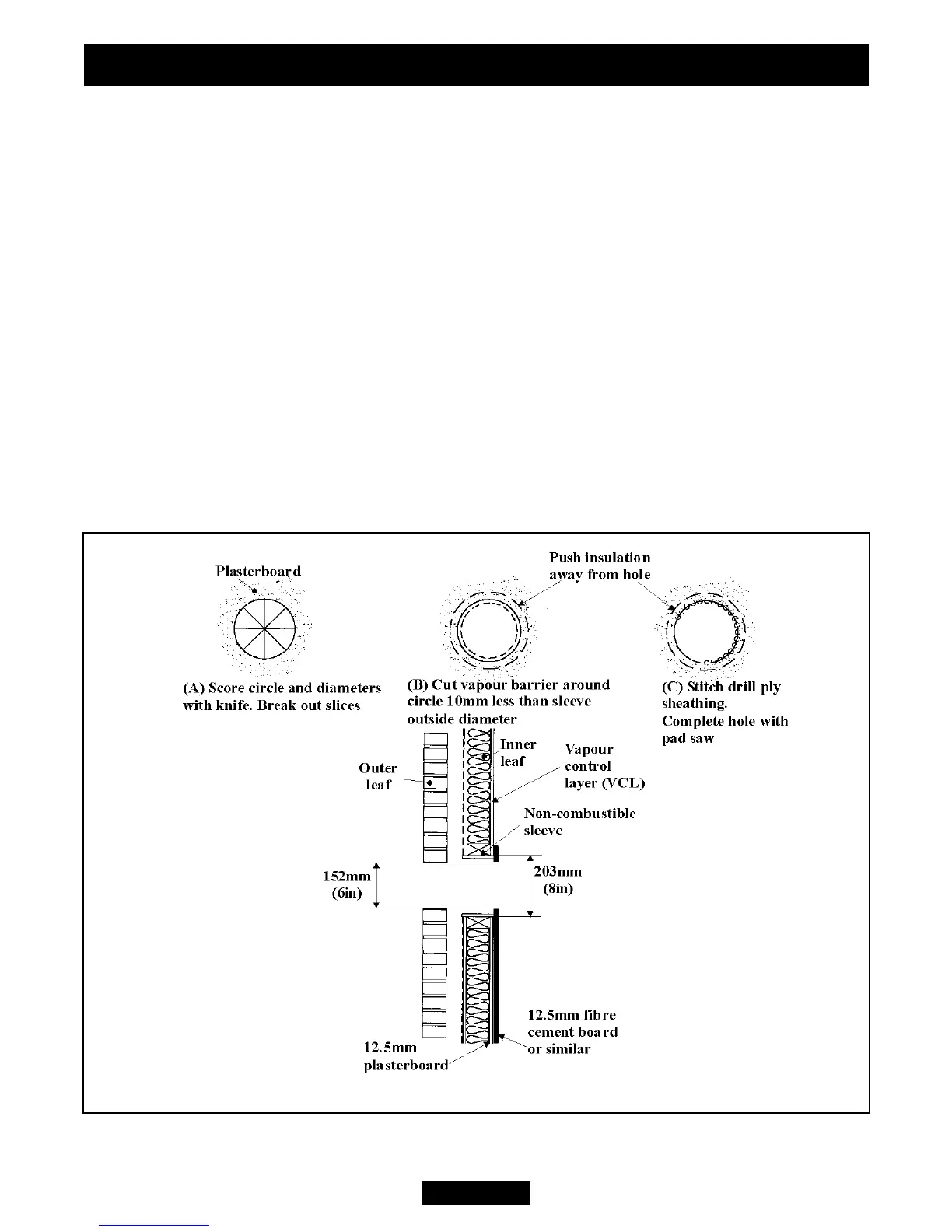

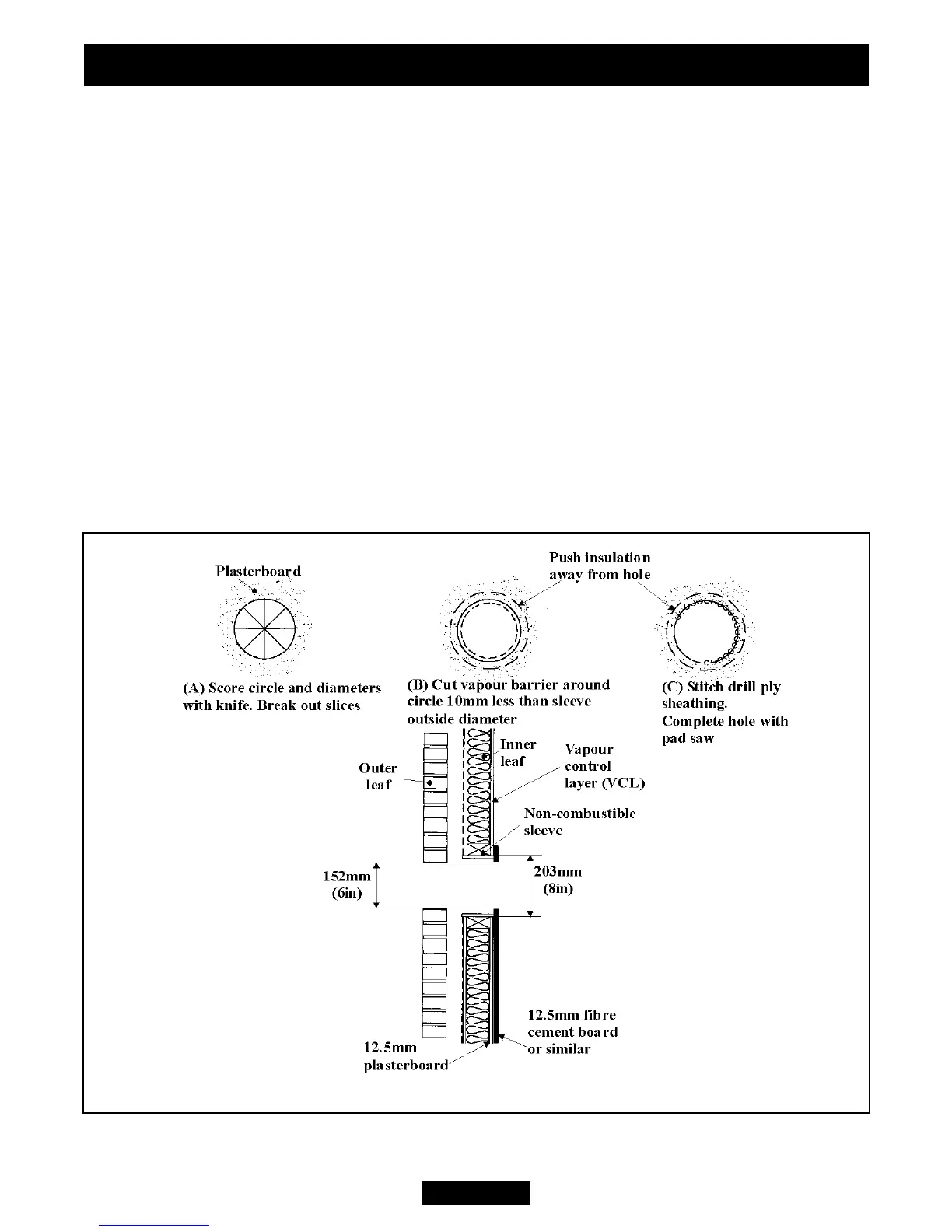

8.5 Cutting the flue hole in timber frame buildings.

Drill the pilot hole and hole in outer wall as section 8.4.

Since the flue will pass through combustible material in the inner leaf of the wall, a

non-combustible sleeve 203mm (8in.) diameter will be required round the flue (See

figure 12).

Cut a hole through the inner leaf to accommodate a non-combustible sleeve

203mm (8in.) outside diameter. To minimise the effect of breaking through the vapour

control layer (VCL), if possible, cut the hole approximately 10mm undersize so that

the sleeve will be forced through the layer. A recommended technique for cutting the

inner leaf is shown in figure 12.

Fit the non-combustible sleeve to the inner leaf. The sleeve must extend to be at

least flush with the breather membrane/timber sheathing but must not protrude more

than 10mm into the cavity.

The annular gap between the flue unit and the sleeve must be sealed to prevent

air heat and moisture passing along it. The 12.5mm insulating sheet (See section 8.3)

can be used for this. Do not permanently fix the insulating sheet to the wall at this

stage (See section 9.2).

INSTALLER GUIDE

Page 24

© Baxi Heating U.K. Limited 2010.

Figure 12. Timber frame wall preparation

Loading...

Loading...