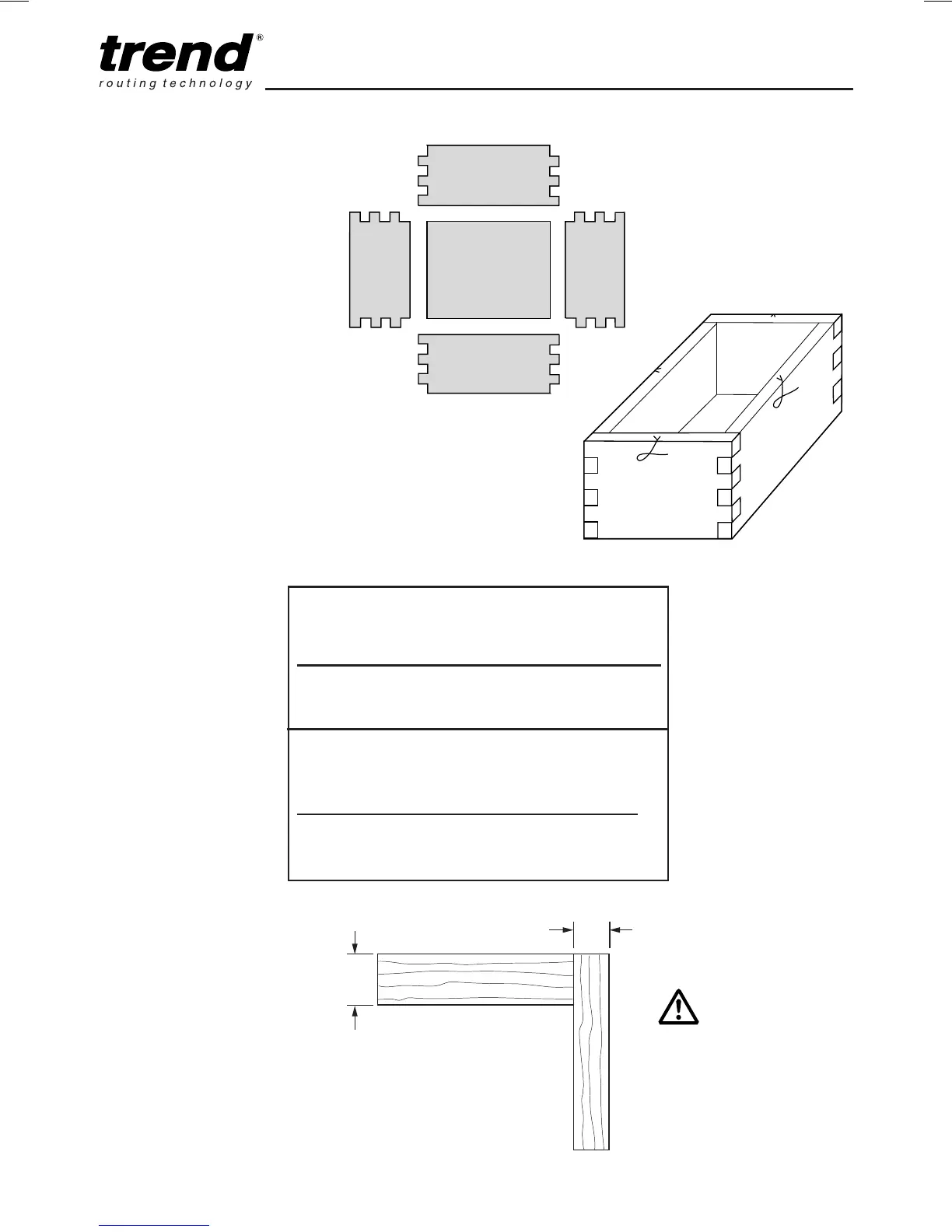

The waste piece for

box joints must be

5mm thicker than the

workpiece to prevent

the cutter touching

the jig body.

x + 5mm

x

Waste piece

Workpiece

Box Joint

(Optional Accessory)

Loading...

Loading...