Bar mixers

INSTALLATION

NOTE: The outlet of the shower must not be

connected to anything other than the sprayhead

supplied. DO NOT use jointing compounds on

any pipe fittings for the installation. DO NOT

solder fittings within the vicinity of the mixer unit

as heat transfer can damage the seals and

thermostatic components.

NOTE: Suitable service valves (complying with

Water Regulations and Byelaws) MUST be fitted

on the hot and cold water supplies to the shower

as an independent means of isolating the water

supplies should maintenance or servicing be

necessary.

When connecting the pipework, avoid using tight

90° elbows. Swept or formed bends will ensure

optimum performance.

Offset fittings

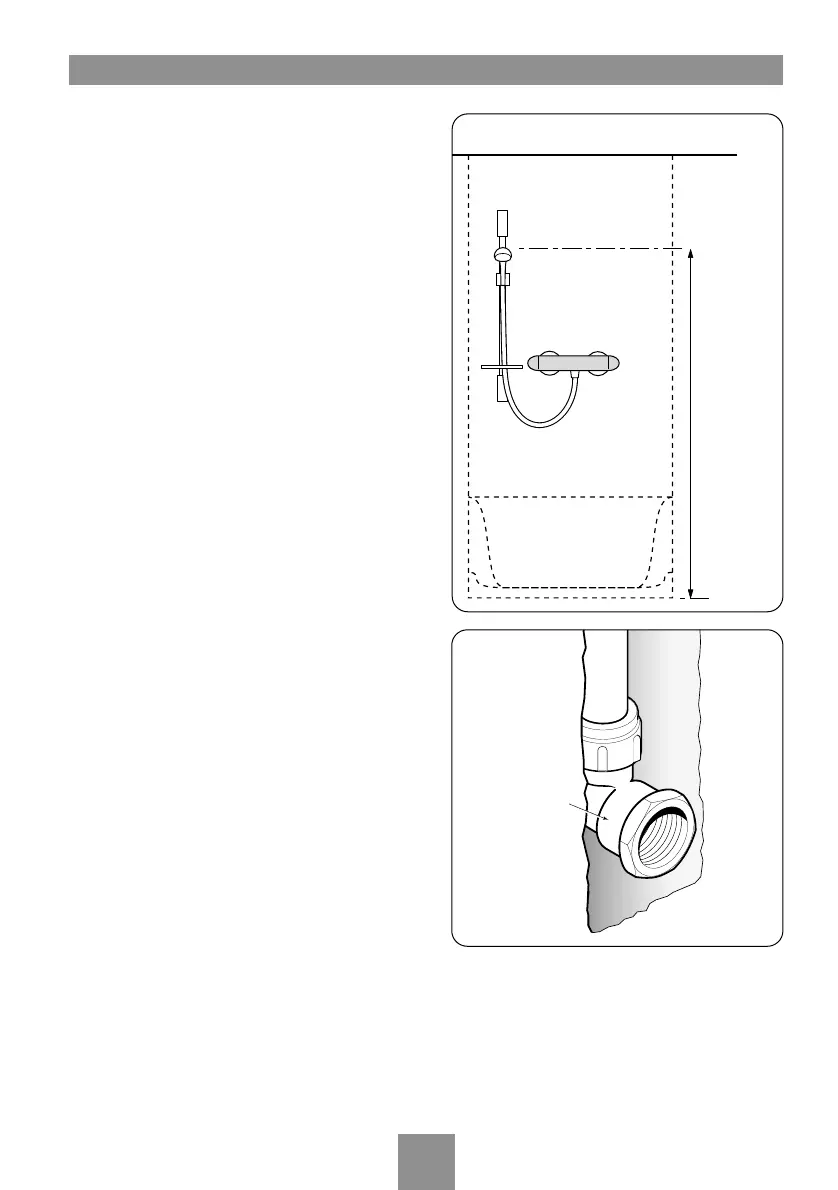

The supply pipes can be routed either from the

side, rising, rear or falling and must terminate in

standard 1/2” BSP female elbows (fig.9) to

accept the offset fittings supplied.

The inlet centres on the shower valves are 150mm

but with the offset fittings an additional 20mm

adjustment is provided.

When installing into a stud partition or other

hollow wall structures, the installer will need to

consider fabricating rear supports or other

options. Such options are beyond the scope of

this guide.

The hot and cold supply pipes must be anchored

rigidly in order to support the valve and prevent

movement after installation.

The pipe depth must be such that the face of the

elbow is flush with the finished surface.

Flush out the pipework in accordance with

Water Regulations and Byelaws.

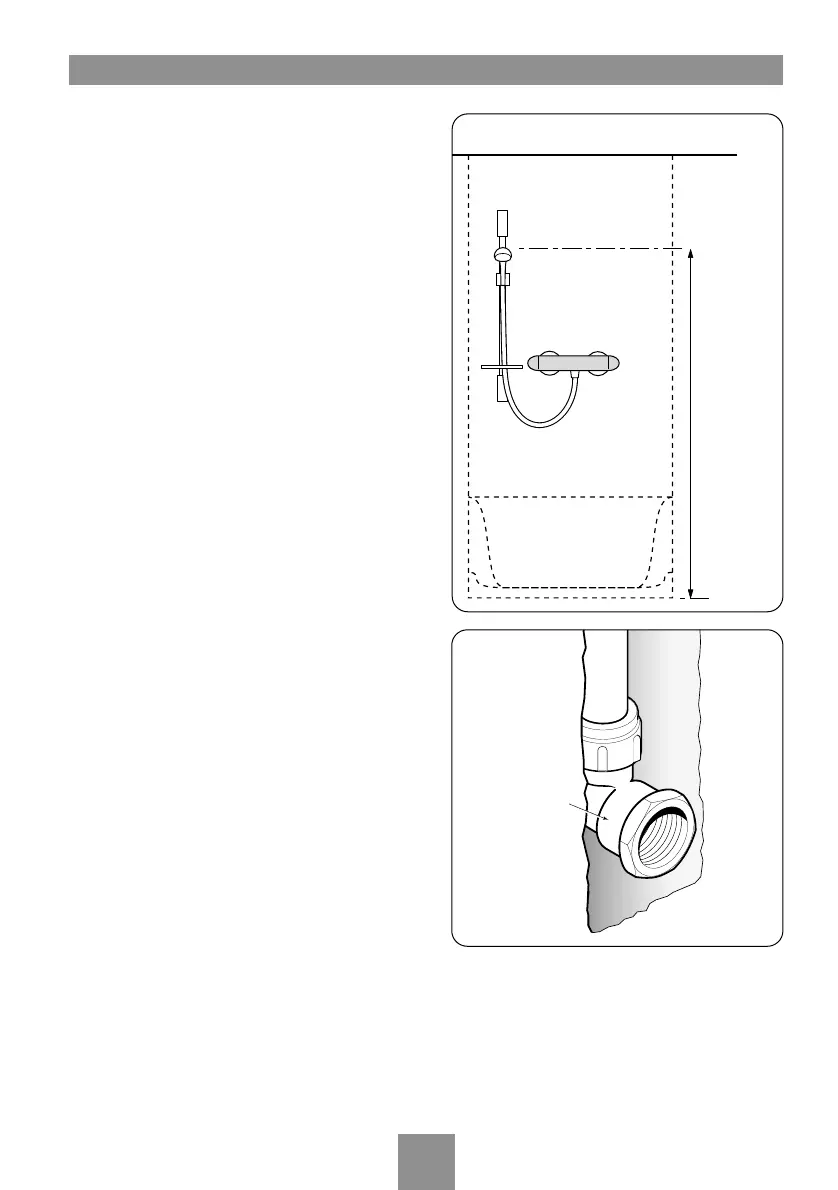

Screw the supplied offset fittings into the female

elbows using PTFE thread tape, ensuring they are

the correct centres for the shower valve.

Make good the wall, tiling etc. up to the outlets.

Screw the supplied collars onto the fittings until

tight to the wall. The collars will provide a limited

degree of tolerance and the amount of exposed

thread will depend on the accuracy of elbows set

in the wall.

Loading...

Loading...