Bar Mixer Shower

14

Cleaning

We recommend that all products are cleaned us-

ing warm, soapy water and dried with a suitable

cloth to help prevent limescale from forming.

Regularly drying your product after use will help

prevent limescale build-up and watermarks.

Do not use abrasive or aggressive chemical

cleaning products as this may affect the product

surface nish and invalidate your guarantee.

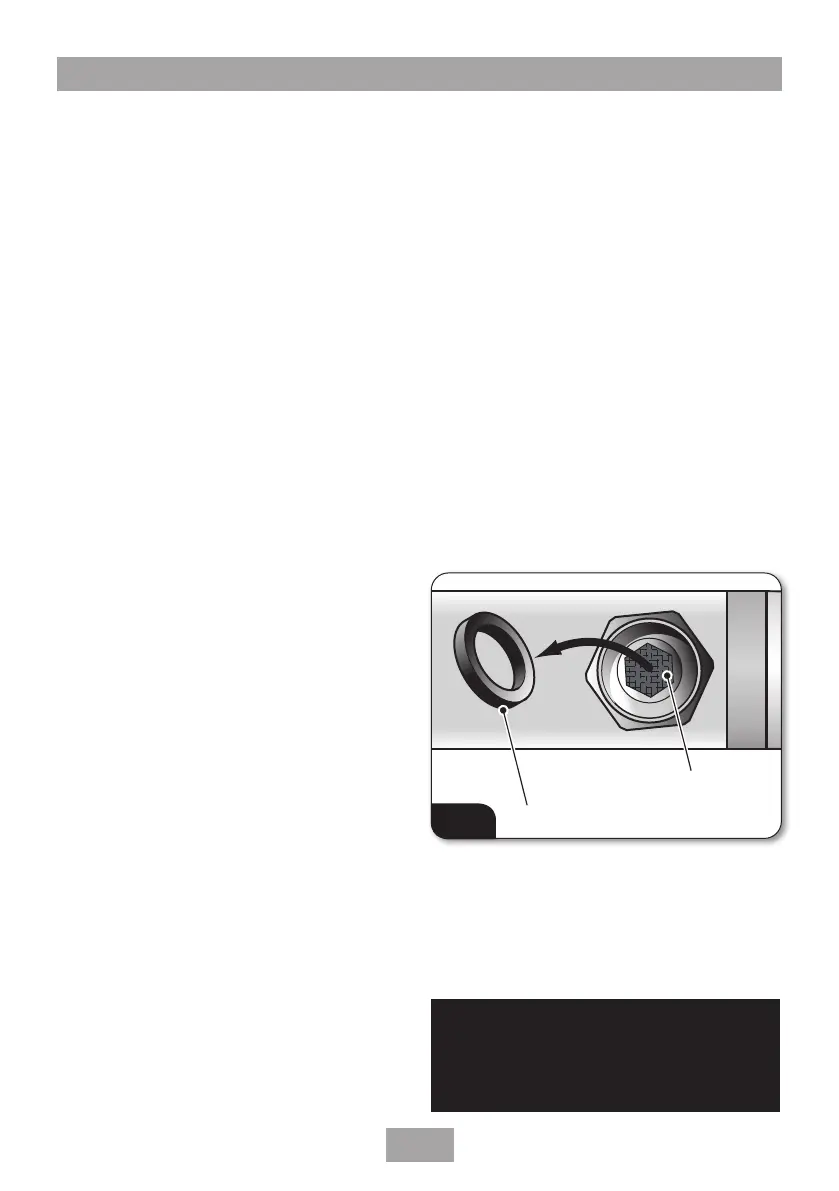

Cleaning the Filters (g.A)

It is advised that this should be carried out by a

qualified person.

Turn off the water supplies before starting.

To gain access to the lters remove the unit from

the inlet ttings.

Remove the sealing washers from the inlets.

Wash thoroughly under running water to remove

all debris using a suitable brush. Ret the sealing

washer and reassemble the shower onto the inlet

ttings.

WARNING!

DO NOT use powerful abrasive or

solvent cleaning fluids when cleaning the

shower as they may damage the fittings.

MAINTENANCE

The following maintenance procedure is

recommended for domestic installations but

must be carried out for commercial installations.

Maintenance of the unit is required to give

continued performance after installation and that

it continues to provide scald prevention.

NOTE: A thermostatic mixing valve in need of

maintenance can be undetectable in normal

use and only becomes apparent when a

disruption occurs in the hot or cold water supply

temperatures or pressures.

The frequency of routine maintenance of the

internal of the valve will depend mainly on the

water supply condition. Experience of local

conditions will dictate the intervals for inspection

and in-service testing; guidance has been

given below which can be adjusted for local

requirements.

a) Initially check the lters for debris once every

three months and clean if necessary.

b) Perform a thermal shut off test every

three months, and check the maximum

temperature setting. See the Commissioning

section for the details of this test and

readjustment of the maximum temperature

setting if required.

c) If the maximum water temperature varies

by more than 2°C from the commissioned

setting then carry out the following checks

• Check the isolating valves are fully open.

• Check the internal surface for scaling.

If the body requires descaling then it should be

removed from the pipework to carry out this

work - all rubber parts must be removed before

descaling.

• Check the function of the non-return valves

The non-return valves (NRVs) prevent cross-ow

between hot and cold supplies under unequal

pressure conditions. They are designed for long

life with no maintenance.

If these checks do not highlight the reason

for the temperature variation, then internal

components will require replacement; please

contact Customer Experience.

Disinfection

Where chlorine is used for the disinfection

of water systems all relevant guidelines and

approved codes of practice must be strictly

followed. Failure to comply with the relevant

guidelines and approved codes of practice may

invalidate your guarantee.

Fig.A

Loading...

Loading...