27

Gas Piping

NATURAL GAS

Pipe Sizing - Natural Gas

Refer to Table 1 for schedule 40 metallic pipe

length and diameter requirements for natural

gas, based on rated PRESTIGE Solo input

(divide by 1,000 to obtain cubic feet per hour).

- Table 1 is based on Natural Gas with a spe-

cific gravity of 0.60 and a pressure drop

through the gas piping of 0.30”w.c..

- For additional gas piping sizing informa-

tion, refer to ANSI Z223.1. For Canadian

installations refer to B149.1 or B149.2.

Natural Gas Supply Pressure Requirements

1. Pressure required at the gas valve inlet

supply pressure port:

- Maximum 13”w.c. at flow or no flow

conditions to the burner.

- Minimum 5”w.c. during flow conditions

to the burner. Must be verified during

start up and with all other gas appliances

operating within the building.

2. Install 100% lockup gas pressure regulator

in the gas supply line if inlet pressure can

exceed 13”w.c at any time. Adjust the lock-

up pressure regulator for 13”w.c maximum.

DO NOT adjust or attempt to measure

gas valve outlet pressure. The gas valve

is factory-set for the correct outlet pres-

sure. This setting is suitable for natural

gas and propane and requires no field

adjustment. Attempts by the installer to

adjust or measure the gas valve outlet

pressure could result in damage to the

valve, causing potential severe personal

injury, death or substantial property

damage.

The natural gas orifice requirements are:

PRESTIGE Solo 60: 0.204” (5.2 mm)

PRESTIGE Solo 175: None Required

PRESTIGE Solo 250: None Required

PRESTIGE Solo 399: 0.339” (8.6 mm)

WARNING

NOTICE

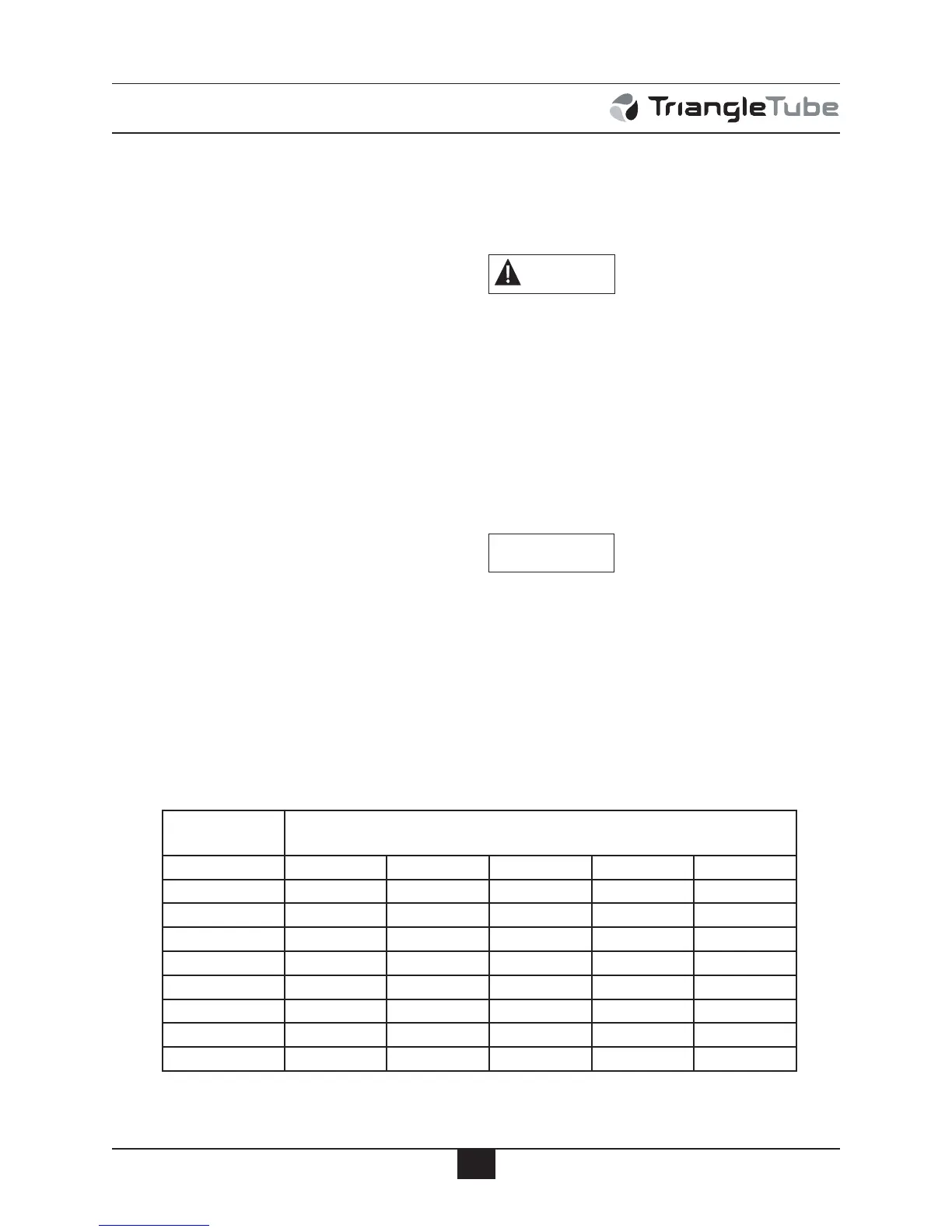

Table 1: Gas Piping Sizing - Natural Gas

Length of Pipe in

Feet

Capacity of Schedule 40 Metallic Pipe in Cubic Feet of Natural Gas Per

Hour (based on 0.60 specific gravity, 0.30" w.c. pressure drop)

SCH 40 1/2" 3/4" 1" 1-1/4" 1-1/2"

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

75 45 93 175 360 545

100 38 79 150 305 460

150 31 64 120 250 380

Loading...

Loading...