25D01-060en202008 Manual nanoFlu

UseCalibration

Commis-

sioning

Introduction

General

Information

FAQ Technical DataWarranty

Customer

Service

Contact

Keyword

Index

Accessories

Malfunction &

Maintenance

nanoFlu // Malfunction & Maintenance

6.1.3 Preparing the Sensor for the Function Test and Zero Value Determination

Clean the probe as described in chapter 6.1.1 and 6.2.2. At the end of the cleaning process, rinse the probe

carefully with deionized water. Dry the sensor with a paper towel. Wipe the sensor o with a little acetone on a

kitchen towel to remove any greasy residues.

Clean the sensor window with special optical paper or a soft, lint-free cloth and a few drops of acetone accord-

ing to the previous instructions on cleaning the measuring window.

Important: Polish the window next with a soft dry cloth or special optical paper to remove the thin lm that may

have appeared while cleaning the window.

Have a suitable measurement container lled with ultra-pure water ready nearby. Before this step, the measure-

ment container should already have been cleaned carefully with a detergent solution and rinsed with ultra-pure

water.

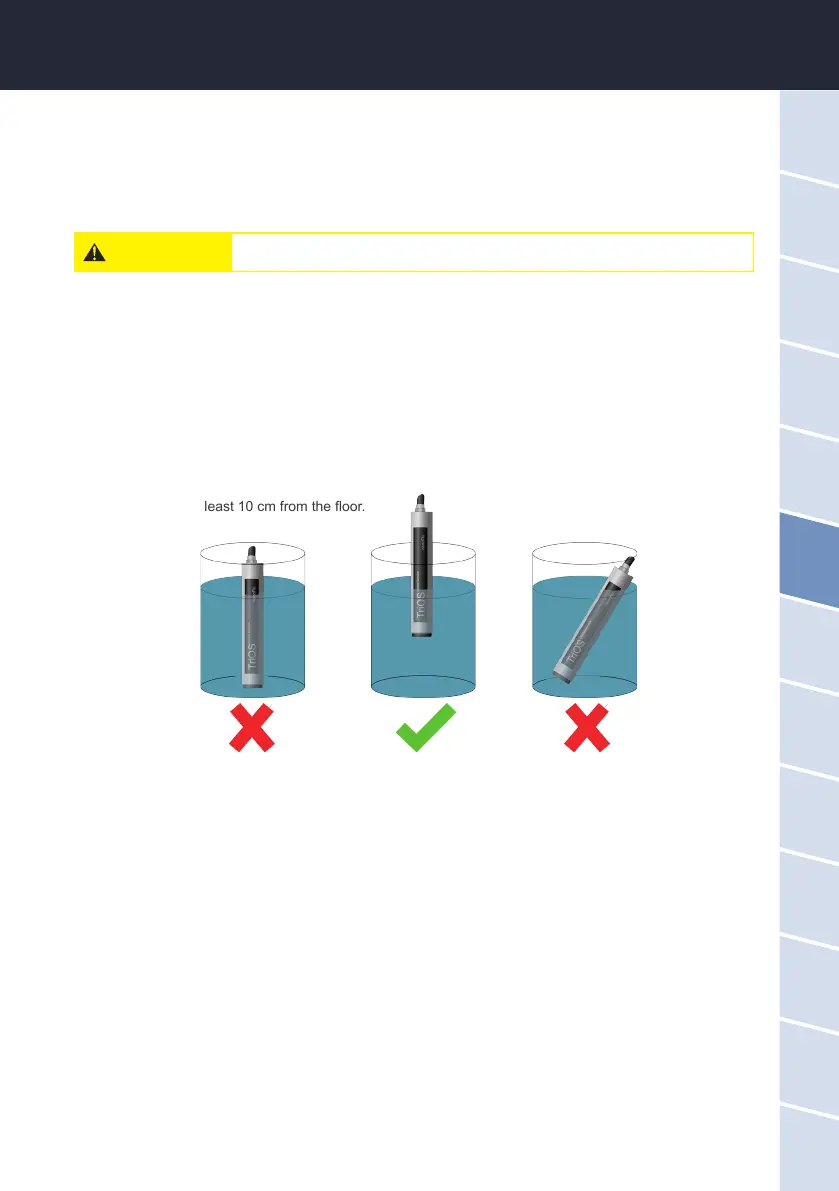

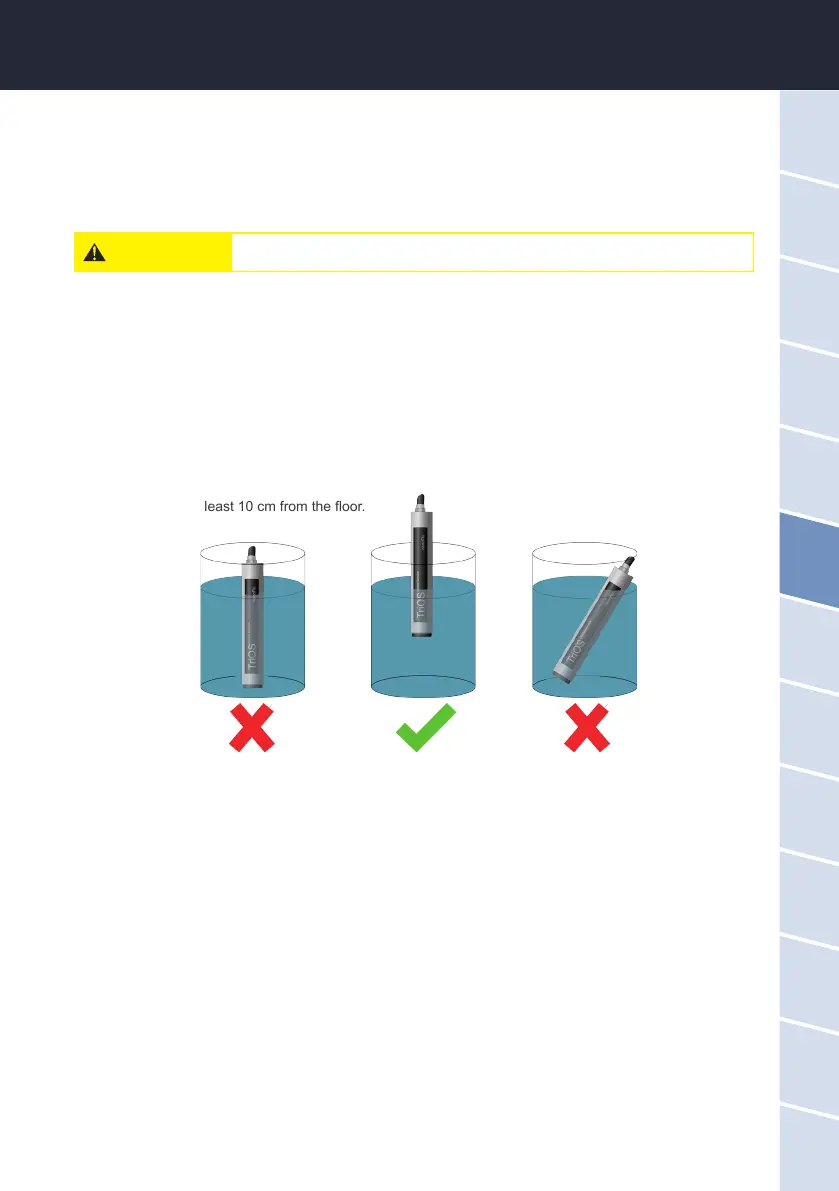

Immerse the sensor in the container, which has been suciently lled with ultra-pure water so that the measur-

ing window is completely immersed in water. Never place the sensor on the measuring window. The measuring

window should be at least 10 cm from the oor.

Wait 10 – 15 minutes. During this time, hidden dirt can come loose from the sensor.

Remove the probe from the water and rinse it with ultra-pure water. Fill the container once more with fresh

ultra-pure water and immerse the sensor again. Lift the probe and move it around in the water to remove any air

bubbles that may have formed. Carry out the function test or the calibration of the sensor.

The sensors should be positioned diagonally in the measurement container, if at all possible, to prevent very

small, almost invisible air bubbles collecting at the top of the measuring window. When using an upright meas-

uring cylinder which requires the sensor to be positioned vertically, make sure to watch out for air bubbles in

the optical path.

Make sure the measurement container is suciently stable!

For your own safety, you must wear the appropriate gloves and protective

goggles!

CAUTION

Loading...

Loading...