AIRSUPPLYREQUIREMENTS

The required air pressure for Series 769 FireLock NXT Preaction Valves

is 13 psi/0.9 Bar minimum, regardless of the system supply water pres-

sure. Normal air pressure should not exceed 18 psi/1.2 Bar. Failure to

maintain air pressure within the 13 psi/0.9 Bar to 18 psi/1.2 Bar range

may reduce system operation response time.

Systems with air pressure higher than 18 psi/1.2 Bar may require the

addition of a Series 746-LPA Dry Accelerator. NOTE: The Series 746-

LPA Dry Accelerator must be used only on systems operating below

25 psi/1.7 Bar of air. If air pressure higher than 25 psi/1.7 Bar is required,

the Series 746 Dry Accelerator should be used.

If multiple Series 769 FireLock NXT Preaction Valves are installed with

a common air supply, isolate the systems with a spring-loaded, soft-

seated ball check valve to ensure air integrity for each system. Good

practice is to include a ball valve for isolation and service of each

individual system. Multiple valves require shop air or a tank-mounted air

compressor.

Set the air pressure to the required system air pressure. Air pressure

differing from the required system air pressure could delay system

operation response time.

The engineer/system designer is responsible for sizing the compressor

so that the entire system is charged to the required air pressure within

30 minutes. DO NOT oversize the compressor to provide more airflow.

An oversized compressor will slow down or possibly prevent valve opera-

tion.

If the compressor fills the system too fast, it may be necessary to

restrict the air supply. Restricting the air supply will ensure that air

being exhausted from an open sprinkler or manual release valve is not

replaced by the air supply system as fast as it is being exhausted.

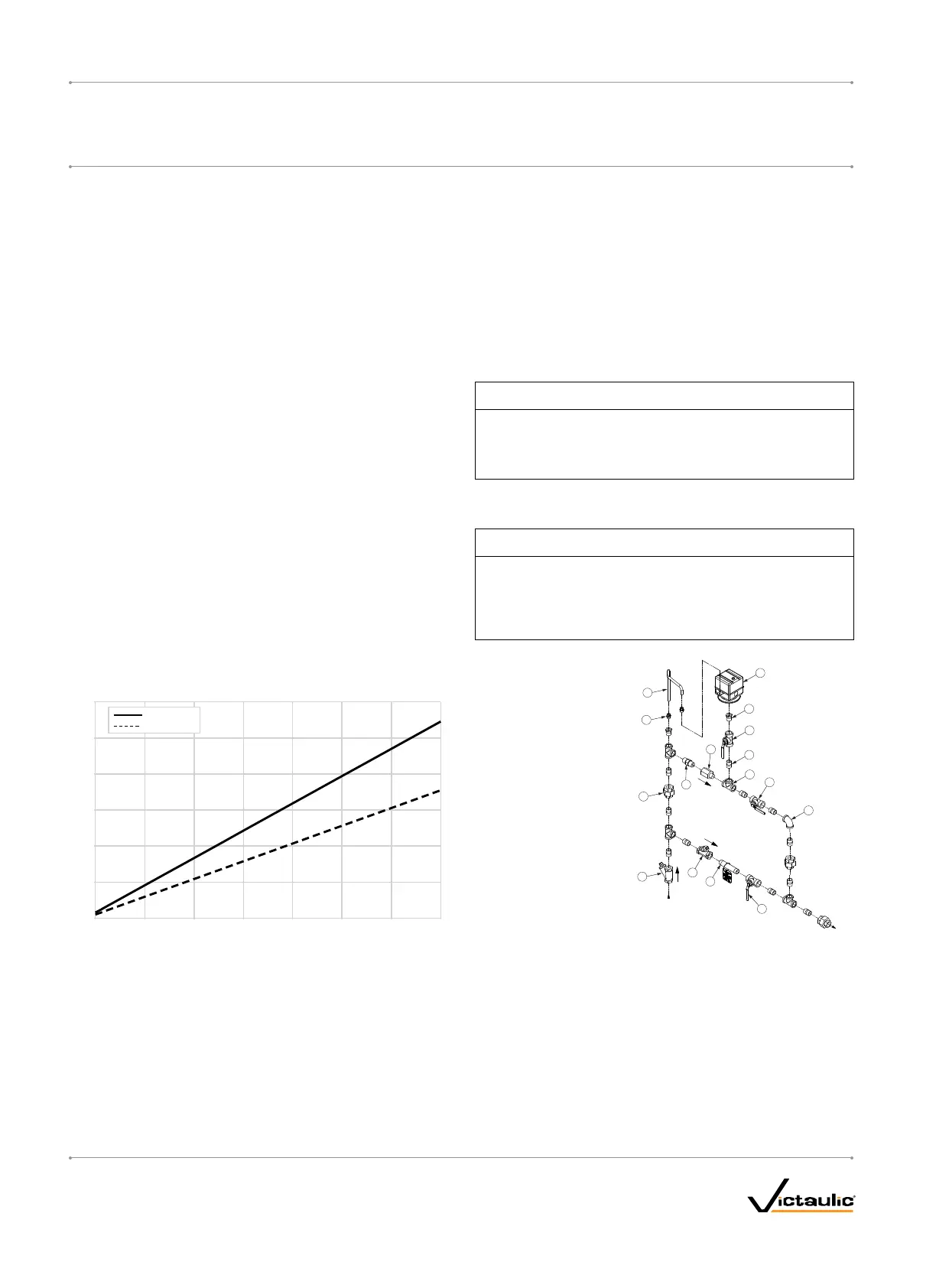

COMPRESSORSIZING

0

2

4

6

8

10

12

SYSTEM CAPACITY (in gallons)

REQUIRED FLOW RATE (CFM)

COMPRESSOR REQUIREMENTS

550

300

50

800

1050

1300

1550

1800

20 psi/138 kPa

13 psi/90 kPa

BASEORRISER-MOUNTEDAIRCOMPRESSORS

For base or riser-mounted air compressors, the recommended air

pressure of 13 psi/0.9 Bar is the “on” or “low” pressure setting for

the compressor. The “off” or “high” pressure setting should be

18 psi/1.2 Bar.

When a base or riser-mounted air compressor supplies air to a Series

769 FireLock NXT Preaction Valve, do not install the Victaulic Series

757 Regulated Air Maintenance Trim Assembly (AMTA). In this case,

the air line of the compressor connects to the valve trim at the air

manifold (refer to the applicable trim drawing). If the compressor is not

equipped with a pressure switch, the Series 757P Air Maintenance Trim

Assembly with Pressure Switch should be installed.

NOTICE

• TheSeries757PAMTAmustnotbeusedinanysystem

installedwithaSeries746-LPADryAccelerator,unlessatank

andanairregulatorareadded.

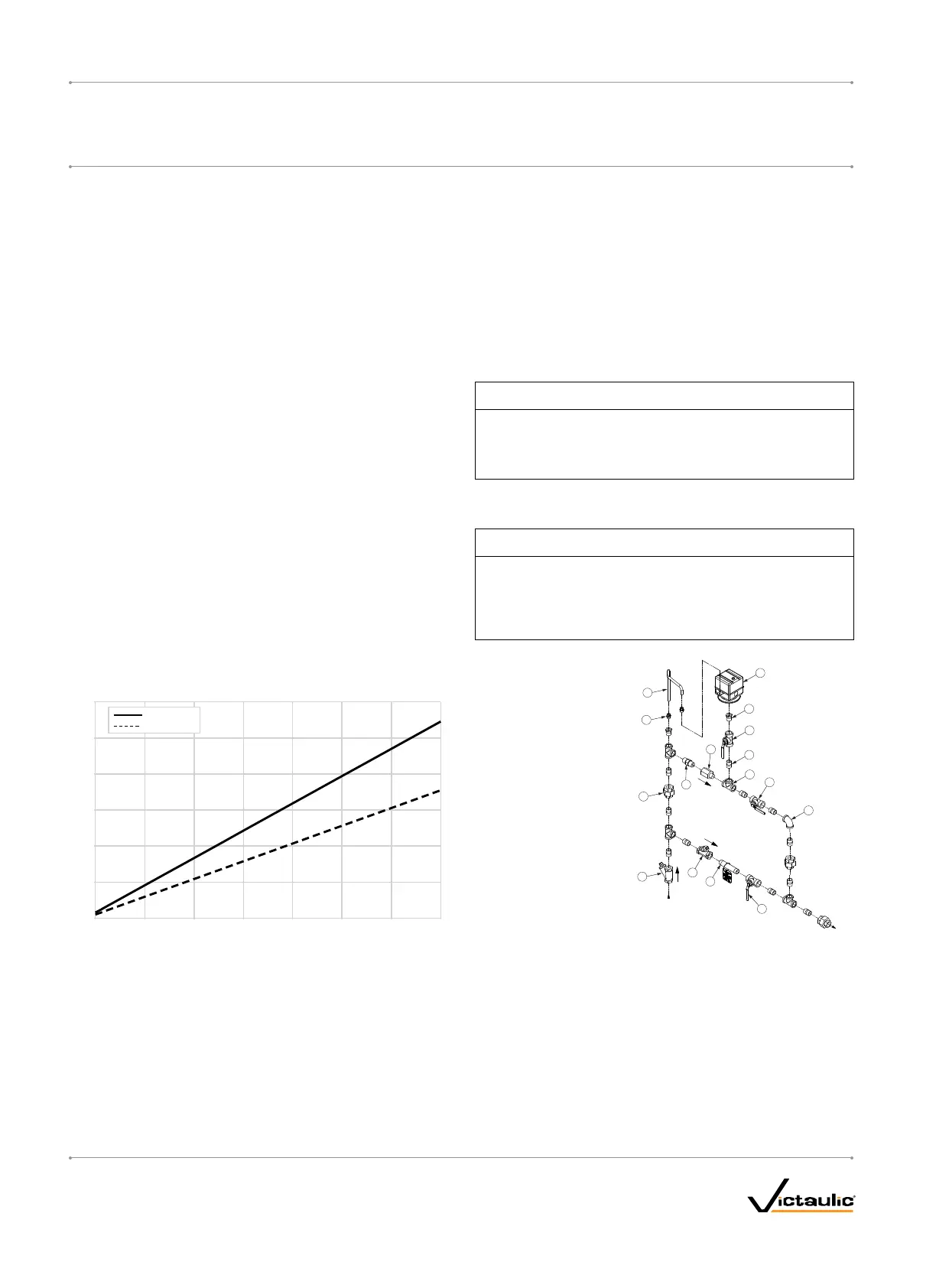

VICTAULICSERIES757PAIRMAINTENANCETRIMASSEMBLY

(AMTA)WITHPRESSURESWITCHOPTION

NOTICE

• RefertotheI-757PAirMaintenanceTrimAssemblywith

PressureSwitchInstallationInstructions,suppliedwiththe

product,forcompleteinstallation,electrical,andpressure

switchadjustmentinformation.

5

2

12

7

8

15

10

16

9

6

4

1

13

3

14

11

TO

SYSTEM

FROM

COMPRESSOR

Bill of Materials

Item Qty. Description

1 1 Restrictor (½-inch NPT)

2 1 Strainer (½-inch NPT)

3 1 Swing Check (½-inch NPT)

4 1 Slow-Fill Ball Valve

(Normally Open)

5 1 Spring-Loaded, Soft-Seated

Check Valve

6 1 Pressure Switch

7 2 Compression Fitting, Straight

(¼-inch NPT x ¼-inch Tube)

8 1 Copper Tubing (¼-inch OD)

9 11 Close Nipple

(½-inch NPT x 1.13)

10 1 Nipple (½-inch NPT x 4.00)

11 1 90° Female Elbow (½-inch NPT)

12 4 Female Tee (½-inch NPT)

13 3 Union (½-inch NPT)

14 2 Reducing Bushing

(½-inch NPT x ¼-inch NPT)

15 1 Fast-Fill Ball Valve

(Normally Closed)

16 1 Pressure Switch Isolation Ball

Valve (Normally Open -

Lockable)

I-769P.AC/ELEC_10

FireLockNXT™AutoConvertPreactionValve

SERIES 769

PreactionElectricAutoConvertDryTrim

I-769P.AC/ELEC

INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2009 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_B

Loading...

Loading...