- 7-

Airflow Balancing

For proper performance the unit must operate with

equal supply and exhaust flow rates. Flow Measuring

Stations (FMS) and magnehelic gauges can be used to

measure and compare supply flow with exhaust flow.

Appendix D shows proper installation of the FMS in the

"exhaust air from space" and "supply air to space" ducts

for measuring exhaust and supply flows respectively.

It is important to locate the FMS in the "warm side"

ductwork as described above to minimize the effect of dif-

ferences in air density, especially when balancing during

extreme cold outside conditions. Air density variations

can effect the FMS by more than 15%.

The FMS should be located downstream from straight

sections of duct and not immediately after fans or

obstructions that will cause turbulent flow. See Appendix

D which illustrates minimum distances from fan, elbows

or transitions for best operation.

Flow control dampers should be installed downstream

from the FMS so flow through the FMS is not disturbed.

Dampers can then be adjusted to equalize flow rates in

the ducts.

Setting Flow Rate

Flow rates should be balanced with units operating on

high speed. A damper must be used to establish the min-

imum duct pressure required so fans do not operate in

overload regions. See Appendix G for airflow perfor-

mance charts. Set the dampers to establish the minimum

duct pressure required. Further adjust the dampers to

reduce flow to the desired, balanced rate.

System Service

Quarterly Maintenance

Quarterly maintenance (every three months) should

include:

Air Filters

The standard medium efficiency filters are disposable

and should be replaced every three months. More fre-

quent replacement may be required under extremely

dirty operating conditions. For filter specifications, see

Appendix F.

Cassette Panels and Interior of Unit

The foil-faced insulation surfaces and cassette panels

should be wiped clean with a soft cloth and mild cleaning

solution.

Annual Maintenance

Annual maintenance should include:

Air Filters

Replace medium efficiency filters.

Interior of Unit

Wash the foil-faced insulation surfaces with a soft cloth

and mild cleaning solution.

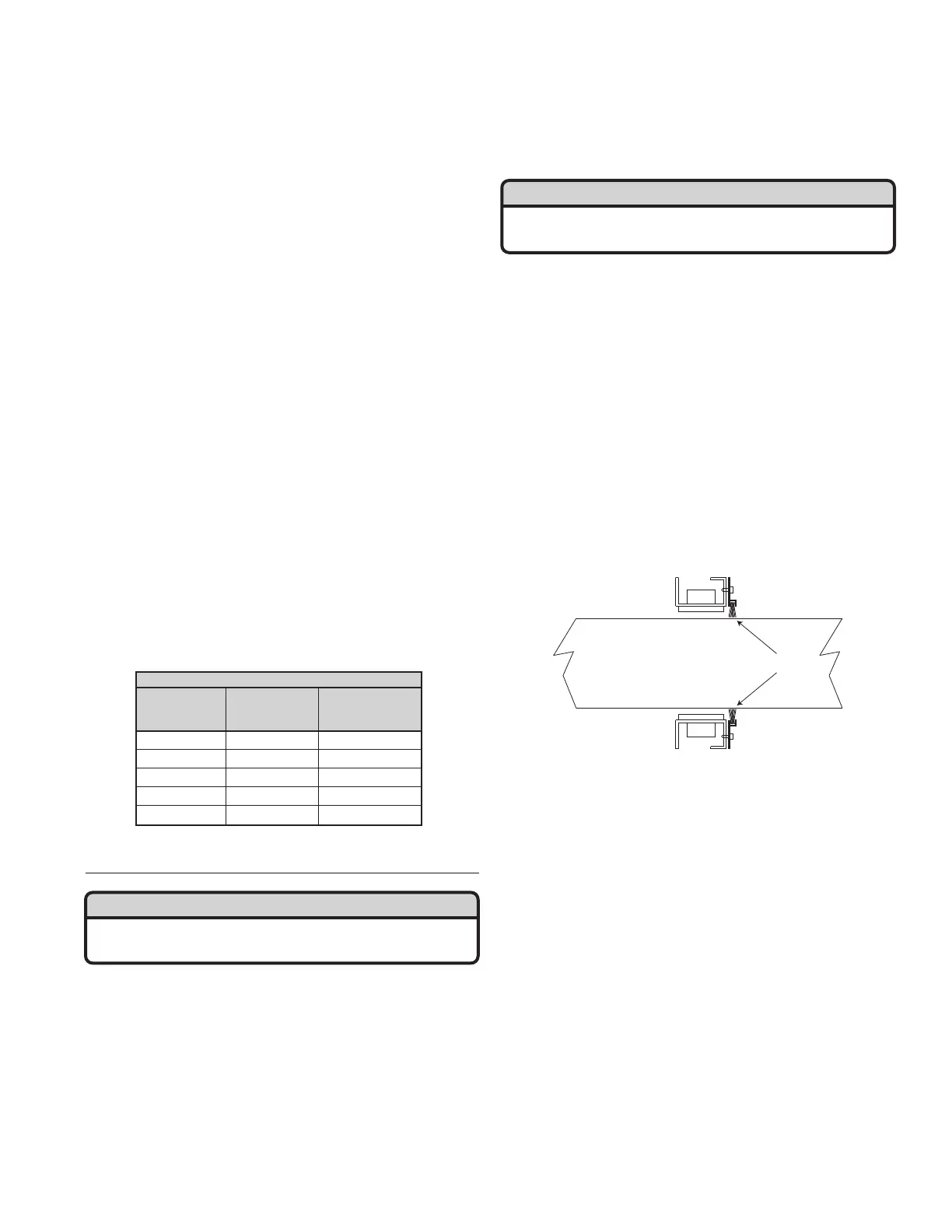

Enthalpy Wheel

No cleaning of the enthalpy wheel is required, it is self-

cleaning due to the opposing airflows. If the enthalpy

wheel needs to be cleaned; use low pressure air or a

vacuum. Wash the cassette panels with a soft cloth and

mild cleaning solution. Visually inspect the cassette brush

seals (shown below), perimeter seal and drive belt for

proper operation.

Fans

The blower wheels and fan housing should be checked

for dirt build-up. If they are dirty, it will be necessary to

remove the blower assembly to clean the dust out

through the fan mouth.

System Operation Check

Verification of all control modes should be checked to

ensure proper operation. Refer to Start Up Section.

Testing And Replacement Of The Damper

Actuator

After disconnecting the power from the unit, determine

if the actuator is defective. Disconnect the 24v power

source. Connect the actuator directly to a 24v power

source with an appropriate cable. If the damper operates

correctly, the problem is either in the wiring connections

or main circuit board.

If the actuator does not work, it must be replaced.

Loosen the nuts on the jack shaft clamp, remove the actu-

ator. Tighten the clamp on the damper jack shaft. Test for

proper operation.

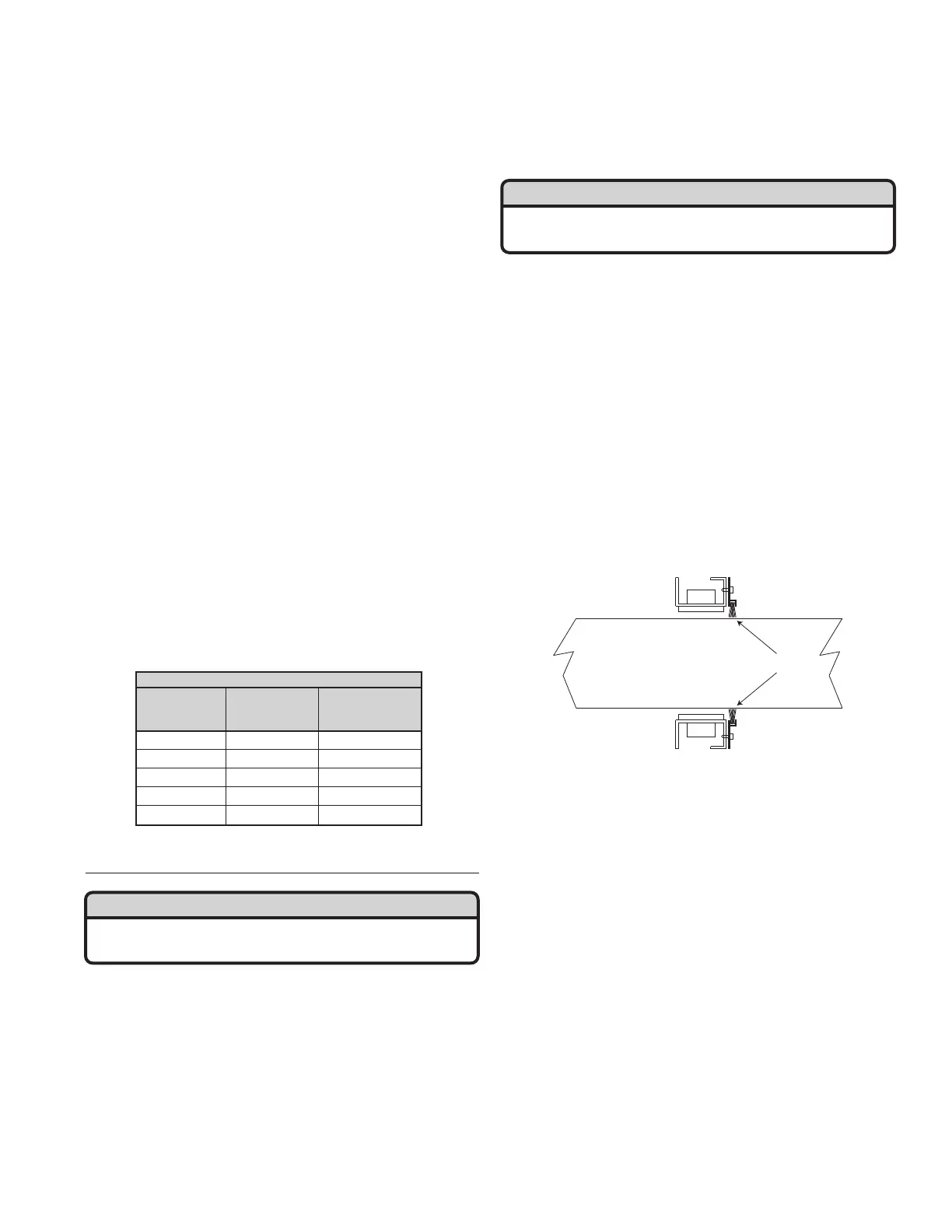

ERV500i/e ROTOR

18" Dia. 8" Depth Press. drop

cfm fpm in W. G.

300 417 0.45

400 556 0.60

500 695 0.76

600 834 0.93

700 973 1.10

WARNING

Disconnect the main power switch to the unit before

performing service and maintenance procedures.

WARNING

Disconnect the main power switch to the unit before

performing service and maintenance procedures.

Loading...

Loading...