VACON CX Profibus user’s manual Page 12

________________________________________________________________________________________

________________________________________________________________________________________

Vacon Oyj Phone +358-201-2121 Fax: +358-201-212 205

7. PROFIBUS-VACON CX INTERFACE

Features of the Profibus-Vacon CX interface:

• Direct control of Vacon CX ( e.g. Run, Stop, Direction, Speed reference, Fault reset)

• Full access to all Vacon CX parameters

• Monitor Vacon CX status (e.g. Output frequency, Output current, Fault code ..)

7.1 General

Data transfer between Profibus DP master and slave takes place via the Input/Output data field. The

master writes to slave’s Output data and the slave answers by sending the contents of its Input data to

the master. The contents of Input /Output data is defined in a device profile, PROFIDRIVE is the device

profile for frequency converters.

The Vacon CX frequency converter can be controlled by Profibus DP master using PPO-types defined

in PROFIDRIVE (see next chapter). When fieldbus has been selected as the frequency converter’s

active control place, the frequency converter’s operation can be controlled from the Profibus DP master.

Whether or not the active control place is fieldbus, the frequency converter can be monitored and its

parameters can be set by the Profibus DP master.

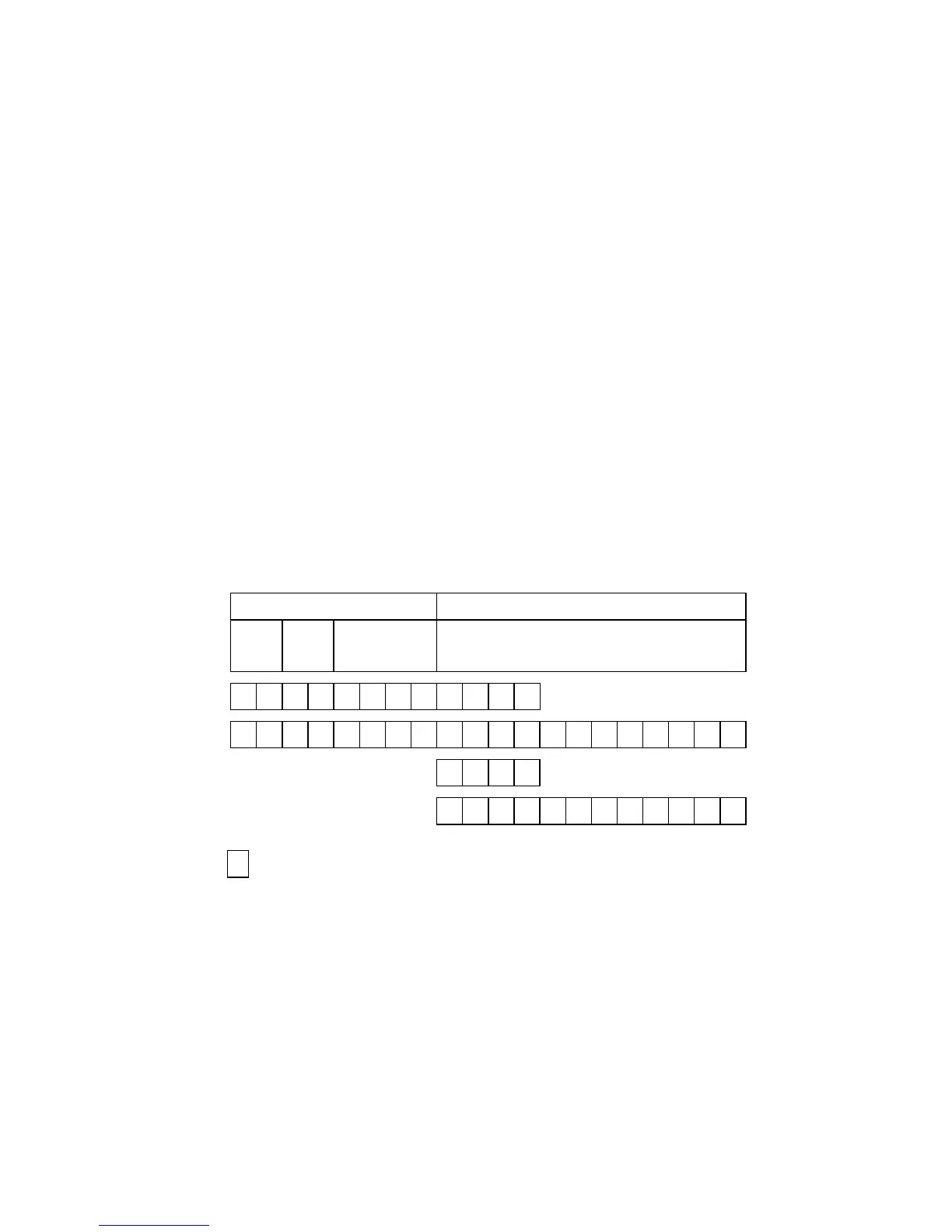

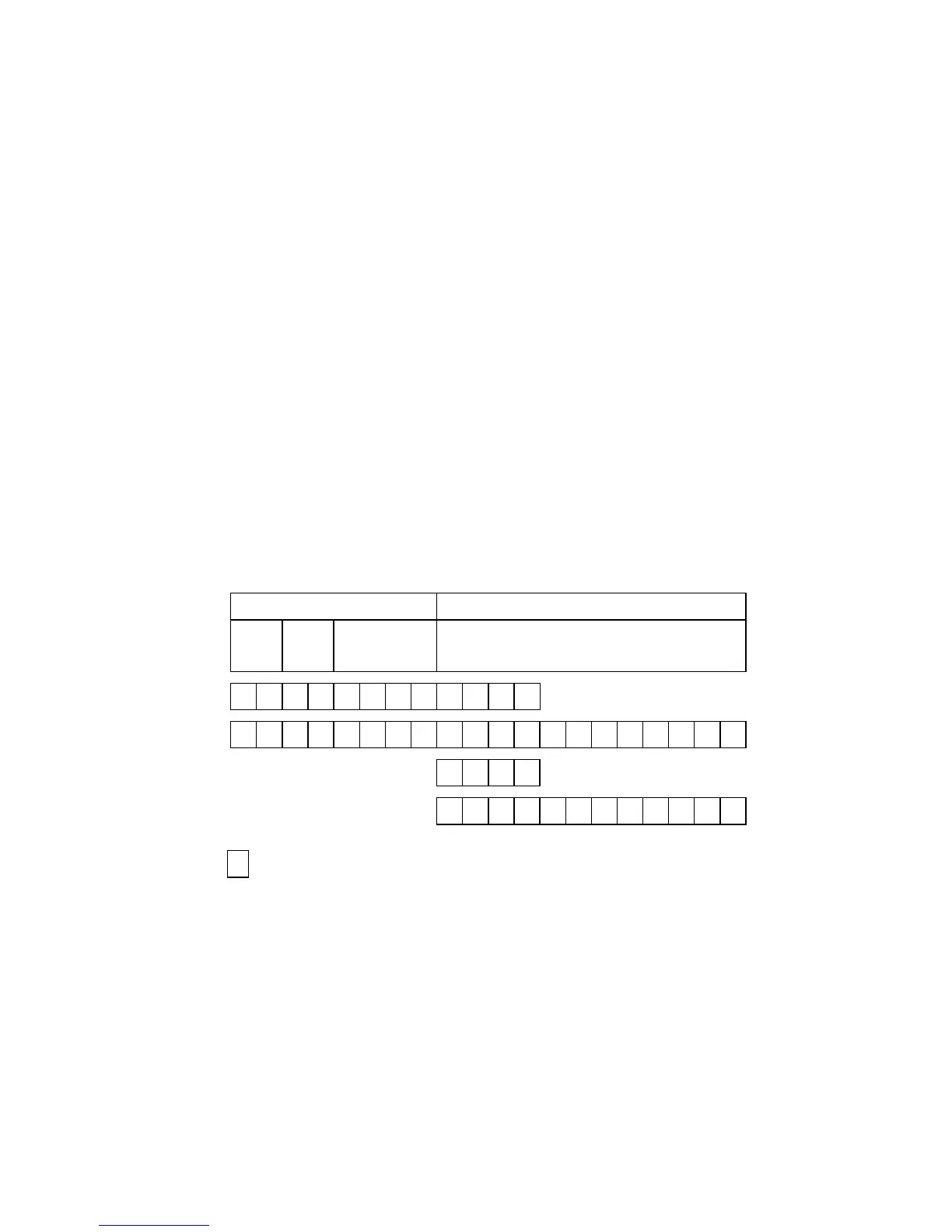

7.2 PPO-types

PPOs (Parameter/Process Data Object)are communication objects in PROFIBUS DP. PPOs in VACON

CX:

Parameter Field Process Data Field

ID IND VALUE CW

SW

REF

ACT

PD1 PD2 PD3 PD4

PPO1

PPO2

PPO3

PPO4

Byte

ID Parameter type and number

IND Parameter subindex

VALUE Parameter value

CW Control Word

SW Status Word

REF Reference Value

ACT Actual Value

PD Process Data

Loading...

Loading...