Bar mixers

8

Offer the shower valve to the fittings and ensuring

the sealing washers are place, screw the unions

onto the fittings.

Straight fittings

The straight connectors can be used to connect to

1/2” BSP female elbow fittings in solid wall

installations. The terminating outlet elbows must

be aligned horizontally and centred to 150mm.

The hot and cold supply pipes must be anchored

rigidly in order to support the valve and prevent

movement after installation.

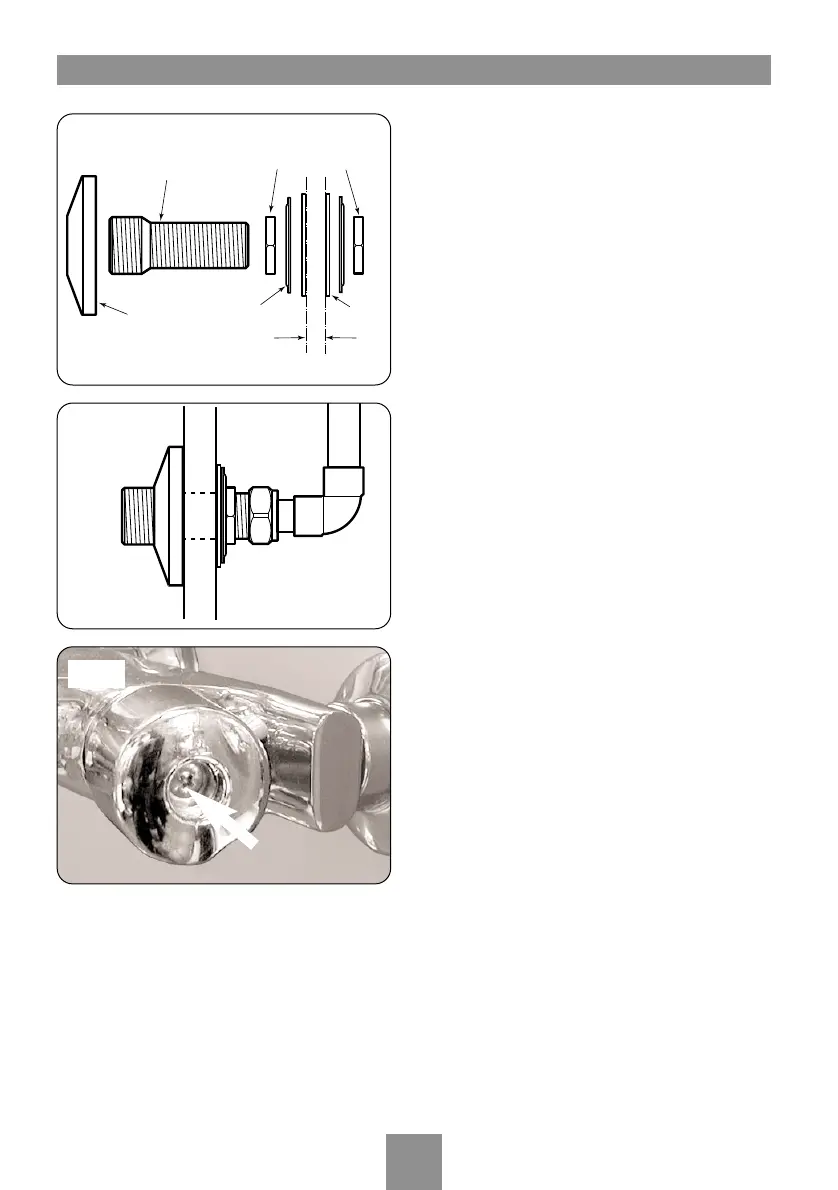

If installing in hollow walls or laminate cubicles,

the fittings are supplied to compress onto the wall

to support the shower valve (fig.10).

The maximum thickness of wall is approx. 20mm.

Sufficient room must be left on the fitting to

accommodate the compression nut and olive. At

the front end, allowance must be made to accept

the shower union and collar.

Flush out the pipework in accordance with

Water Regulations and Byelaws.

Connect 15 mm pipes using standard

compression nuts and olives (fig.11).

Screw the supplied collars onto the fittings until

tight to the wall.

Offer the shower valve to the fittings and ensuring

the sealing washers are place, screw the unions

onto the fittings. If installing with a combi

multipoint system, ensure the flow limiters are

fitted.

LEAK TESTING

Fit the hose to the outlet and direct it to waste.

Open the supplies and test for leaks in the valve

connections. Remedy any leaks if necessary.

COMMISSIONING

Ensure that both hot and cold water supplies are

fully open and at (or near to) their design

temperature and pressures and are within the

requirements as stated.

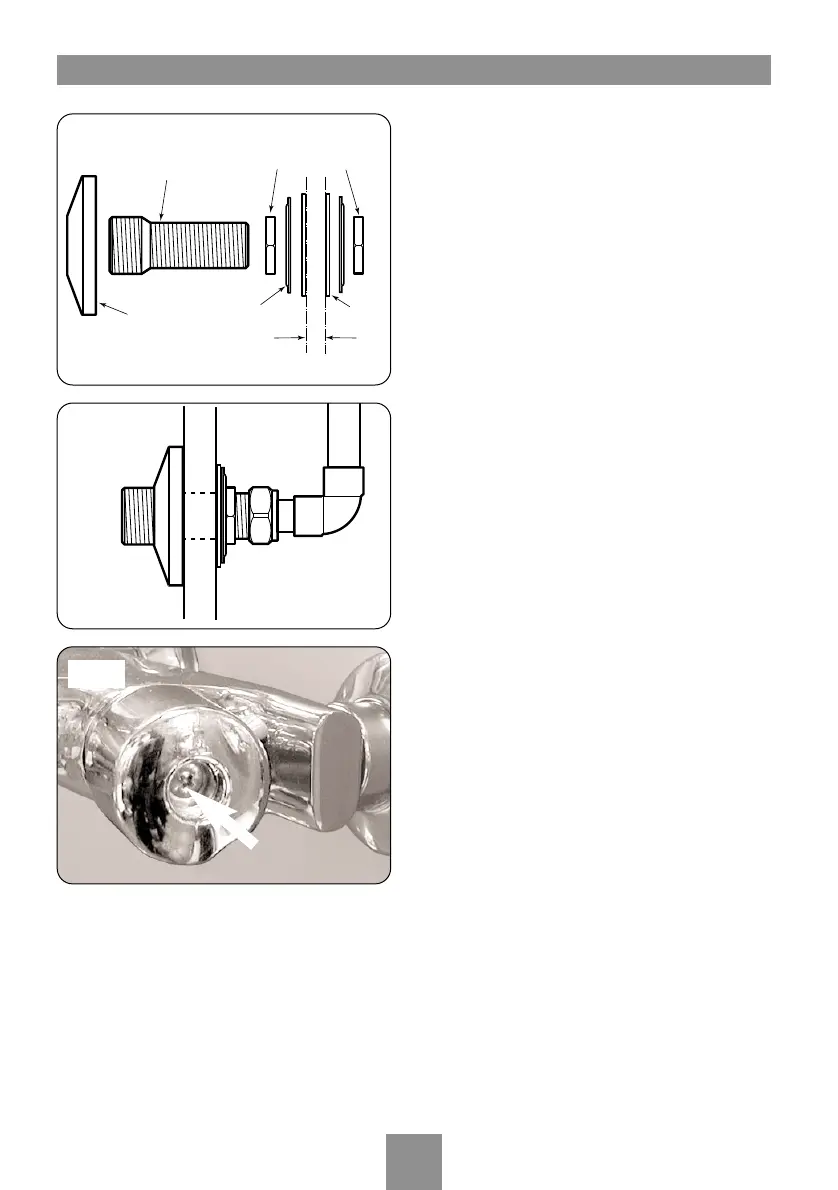

Ensure the temperature knob (right side) is

rotated fully anti-clockwise (press override button

to achieve maximum temperature setting).

Ensure the sprayhead is directed to waste.

Start the water flow by turning the flow control

(left side) anti-clockwise.

Fig.12

Loading...

Loading...