39

6 Set up with the display and adjustment module

MINITRAC 31 • 4 … 20 mA/HART - four-wire

40447-EN-130430

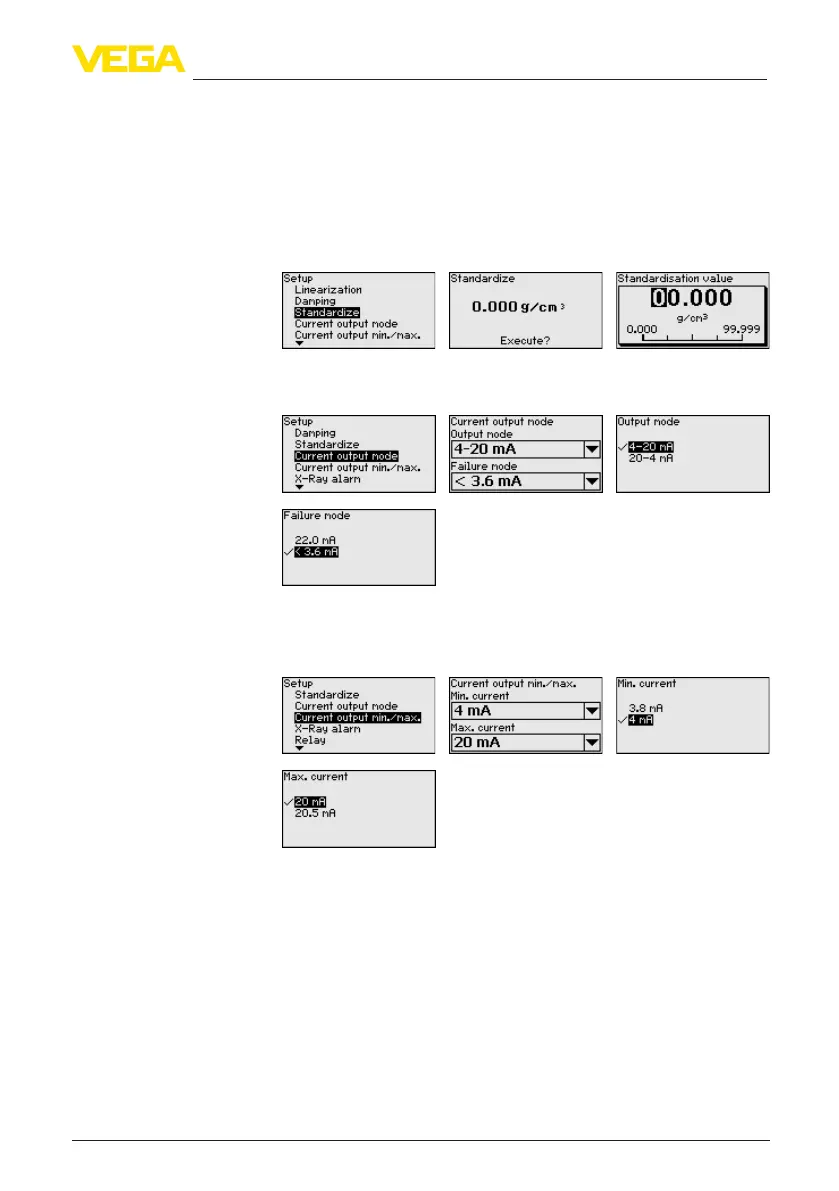

The implementation of a real value corretion is only necessary if the

requirements of the measurement loop have changed, for example

with abrasion in a tube.

If you know the density of a certain medium, you can enter the deter-

mined real density in this menu item to correct the measured value.

Thefunctionshiftsthelinearizationcurvetothisdeterminedpoint.

The measurement can thus be adapted exactly to the conditions in

the tube.

Inthismenuitemyoucandenethecharacteristicsofthesensorand

its behaviour in case of a fault.

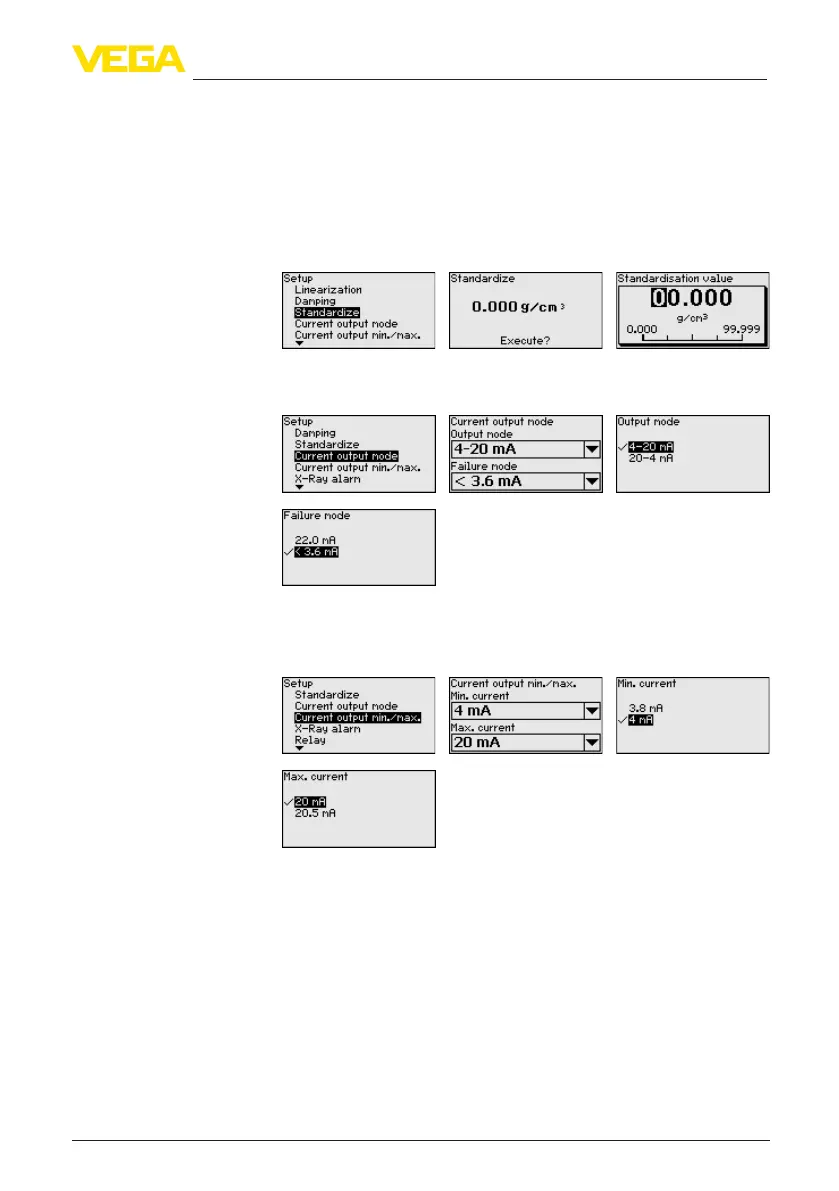

Inthismenuitemyoucandenethebehaviourofthecurrentoutput.

You can specify the current at minimum and maximum density sepa-

rately.

Radiationfromexternalsourcescaninuencethemeasuringresultof

the sensor.

Possible external radiation sources can be, for example, a weld joint

test on a neighbouring facility or other radiation-based instruments.

An X-ray alarm is triggered if the impulses (ct/s) are more than 25 %

abovethemax.valuefromthelinearizationtable.

This fault message is only outputted for the period of the increased

X-ray radiation. Then the fault message is automatically reset.

In this menu item you can determine the behaviour of the sensor

when external radiation sources appear.

Setup/Real value correc-

tion (manually)

Setup/Curr

ent output

mode

Setup/Curr

ent output

Min./Max.

Setup/External radiation

alarm

Loading...

Loading...