Hydraulics installation

36 Installation instructions geoTHERM 0020051574_04

5

b

Caution!

Risk of malfunction!

Dirt filters may lead to flow rate problems

and a reduction in the residual pump head

for the brine pump.

> Do not install dirt filters for a prolonged

period in the brine circuit. The brine fluid

is cleaned during the filling process.

b

Caution!

Risk of damage caused by the formation

of condensation.

Condensation on uninsulated brine pipe-

lines within the building may lead to struc-

tural damage.

> You must insulate all brine pipelines

using vapour diffusion-tight insulation.

> Fit the brine pipelines between the heat source and the

heat pump along with all the associated components in

accordance with the applicable technical guidelines.

i

To prevent freezing, use cold pipe clips to con-

nect the brine pipelines to the heat pump.

> Connect the brine pipelines to the heat pump (3) and (4)

(¬Fig.5.8).

> Insulate all pipelines using vapour diffusion-tight insula-

tion.

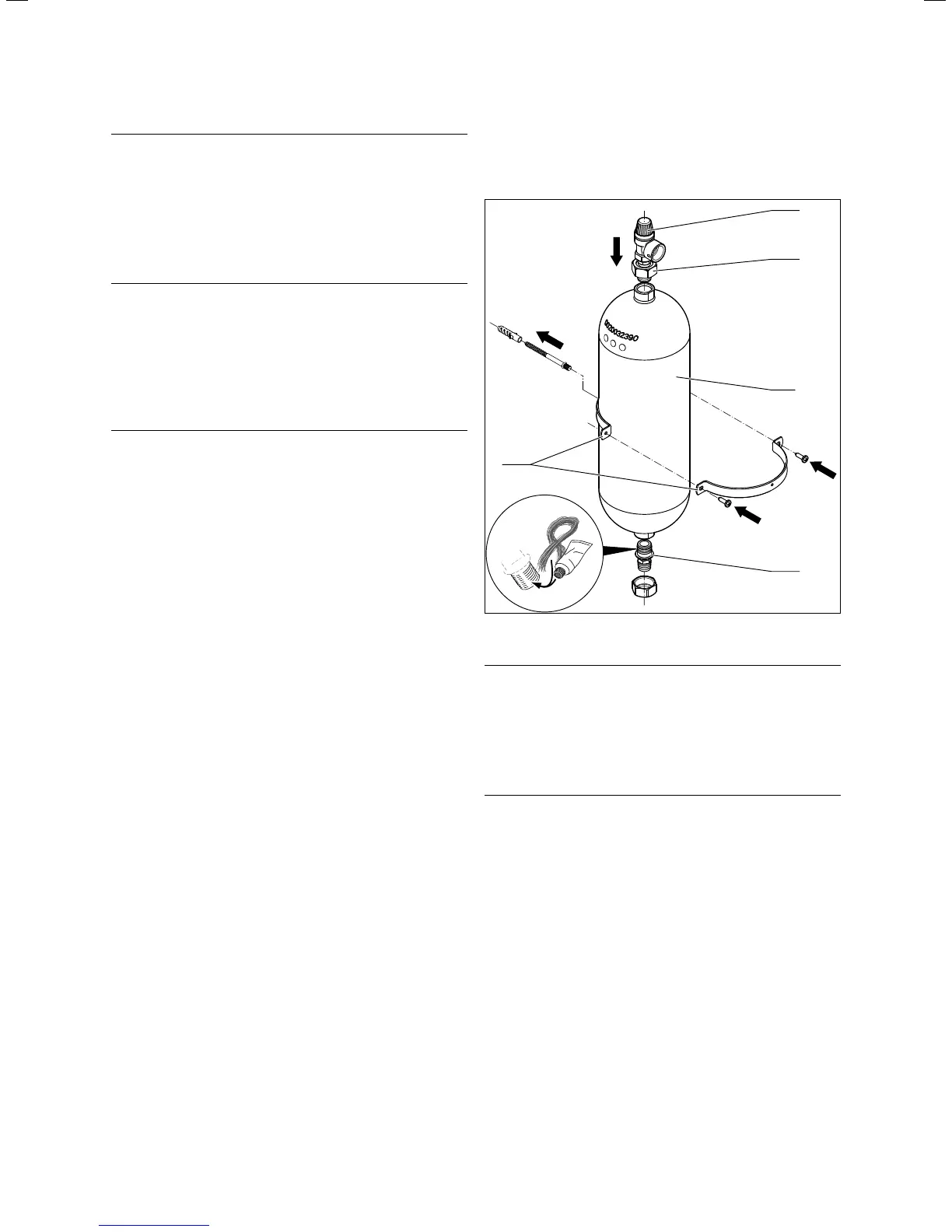

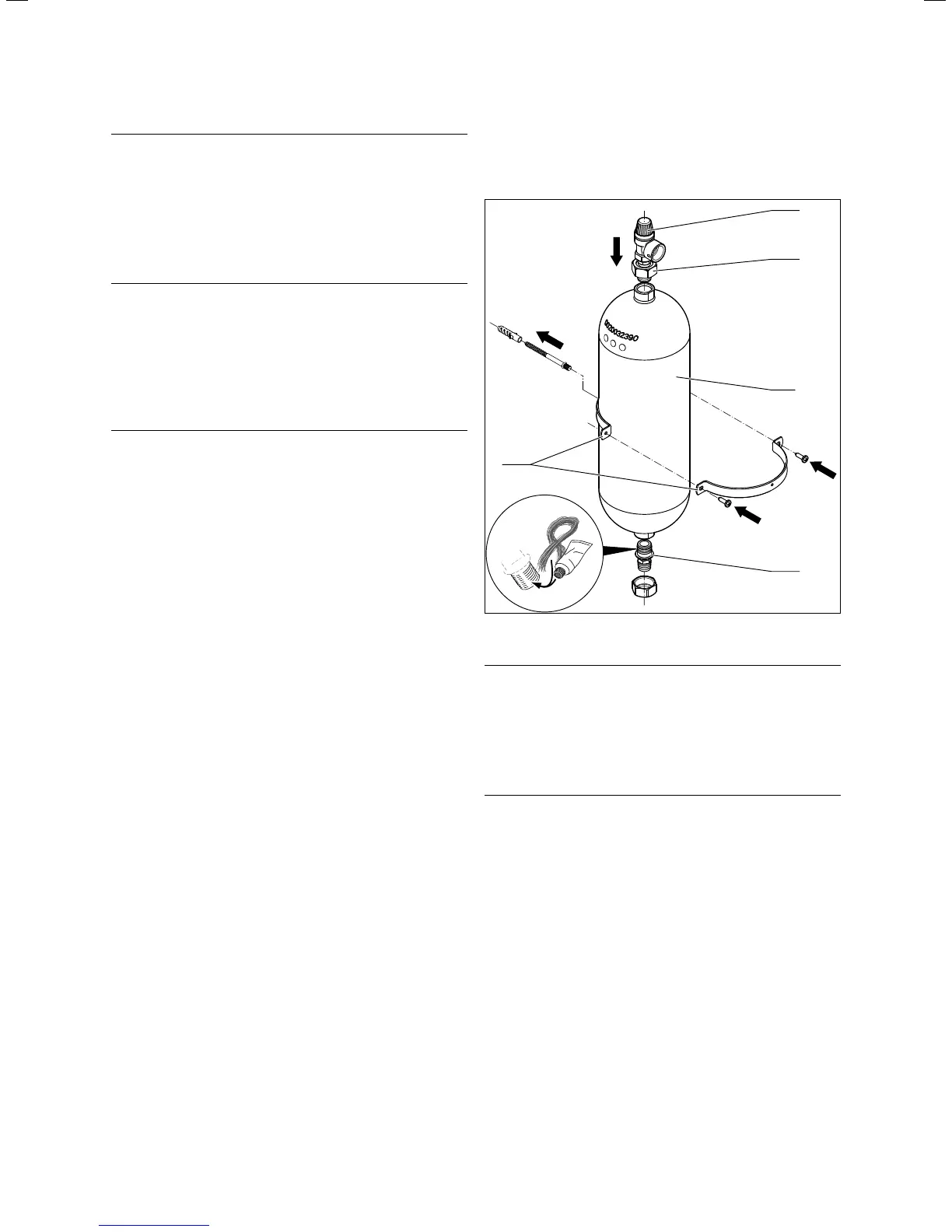

5.9 Fitting the brine expansion tank in the

brine circuit (VWS only)

42a

1

2

57

3

5.10 Fitting the brine expansion tank

b

Caution!

Risk of damage from escaping brine.

If the lower screw coupling on the brine

expansion tank (2) has been sealed using

Teflon tape or something similar, this may

lead to leaks in the brine circuit.

> Seal this screw coupling with hemp.

i

The brine expansion tank from the accessories

has a volume of approx. 6 litres and is therefore

adequate for brine circuits up to a maximum of

500 litres. For larger volumes, other expansion

tanks that are fitted on-site must be installed.

> Use the dowel and the screw to fit the bracket (3) for the

expansion tank to the wall.

> Unscrew the prefitted connecting pieces (1 and 2) from

the brine expansion tank (57).

> Put hemp on the outside thread of the lower connecting

piece.

> Install the brine expansion tank with the lower connect-

ing piece in the pipeline from the heat source to the heat

pump.

Loading...

Loading...