- 4-

Make Duct Connections

ERV500i

Port locations for the indoor unit are labeled in

Appendix B-1.

An 18" [457mm] long section of straight duct must be

used immediately after the supply fan to achieve optimal

fan performance. Transitions (field supplied) may be

required to make connection with ductwork that is

properly sized for minimum noise and pressure loss. Both

duct connections to outside must be insulated to avoid

condensation and heat loss. A continuous integral vapor

barrier must be used over the duct insulation.

Airflow rate balancing dampers are recommended for

both supply and exhaust ducts to allow for adjustment of

airflows as shown in Appendix D-1. Flexible connectors

should be installed close to the unit in the duct leading to

occupied spaces to minimize noise transmission. All ports

have 1" [25mm] flanges to facilitate duct connection.

Ensure that fasteners used to make duct connection

do not interfere with fans or dampers in the unit.

Electric preheat, if used as frost control, must be

installed in the intake from outside at a minimum distance

from the unit port of 24" [610mm].

ERV500e

On vertical discharge units, secure all ducts to the

roofcurb and building structure. Do not secure ductwork

to the unit. For duct size requirements, see Appendix B.

Insulate and weatherproof all external ductwork, joints

and roof openings with counter flashing and mastic in

accordance with applicable codes. Ductwork running

through roof decks must comply with local fire codes.

Ducts passing through unconditioned spaces must be

insulated and covered with a vapor barrier. Flexible

connectors should be installed close to the unit in

the duct leading to occupied spaces to minimize noise

transmission.

Rigging And Placing The Unit (ERV500e ONLY)

Inspect the exterior and interior of the equipment for

damage. Ensure there is no damage to internal compo-

nents such as fans, motors, dampers, enthalpy wheel,

insulation and structures. File a claim with the shipping

company if the unit is damaged.

Spreader bars are required to prevent damage to the

roof flange. Rollers may be used to move the unit across

a roof. Lifting holes are provided in the base rails as shown

in Appendix C. For weights and overall dimensions, see

Appendix B-2.

Location

Maintain clearance around and above the unit to pro-

vide proper airflow and service access. The fresh air

intake hood must be positioned away from sources of

contamination such as chimneys, exhaust vents, etc.

Positioning the fresh air intake opposite to the prevailing

winds will reduce entry of snow or moisture during periods

of high winds.

Install Hoods (ERV500e ONLY)

Intake and exhaust hoods for these models are shipped

separately from the unit. See Appendix C for hood installa-

tion information. A quick connect for the damper motors is

provided to connect to the main body of the unit. Make

sure that all screws are secured to maintain proper support

and keep seals watertight.

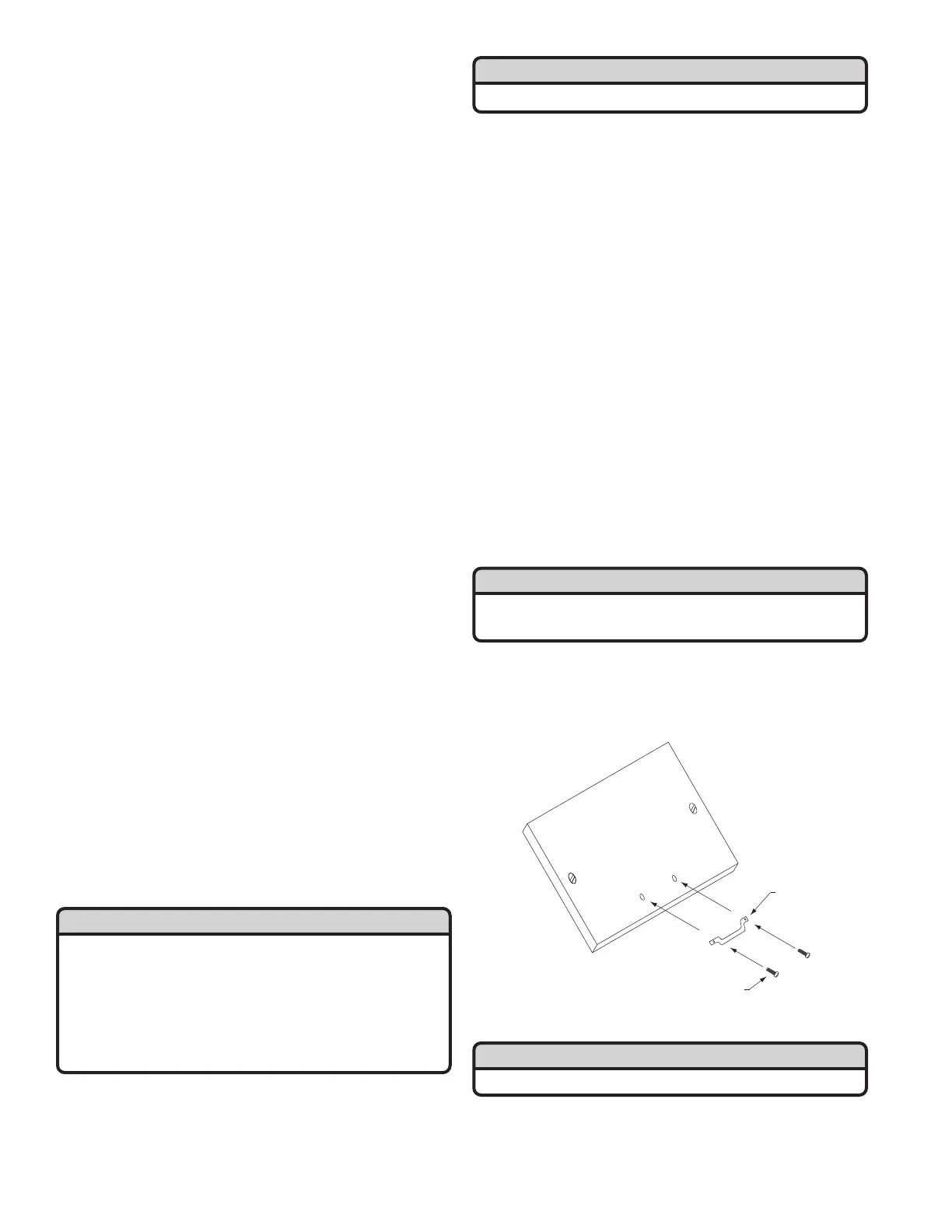

Install Access Panel Handles

Handles for access panels are provided but must be

installed on site. Handles and fasteners are secured on

the top of the unit. Remove from packaging and install

according to drawing below.

Remove All Internal Packaging

Remove access panels and remove all packaging from

the unit. Note that there is packaging for the wheel sup-

port during shipping. Removal of all of this packaging is

critical.

Metal/or

Polyamide

Handle

#10 x 3/4 Screw

Access Panel

CAUTION

All panels must be in place when rigging.

CAUTION

Remove all ERV wheel packaging prior to start up.

IMPORTANT

The hoods for these units are not installed from the fac-

tory and must be installed on-site. They can be installed

prior to rigging the unit or after the unit is installed.

Hoods are shipped on top of the unit. When rigging the

unit, ensure that the hoods are secured and are not

damaged by the spreader bars. See Appendix C for

hood installation and rigging information.

IMPORTANT

Securing door fasteners too tightly has negative effects

on the door gasket and should be avoided.

Loading...

Loading...