structure above is secure and safe.

Make the opening below the lintel by removing the masonry and clearing debris. If

the cavity has loose fill (e.g. granular) insulation material, pack the edges of the

opening with Rockwool as you proceed to hold back the insulating material.

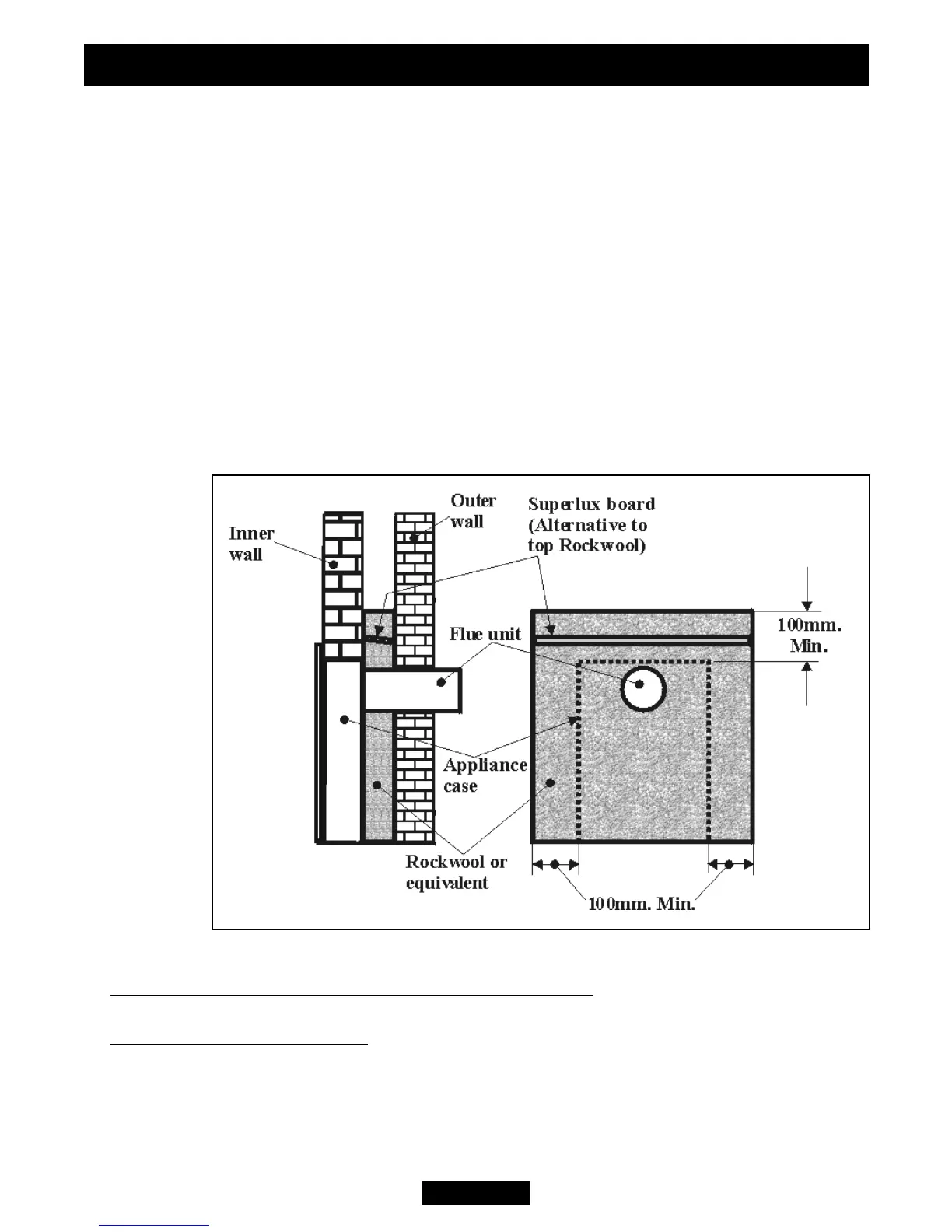

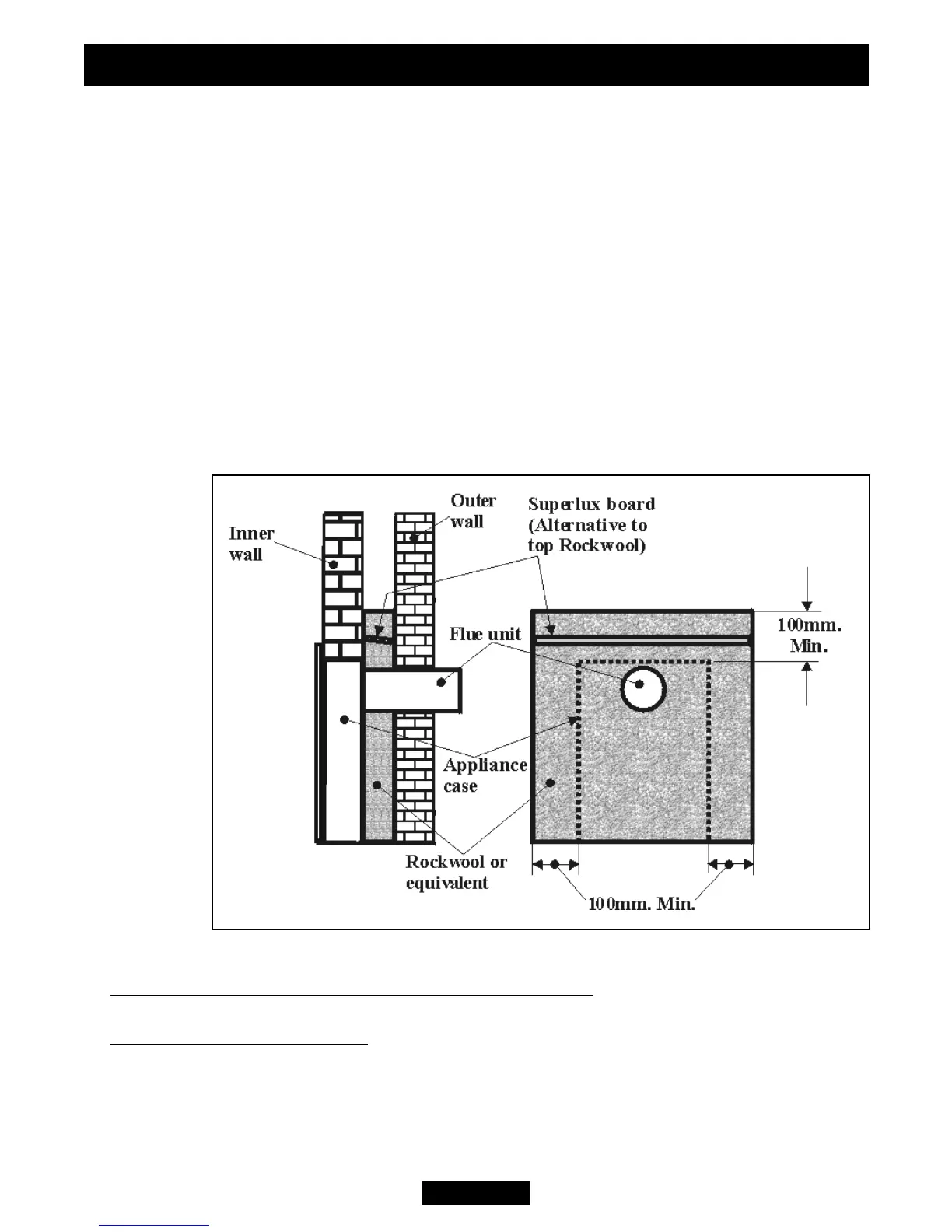

8.2.2 Preparing a wall cavity.

The wall cavity must not be bridged other than by the flue unit. The appliance case

must not project into the cavity between the inner and outer walls by more than

10mm.

The cavity should be sealed where the opening has been cut. We recommend

filling fully across the cavity with Rockwool or equivalent to at least 100mm above and

each side of the recess opening (See figure 11).

An alternative to rockwool above the opening is to seal across the top of the cavity

with Superlux board or equivalent. The board should slope downward to the back so

that any moisture will be channeled to the outside (See figure 11).

8.3 Combustible wall materials.

For brick or other non-combustible wall constructions, be sure to remove any

combustible wall cladding material from the area shown in figure 3.

For Timber frame buildings, the back surface of the appliance case must be

separated from the timber frame by 25mm of non-combustible material. This can

consist of the usual 12.5mm thick plasterboard plus a 12.5mm thick sheet of non-

combustible insulating material (e.g. fibre cement board). The insulating sheet can be

used to seal the annular gap between the flue unit and the inner leaf sleeve (See

INSTALLER GUIDE

Page 22

© Baxi Heating U.K. Limited 2010.

Figure 11.

Loading...

Loading...