YK15-0009-DI-002-04

18

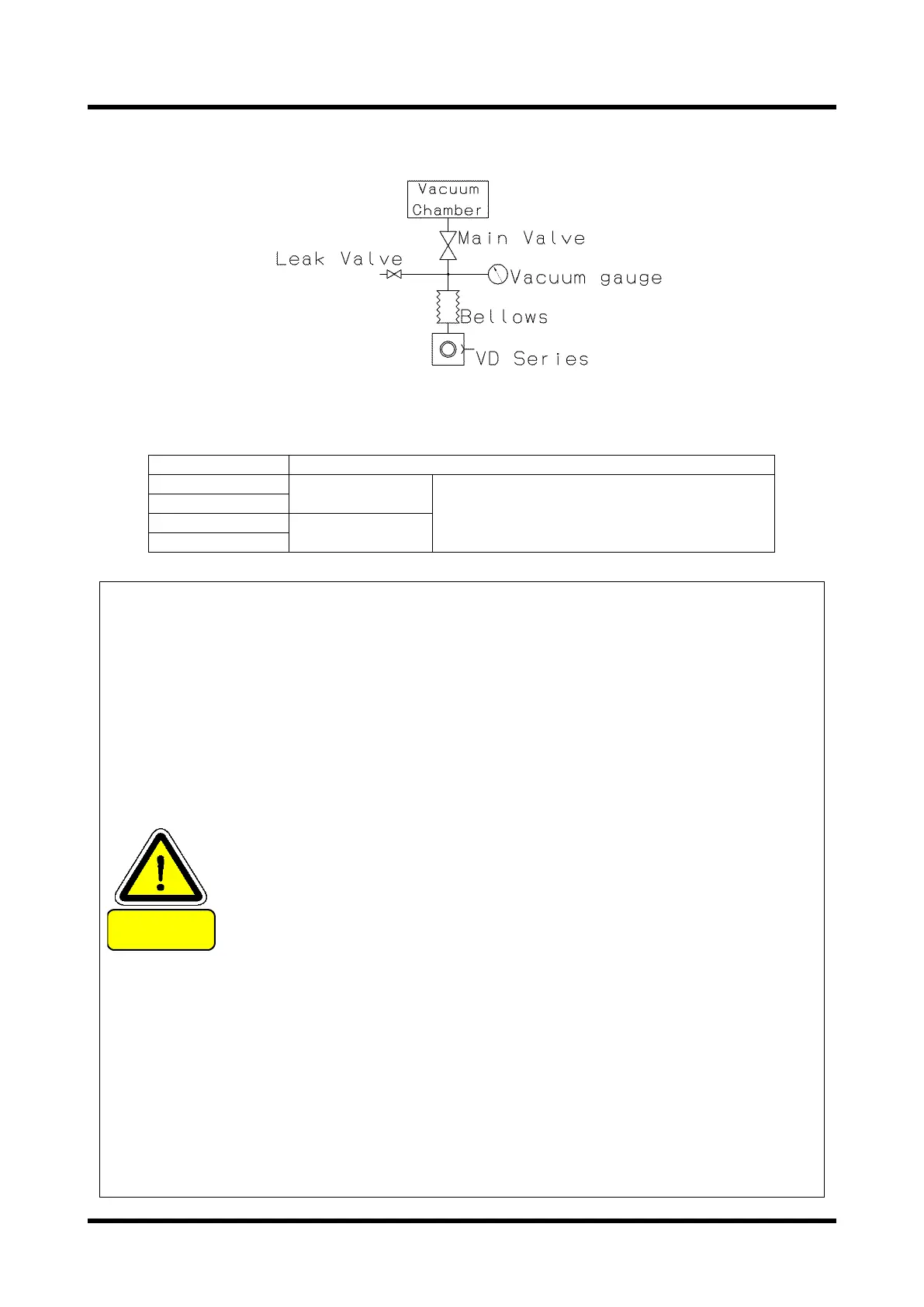

3.3 Inlet port Piping

Provide main valve, vacuum gauge and leak valve between the vacuum chamber and pump,

as shown in Fig. 15.

Fig. 15 Connection to vacuum chamber (example)

Use the flange for connection between the Pump Inlet and the piping.

VF40

JIS B 2290:1998

Vacuum technology-Flange dimensions;

Attachment book (Reference)

Flange dimensions for maintenance

VF50

CAUTION

①

Wash sufficiently inside the Vacuum chamber, pipes,

so on to connect them to the Pump. If dirty unit were connected, it

would cause a trouble such like raise the ultimate pressure or extend

the depression time to the specified pressure. Wear

to touch any vacuum section. Do not touch with the bare hand.

②

Pay a full attention to completely clear the welding scale and/or rust

inside the pipe. If obliged to conduct a welding work close to or on

the inlet, take a measure such as to remove the Pump

cover sheet on the inlet in order not to allow any foreign substance

enter inside.

③

Should the Pump sucked the water or substance such as dust,

powder and so on, it would impair the ultimate pressure and further

cause a trouble.

The Pump

has a really slight clearance to keep rotation and easily

gets impossible to rotate by any foreign substance entered inside.

④

Clear the sand completely after having sand blasted the vacuum

chamber.

⑤

Pay attention not to give damage to the Flange sheet face, Gasket

slot or gasket itself.

⑥ Metal mesh on the Suction inlet is put to keep foreign substances

away from the Pump unit.

Be sure not to take it off unless necessitated so to check it.

⑦ Use a pipe having bellows between the Vacuum chamber and in

the Mechanical Booster Pump so as to avoid any direct load to

Pump flange and not to transfer the Pump

chamber.

⑧ Put the Main valve

, Vacuum gauge and Leak valve between the

Vacuum chamber and the Pump

⑨ You should put the Leak valve closer as possible to the Main valve

order to prevent the oil from rising

up to the Vacuum chamber when

the Pump stopped.

If you use it together with the mechanical booster pump, be sure to

Loading...

Loading...