YK15-0009-DI-002-04

33

5.2.1 Pump Oil Level Check

The Pump oil level should be between the two level lines (MAX and MIN on the Pump case) on

the oil level gauge. (Refer to Fig.14)

5.2.2 Vacuum Pump Oil Check

The Pump oil might deteriorate in a shorter time depending on the use.

If substances of low boiling point (water, organic solvent, etc.) are mixed with pump oil or sludge

collects on the bottom of the Pump case, the ultimate pressure cannot be recovered by one oil

change, but the oil must be changed several times.

If the Pump is operated using pump oil containing much moisture content, the ultimate pressure

is rise, leading to poor function of the mechanical friction parts of the Pump. In the worst case, the

Pump will seize up and cannot be rotated.

The vacuum pump oil will be gradually deteriorated not only by contamination with sucked gas,

but also by temperature rise during pump operation.

It is recommended to replace the first Pump oil within 10 days after operation start, and see how

it got contamination, viscosity and discoloring to determine the oil replacement cycle. Check and

replace the oil periodically.

CAUTION

The oil level gauge is for checking the Pump oil level. Since the oil is

not circulating between the Pump case and the oil level gauge,

contamination or discoloring of the oil may not be observed on the oil

level gauge. Periodically drain approx. 50 ml, of oil through the drain

valve and check the oil for contamination and discoloring.

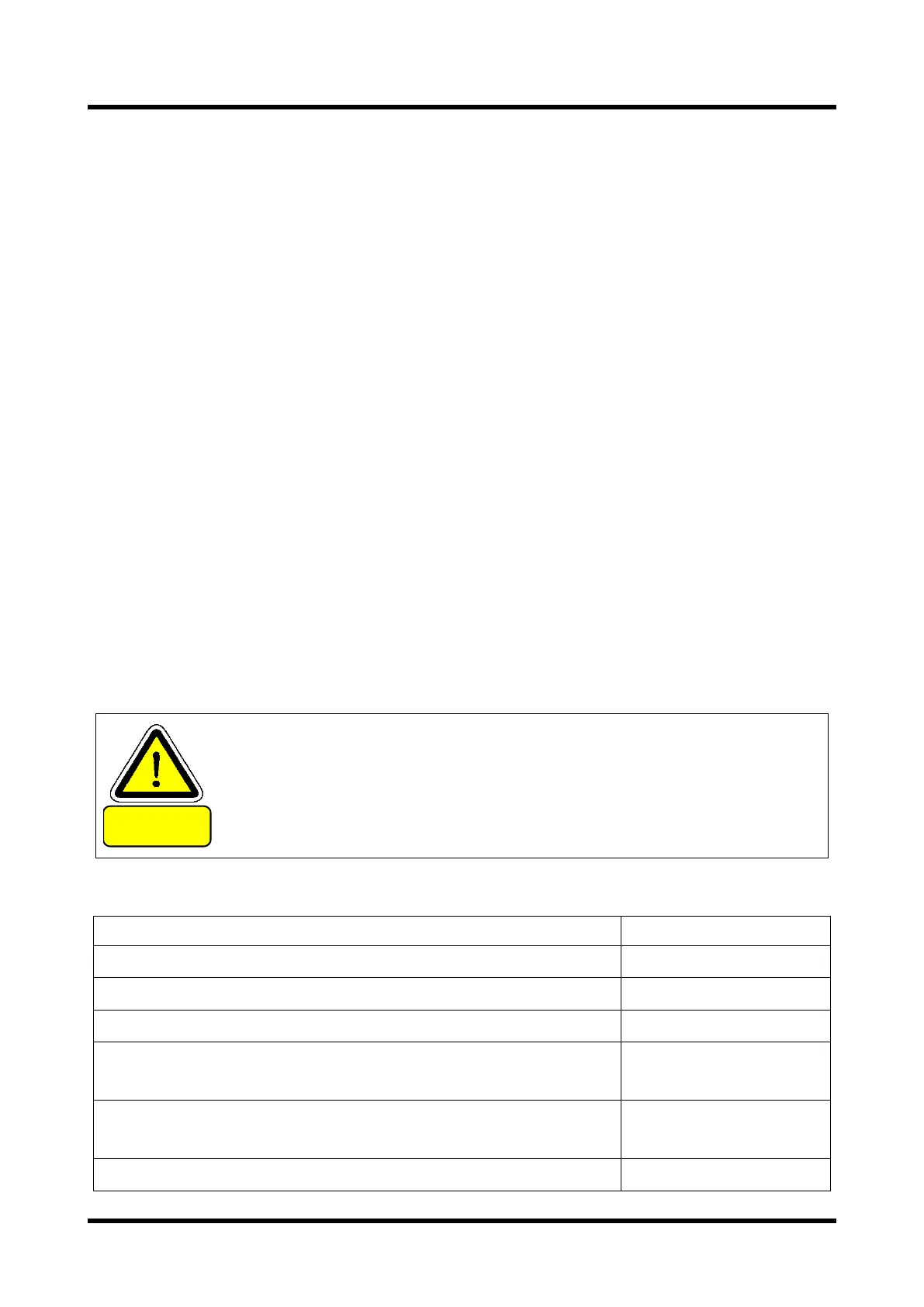

Table. 6 Recommended replacement cycle of the vacuum pump oil

Purpose Replacement timing

Vacuum system for study / laboratory, small vacuum system Within 6 months ~ 1 year

Vacuum system for production / vacuum evaporation Within 3 ~ 6 months

Vacuum valve exhaust system / large vacuum evaporation system Within 3 months

Metallurgy vacuum system such as thermal treatment, melting and

the like

Within 1 month

High vacuum dry / vacuum impregnation

vacuum formation and vacuum packing system

Within 1 month

Low vacuum dry / pug mill / food packing system Within 1 week

Loading...

Loading...