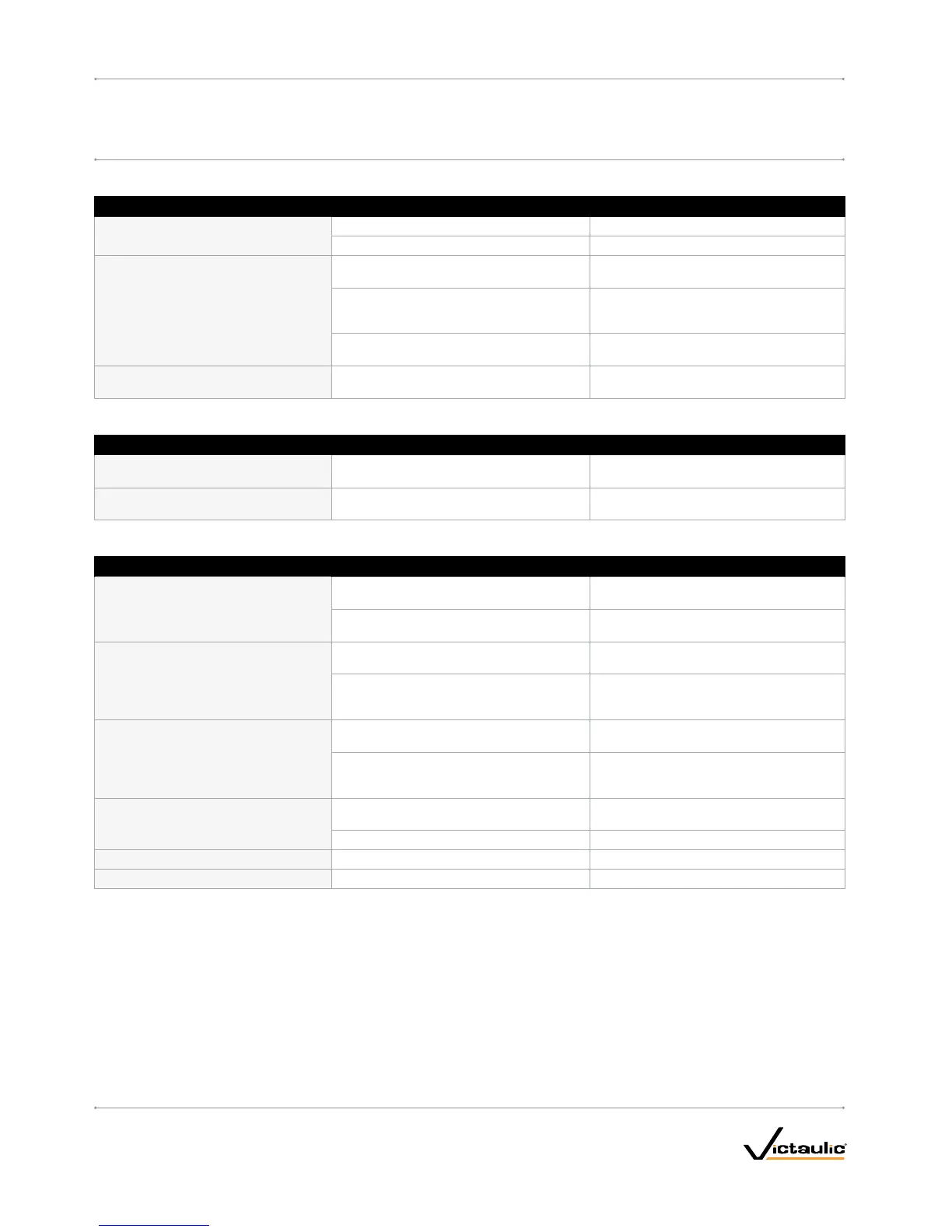

TROUBLESHOOTING–SERIES776LOW-PRESSUREACTUATOR

Problem PossibleCause Solution

When the Auto Vent Sleeve of the Series 776 Low-Pressure Actuator

is pulled up, the screw does not stay set in the “UP” position.

The Series 776 Low-Pressure Actuator is not receiving enough air. Increase the air pressure going into the Series 776 Low-Pressure Actuator.

The Series 776 Low-Pressure Actuator has a broken seal. If the above procedure does not work, contact Victaulic.

Water is Water is leaking through the Series 776 Low-Pressure

Actuator.

The air chamber of the Series 776 Low-Pressure Actuator is not set. Make sure the vent seal of the Series 776 Low-Pressure Actuator is in the

set position and the air chamber is pressurized.

The strainer on the Series 776 Low-Pressure Actuator is clogged. Replace the strainer screen of the Series 776 Low-Pressure Actuator.

Refer to the “Replacing the Strainer Screen for Series 776 Low-Pressure

Actuators” section.

The Series 776 Low-Pressure Actuator has a ripped diaphragm. If water still leaks through the Series 776 after performing the above

procedures, contact Victaulic.

No water is passing through the Series 776 Low-Pressure Actuator. The strainer on the diaphragm charge line is clogged. Disassemble and clean the diaphragm charge line strainer. Refer to the

applicable trim drawing for details.

TROUBLESHOOTING–SERIES753-ESOLENOIDVALVE

Problem PossibleCause Solution

No water is passing through the Series 753-E Solenoid Valve. The strainer on the diaphragm charge line is clogged. Disassemble and clean the diaphragm charge line strainer. Refer to the

applicable trim drawing for details.

The Series 753-E Solenoid Valve does not open. No power is going to the solenoid. Check all electrical connections to make sure power is being supplied to

the solenoid.

TROUBLESHOOTING–SYSTEM

Problem PossibleCause Solution

The valve operates without sprinkler activation. There is a loss of air pressure in the system or trim. Check for any leaks in the system and trim. Conrm that the AMTA is

operating properly. Consider installing a low-air supervisory switch.

The pressure switch on the air compressor is set too low, or the compressor

is not operating properly.

Increase the “ON” setting of the air compressor’s pressure switch, and check

the air compressor for proper operation.

Water is leaking from the drip check located in the alarm line. Water is getting past the clapper seal and into the intermediate chamber

of the valve.

Check the clapper seal and valve body seat ring for physical damage and

foreign material.

Water is under the clapper seal. Inspect the clapper seal to make sure no water is under the seal. If water is

present, remove and replace the seal. Refer to the “Removing and Replac-

ing the Clapper Seal” section.

Air is leaking from the drip check located in the alarm line. Air is getting past the clapper seal and into the intermediate chamber of

the valve.

Check the clapper seal and valve body seat ring for physical damage and

foreign material.

Water is under the clapper seal. Inspect the clapper seal to make sure no water is under the seal. If water is

present, remove and replace the seal. Refer to the “Removing and Replac-

ing the Clapper Seal” section.

The clapper will not latch closed. There is no water pressure on the diaphragm. Check the water pressure in the diaphragm charge line. Make sure the

restrictor in the diaphragm charge line is clean.

The Auto Drain is not set. Set the Auto Drain by pulling up on the Auto Drain Sleeve.

Water is leaking from the diaphragm assembly. The diaphragm is damaged. Contact Victaulic.

Air is leaking from the diaphragm assembly. The diaphragm is damaged. Contact Victaulic.

I-769D_44

FireLockNXT™DelugeValve

SERIES 769

I-769D

INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...