INSTALLINGTHECOVERPLATEGASKETANDCOVERPLATE

CAUTION

UseonlyVictaulic-suppliedreplacementparts.•

Failuretofollowthisinstructioncouldcauseimpropervalve

operation,resultinginpropertydamage.

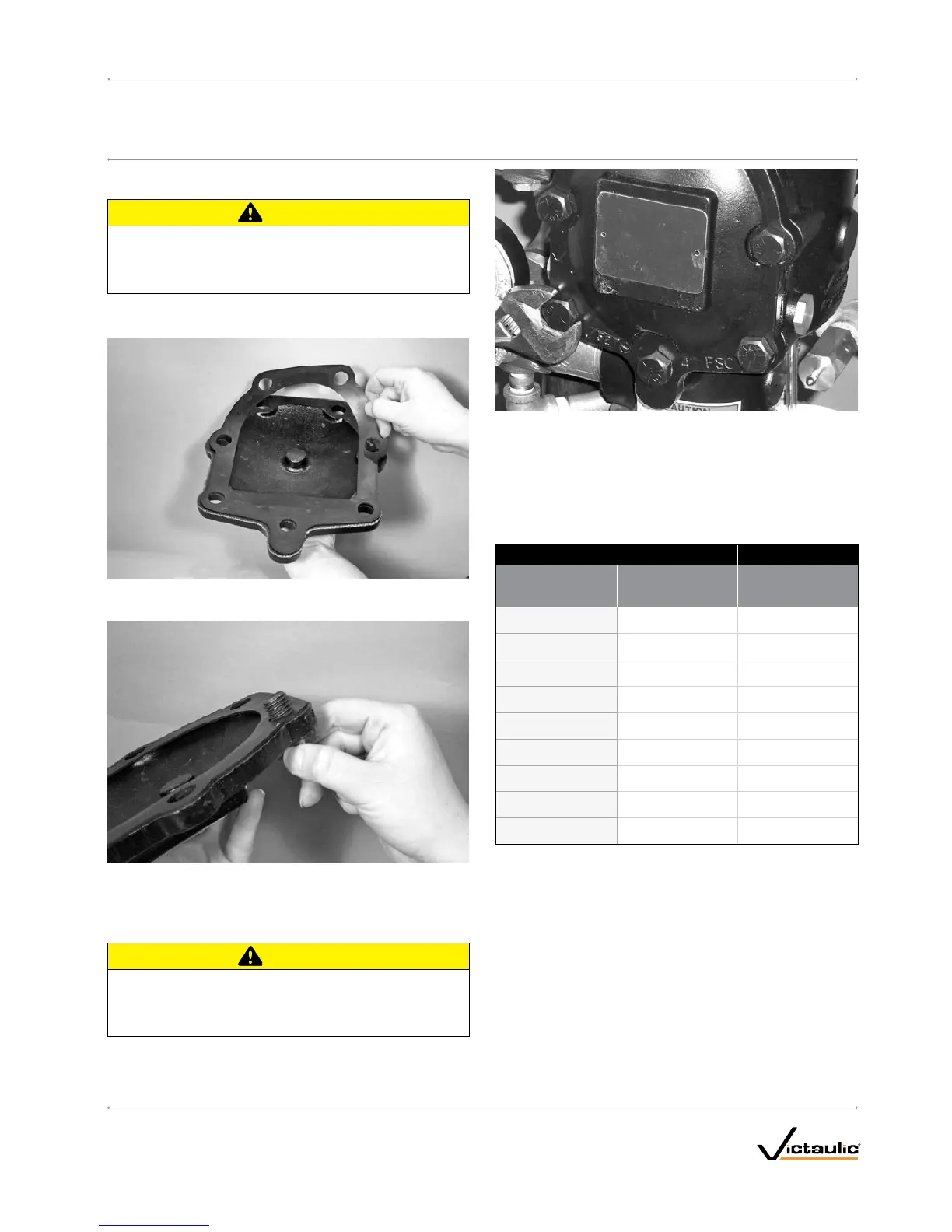

1. Verify that the cover plate gasket is in good condition. If the gasket

is torn or worn, replace it with a new, Victaulic-supplied gasket.

2. Align the holes of the cover plate gasket with the holes in the cover

plate.

3. Insert one cover plate bolt through the cover plate and cover plate

gasket to ease alignment. NOTE: For 1 ½-inch/48.3-mm and

2-inch/60.3-mm valve sizes, a washer must be re-installed under

the head of each cover plate bolt.

CAUTION

DONOTover-tightenthecoverplatebolts.•

Failuretofollowthisinstructioncouldcausedamagetothe

coverplategasket,resultinginvalveleakage.

4. Align the cover plate/cover plate gasket to the valve. Make sure the

clapper spring’s arms are rotated to their installed position. Tighten

all cover plate bolts into the cover plate/valve body.

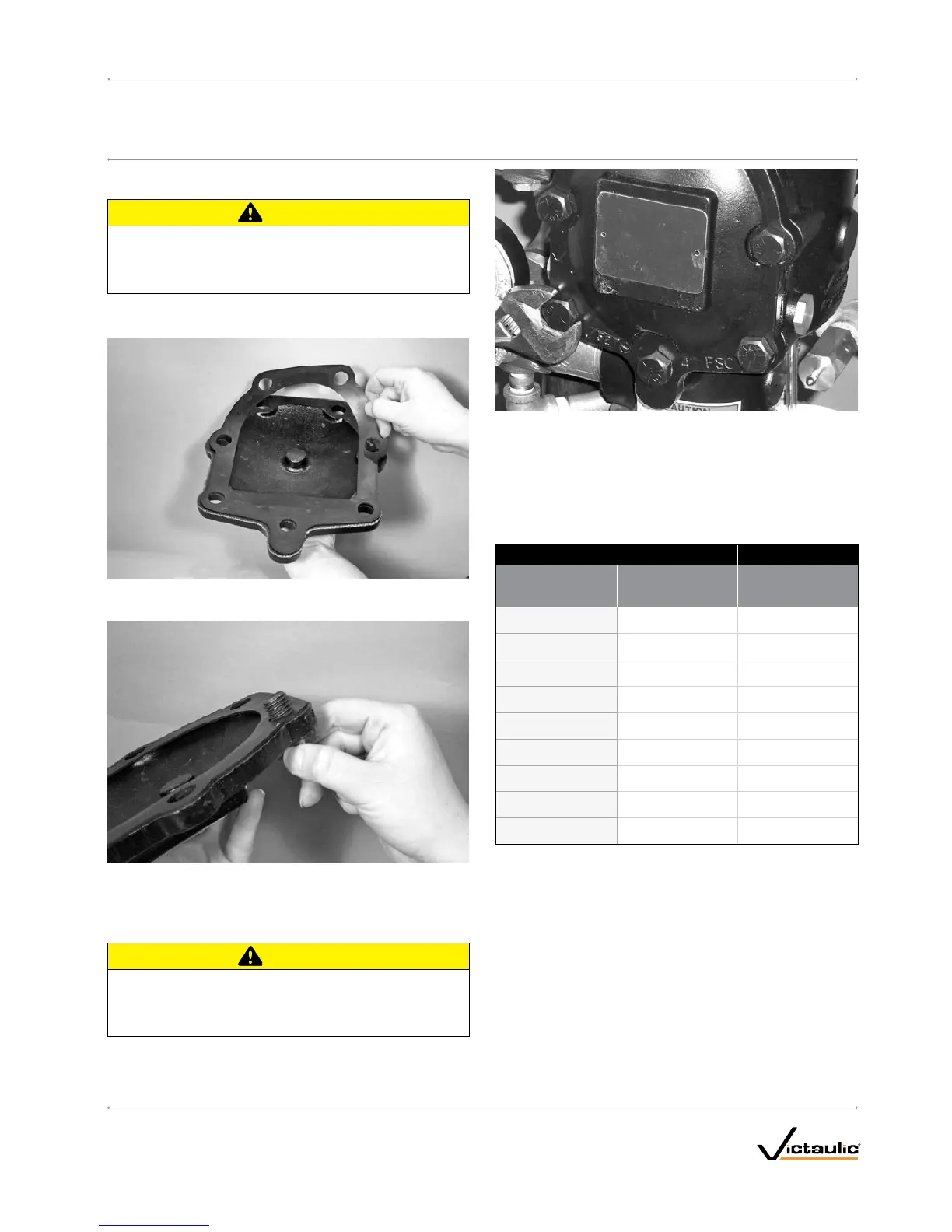

5. Torque all cover plate bolts in an even, crossing pattern. Refer

to the “Required Cover Plate Bolt Torques” table below for the

required torque values. DO NOT over-tighten the cover plate bolts.

REQUIREDCOVERPLATEBOLTTORQUES

Size Torque

NominalSize

inches

Actual

OutsideDiameter

inches

mm

ft-lbs

N•m

1 ½

1.900 30

48.3 41

2

2.375 30

60.3 41

2 ½

2.875 60

73.0 81

76.1 mm

3.000 60

76.1 81

3

3.500 60

88.9 81

4

4.500 100

114 . 3 136

165.1 mm

6.500 115

165.1 156

6

6.625 115

168.3 156

8

8.625 100

219.1 136

6. Place the system back in service by following the “Placing the

System in Service” section.

I-769D_41

FireLockNXT™DelugeValve

SERIES 769

I-769DINSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...