YK15-0009-DI-002-04

17

3.2 Lubrication

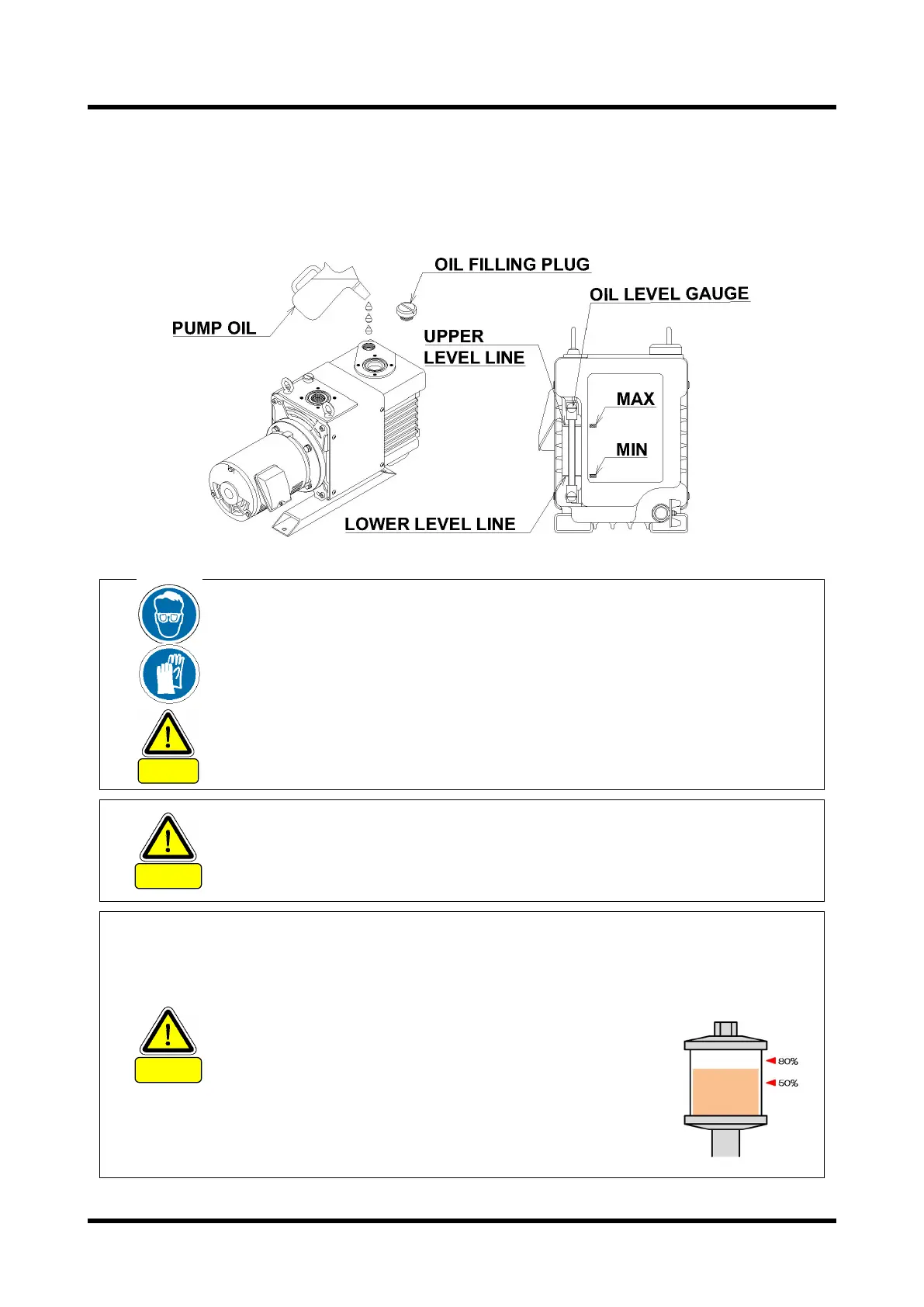

Remove oil filling plug, and fill the Pump with oil until oil level should be between the two level

lines (MAX and MIN on the Pump case) on the oil level gauge.

When the oil level is between the two level lines, the Pump is allowed to start.

Fig. 14 Lubrication and oil level indication

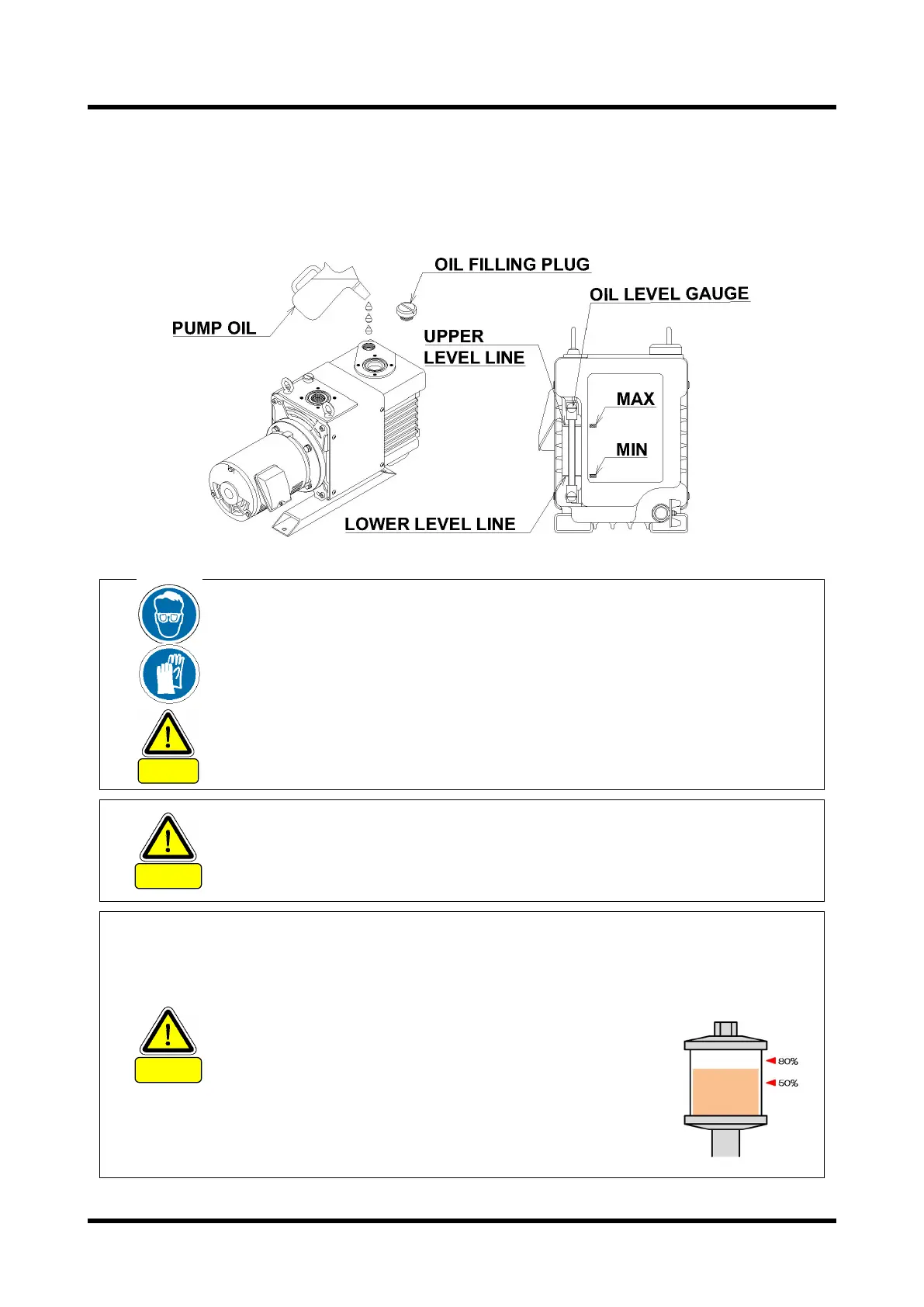

CAUTION

①

Read “1. 2 Chemical Material Safety Data Sheet” previously before

starting lubrication.

Please obtain the latest version of Safety Data

Sheet (SDS) from our Sales Department.

②

Weal protective gears such as rubber gloves, protective goggle and

so on.

Should the oil touched to your hand are entered in your eye,

immediately follow the emergency treatment described on the SDS.

CAUTION

Ensure to use the vacuum pump oil designated by ULVAC.

Operation using oil other than designated shall be out of our scope of

guarantee as it might impair the Pump

performance and shorten the life

cycle.

CAUTION

①

The oil level comes down approximately 1cm when operated the

Pump. Do not start the Pump with the minimum level oil.

② Be sure to lubricate the machine. If the

lubrication oil came down lower than limit level

during operation, it might give damage on the

bearing and shaft sealing and result in leak,

noise, motor overload and operation stop.

③ Spec.B and Spec.H pump also need oil supply

to Oiler. Fill the Oiler with oil until 50-80% of all.

Loading...

Loading...