Communications vacon • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

6. COMMUNICATIONS

Features of the Modbus-Vacon interface:

• Direct control of VACON

®

drive (e.g. Run, Stop, Direction, Speed reference, Fault reset)

• Full access to all VACON

®

parameters

• Monitor VACON

®

status (e.g. Output frequency, Output current, Fault code)

6.1 Modbus address area

The Modbus interface of VACON

®

20/X uses the ID numbers of the application parameters as

addresses. The ID numbers can be found in the parameter tables described in specific Application

Manual.

When several parameters / monitoring values are read at a time, they must be consecutive.

11 addresses can be read and the addresses can be parameters or monitoring values.

NOTE: With some PLC manufacturers, the interface driver for Modbus RTU communicationmay

contain an offset of 1 (the ID number to be used would then subtract 1).

6.2 Supported Modbus Functions

The VACON

®

variables and fault codes as well as the parameters can be read and written from

Modbus. The parameter addresses are determined in the application. Every parameter and actual

value have been given an ID number in the application. The ID numbering of the parameter as well

as the parameter ranges and steps can be found in the application manual in question. The

parameter value must be given without decimals. If several parameters/actual values are read with

one message, the addresses of the parameters/actual values must be consecutive.

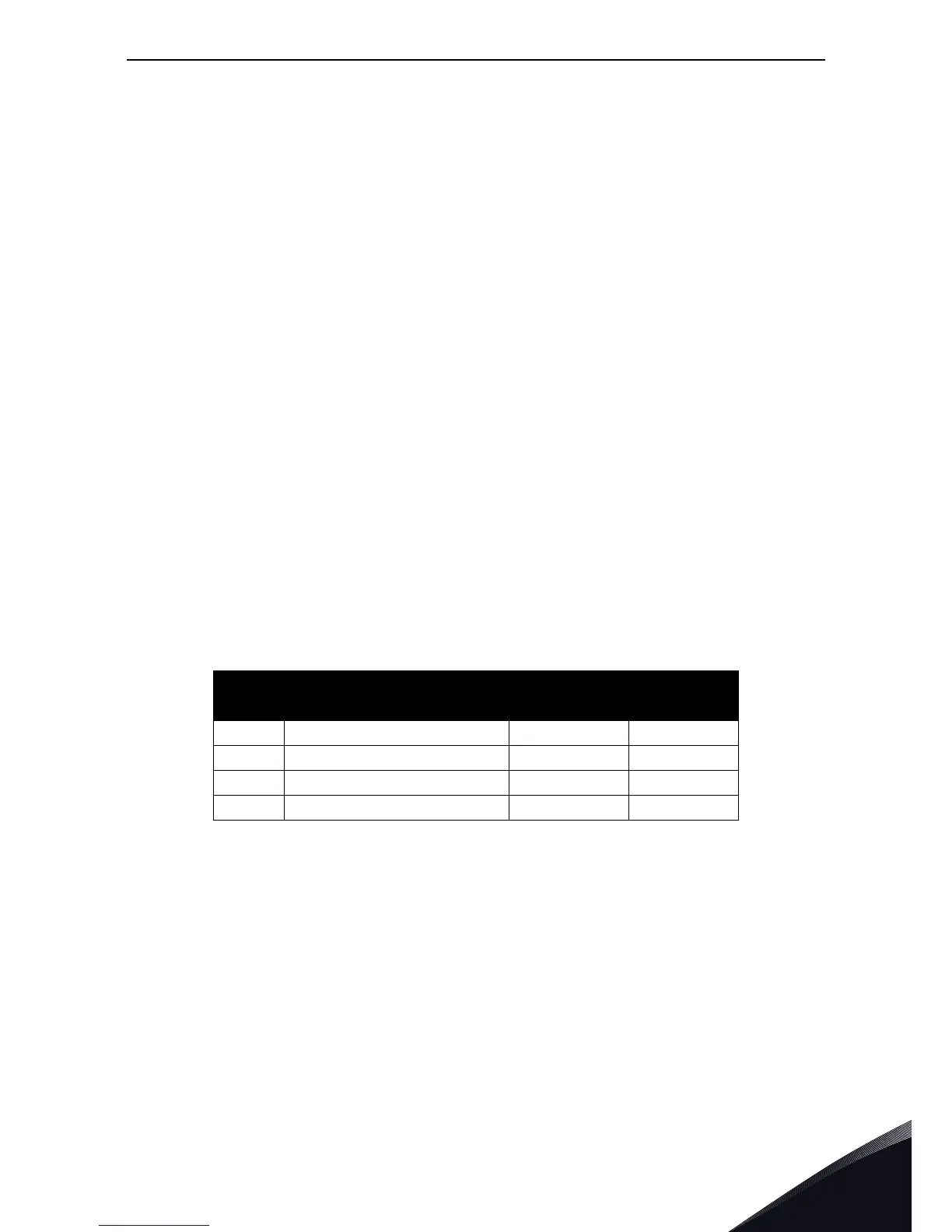

Table 7. Modbus RTU

Fun c tio n

(dec)

Function Name Address

Broadcast

messages

3 Read Holding Registers All ID numbers No

4 Read Input Registers All ID numbers No

6 Write Single Register All ID numbers Yes

16 Write Multiple Registers All ID numbers Yes

Loading...

Loading...