20

3.2 Program 2 (2 - WDry 273)

Program 2 is recommended for wrapped instruments, porous load and

other materials when the manufacturer recommends autoclaving at

temperatures of up to 273ºF with a drying stage.

Nominal parameters

♦ Sterilization temperature: 273ºF - 279ºF.

♦ Sterilization time: 8 minutes.

♦ Dry time: 20 minutes.

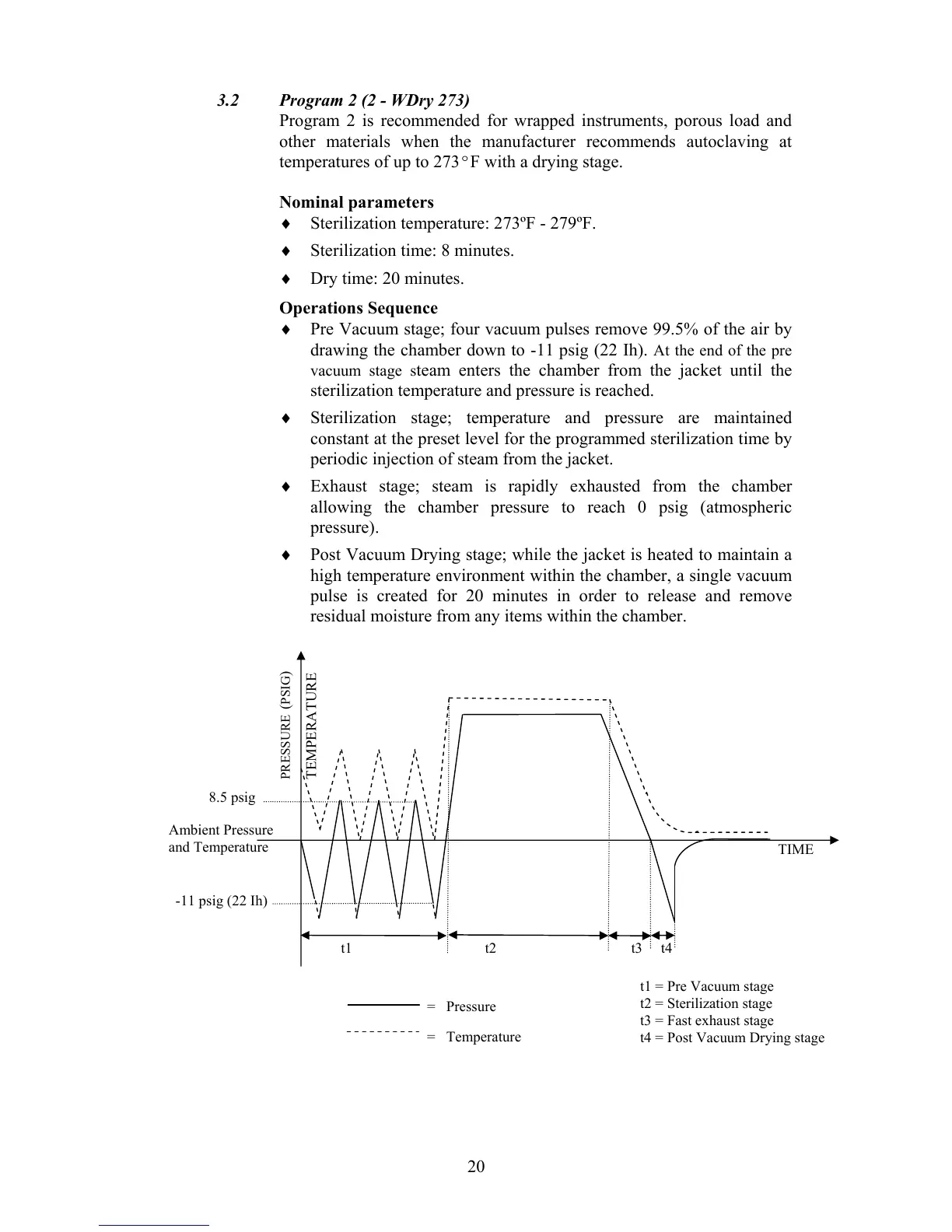

Operations Sequence

♦ Pre Vacuum stage; four vacuum pulses remove 99.5% of the air by

drawing the chamber down to -11 psig (22 Ih). At the end of the pre

vacuum stage s

team enters the chamber from the jacket until the

sterilization temperature and pressure is reached.

♦ Sterilization stage; temperature and pressure are maintained

constant at the preset level for the programmed sterilization time by

periodic injection of steam from the jacket.

♦ Exhaust stage; steam is rapidly exhausted from the chamber

allowing the chamber pressure to reach 0 psig (atmospheric

pressure).

♦ Post Vacuum Drying stage; while the jacket is heated to maintain a

high temperature environment within the chamber, a single vacuum

pulse is created for 20 minutes in order to release and remove

residual moisture from any items within the chamber.

TIME

PRESSURE (PSIG)

TEMPERATURE

Ambient Pressure

and Temperature

t1

t2

t3

-11 psig (22 Ih)

t1 = Pre Vacuum stage

t2 = Sterilization stage

t3 = Fast exhaust stage

t4 = Post Vacuum Drying stage

= Pressure

= Temperature

8.5 psig

Loading...

Loading...