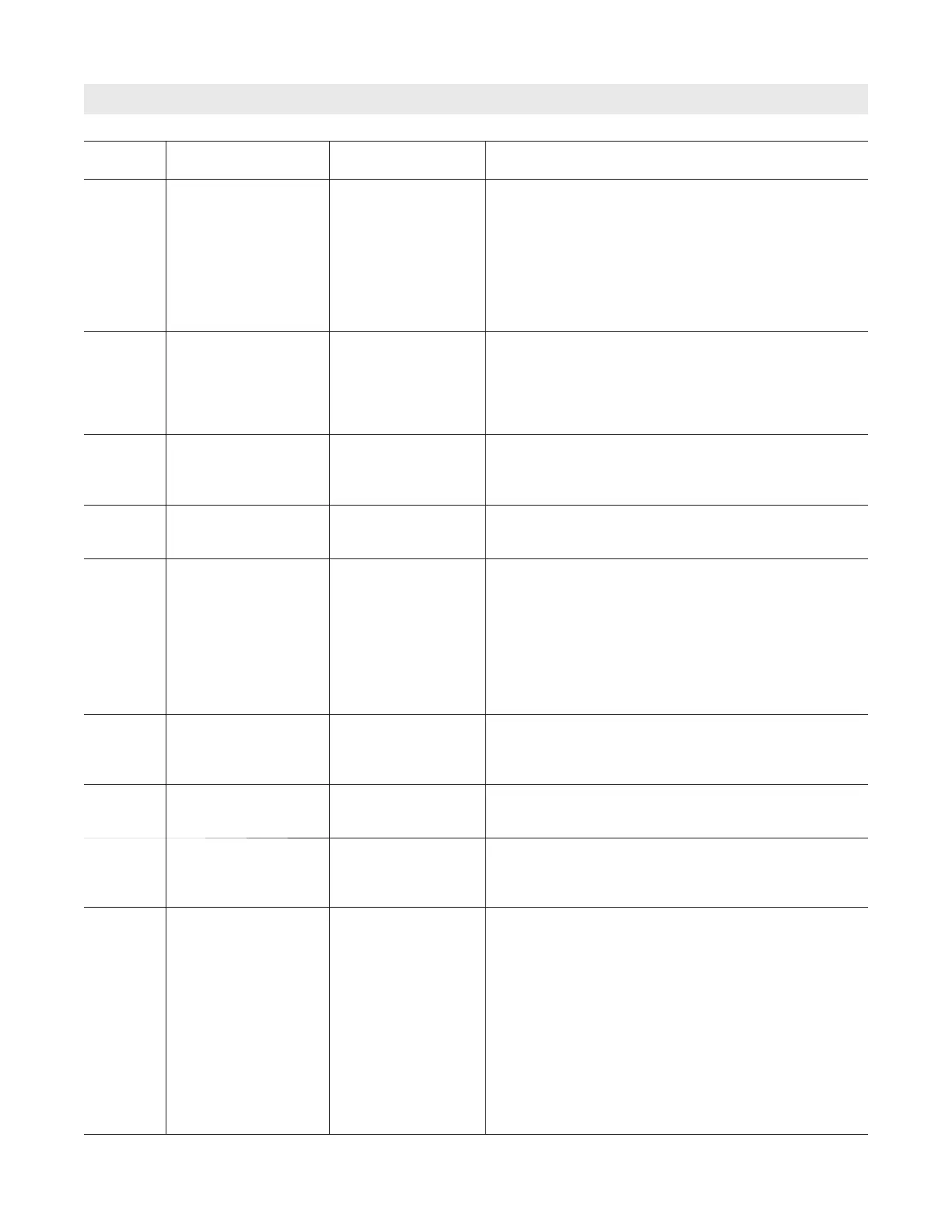

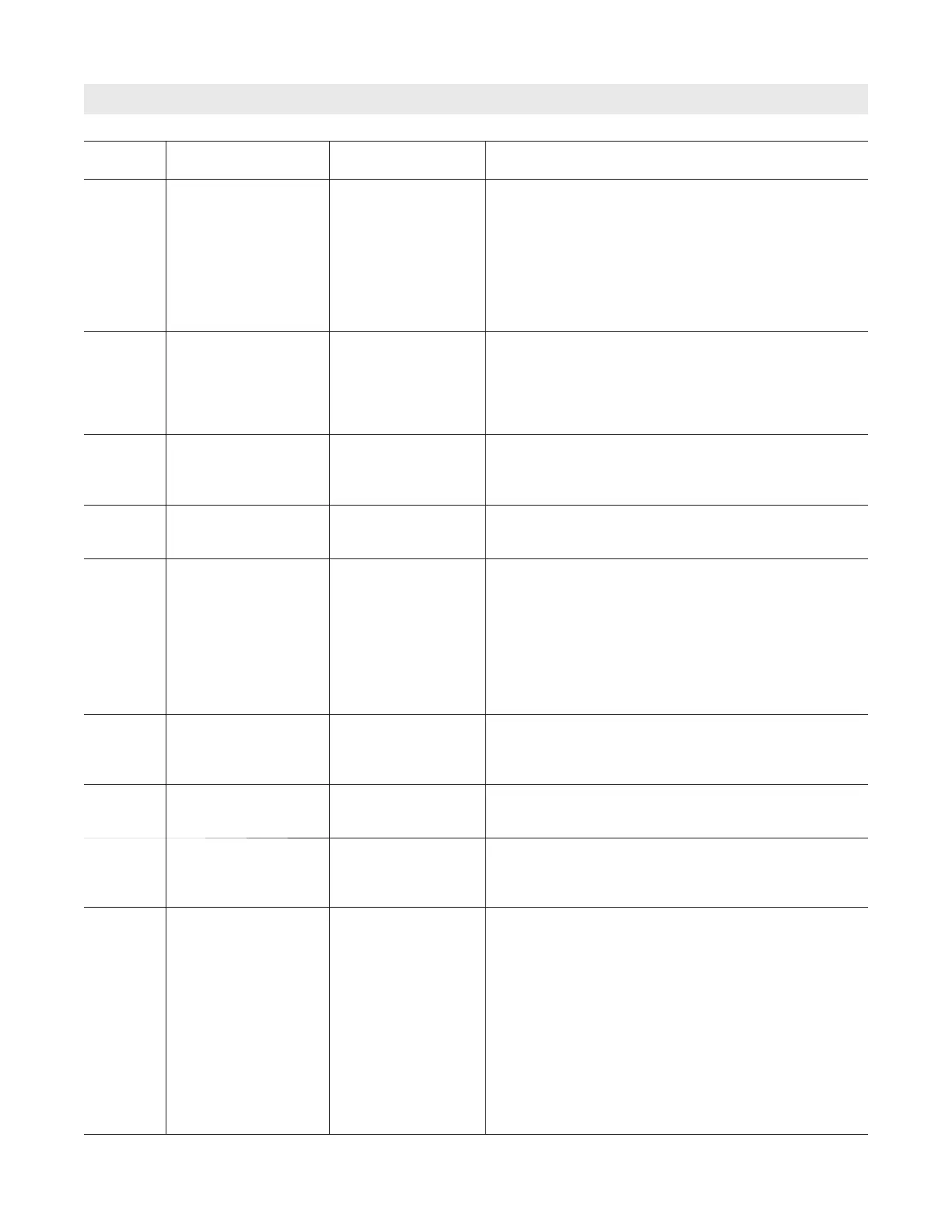

76

6167 818 - 10

Vitodens 100-W, B1HE/B1KE Combi Installation/Service

Fault Messages

(continued)

Troubleshooting

Displayed

fault code

System characteristics Cause Measures

F.346 Burner in a fault state Ionization current

calibration error

Check the gas supply pressure.

Check gas solenoid valve strainer on the inlet side

for contamination.

Check ionization electrode for contamination.

Check flue system. Remove flue gas recirculation

if necessary.

Check the connecting cable to the fan unit.

Check whether condensate is backed up.

Reset the boiler.

F.348 Burner in a fault state Gas modulation valve If several boilers are connected to a common flue

system:

Check whether “Multiple connections” is set in the

commissioning assistant.

Check the flue system for unrestricted flow.

If the fault persists, replace the gas fan unit.

F.349 Burner in a fault state Air mass flow rate not

detected correctly in

fan unit.

Check for dust contamination in the ventilation air.

Check flame body assembly for contamination.

Reset the boiler. If the fault occurs repeatedly, replace

the gas fan unit.

F.350,

F.351

Burner in a fault state Ionization current

lies outside the

permissible range

Replace BCU burner control unit:

See page 89.

F.352 Burner in a fault state CO limit within boiler

exceeded

Check entire flue gas path for the following:

Flue gas recirculation

Leaks

Flue gas back pressure caused by water pocket

(if flue system fall is insufficient)

Constrictions

Blockages

Repair flue system if necessary.

Reset the boiler.

F.353 Burner shutdown with

restart if demand exists

Insufficient gas supply,

burner output reduced

Check the gas supply.

Optically check input-side screen in the gas solenoid

valve for contamination.

Reset the boiler.

F.354 Burner in a fault state Gas modulation valve

tolerance outside

permissible range

Replace gas fan unit.

F.355 Burner in a fault state Analogue signal

reference check:

Flame signal is already

present at burner start.

Replace BCU burner control unit:

See page 89.

F.357 Burner in a fault state Insufficient gas supply

Check that the gas shut-off valve is open.

Optically check input-side screen in the gas solenoid

valve for contamination.

Test static gas pressure and gas flow pressure.

Check that on-site gas line and gas flow switch are

correctly sized.

Note: If the building pressure regulator has a leak, you

may notice rising pressure when the burner is idle.

When the system is restarted, the gas flow switch may

trip. If the static pressure doesn’t drop, check cable to

the fan unit. Check whether the coil resistance at the

fuel valve is approx. 4 k Ω (plug 35, contact 2 and 4).

Check the ignition electrode for damaged insulation.

Reset the boiler.

Loading...

Loading...