56

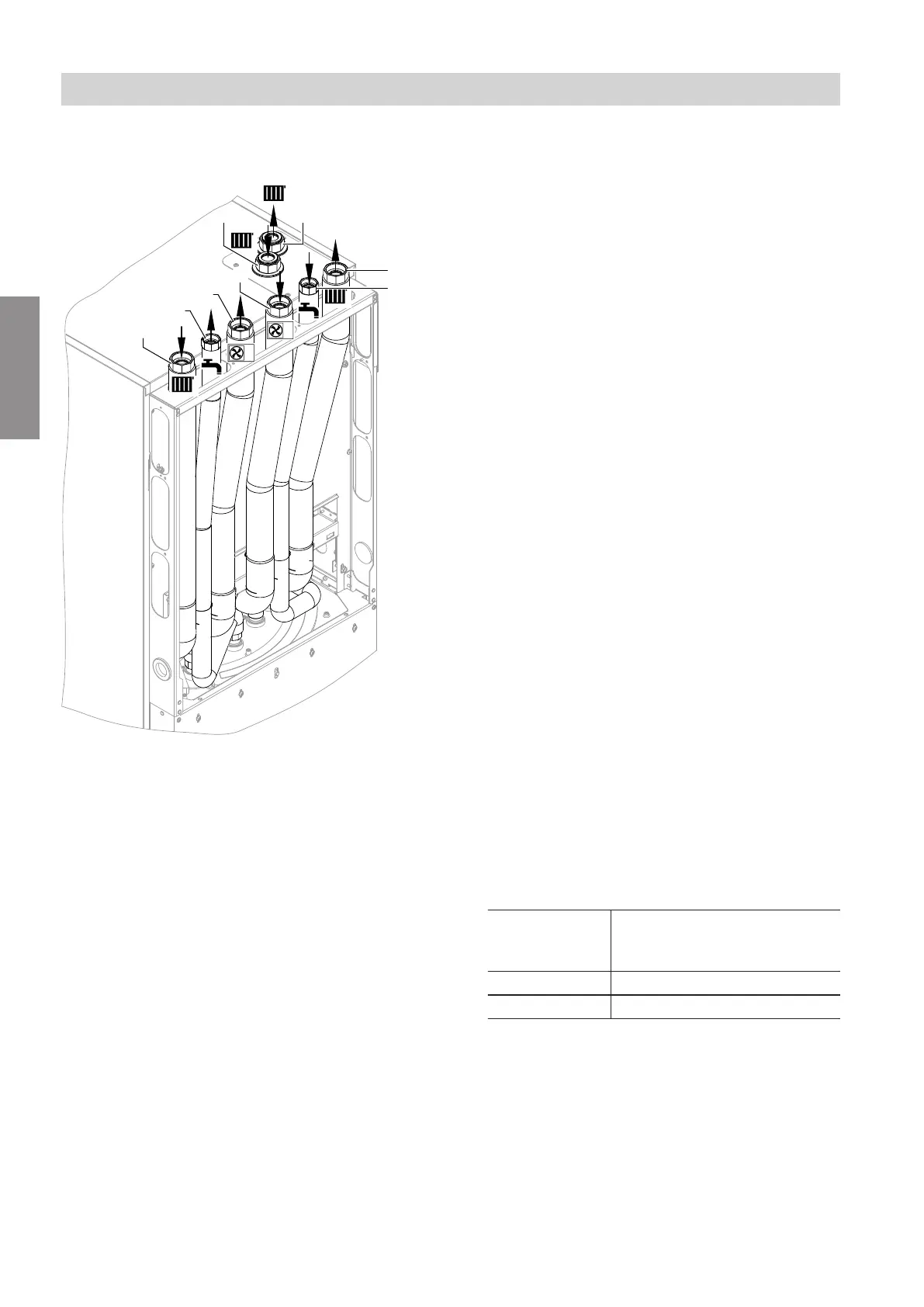

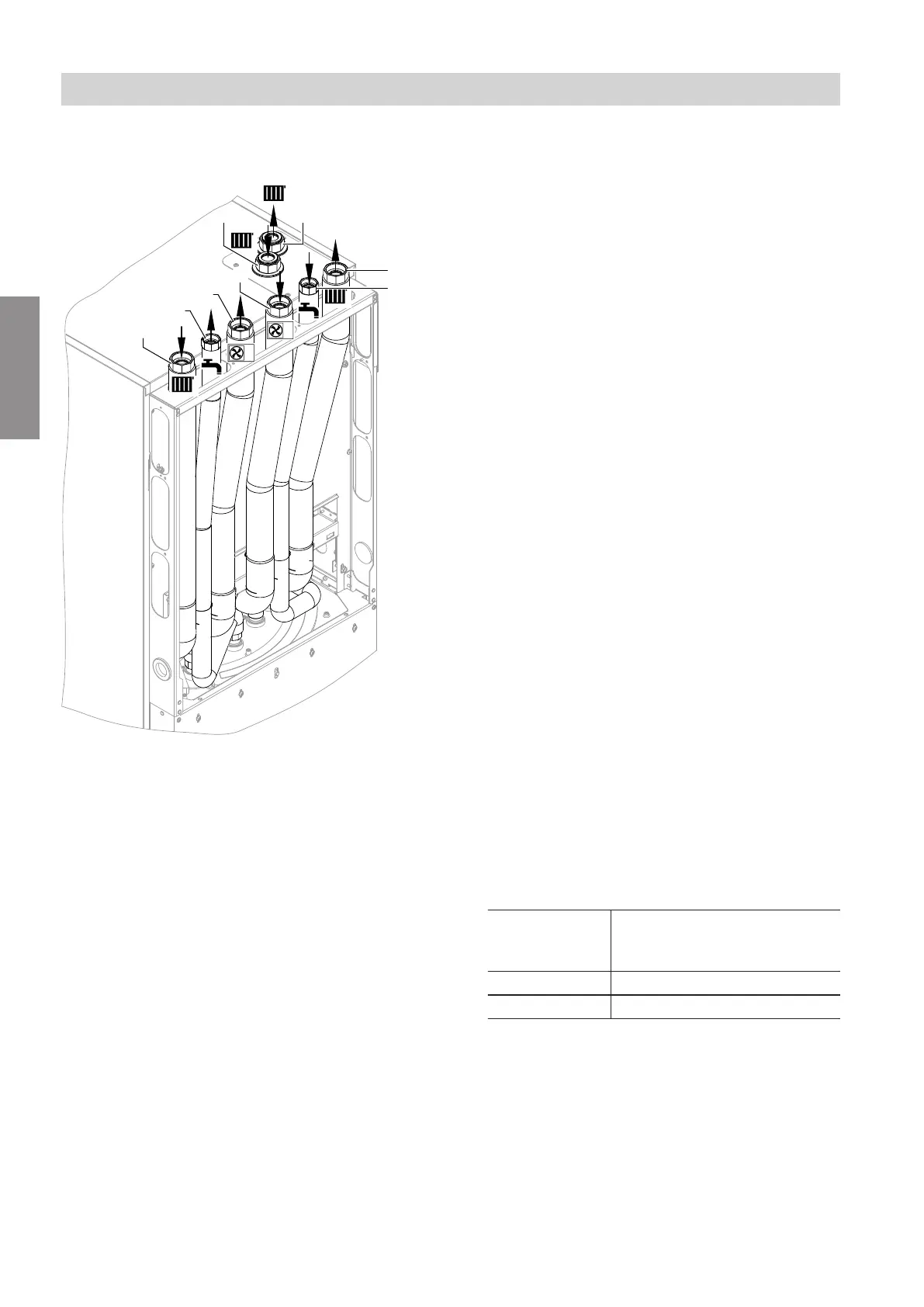

Indoor unit with 2 integrated heating/cooling cir-

cuits

Fig. 41

A

Heating water return, heating/cooling circuit 1:

G 1¼ (female thread)

B

DHW: G ¾ (female thread)

C

Heating water to outdoor unit: G 1¼ (female

thread)

D

Heating water from outdoor unit: G 1¼ (female

thread)

E

Cold water: G ¾ (female thread)

F

Heating water flow, heating/cooling circuit 1: G 1¼

(female thread)

G

Heating water return, heating/cooling circuit 2:

G 1¼ (female thread)

H

Heating water flow, heating/cooling circuit 2: G 1¼

(female thread)

Hydraulic connections

1. If the expansion vessel fitted in the indoor unit is

insufficient, equip the secondary circuit on site with

an additional expansion vessel.

2. Connect all secondary side hydraulic lines (room

heating/cooling, DHW heating) to the indoor unit.

!

Please note

Hydraulic connections subjected to mechani-

cal loads lead to leaks, vibrations and appli-

ance damage.

Connect on-site lines so that they are free of

load and torque stress.

Note

Recommendation: Install a suitable heating water

filter in the secondary circuit to remove magnetic

and non-magnetic dirt particles, e.g. the heating fil-

ter with magnetite separation (accessories).

!

Please note

Contamination in the secondary circuit will

lead to blockage of the hot water filter in the

outdoor unit.

Before making the hydraulic connection of

the indoor and outdoor unit, thoroughly flush

the secondary circuit.

3. Grease and connect the hydraulic connection lines

to the outdoor unit e.g. hydraulic connection set

(accessory).

4. Recommendation: Check for leaks with nitrogen.

5.

!

Please note

Leaking hydraulic lines and joints will cause

damage to the system or to the building.

Do not thermally insulate joints until after

completion of the leak test following filling:

See chapter "Building up the system pres-

sure".

Thermally insulate pipework inside the building. If

room cooling is planned for the building, use ther-

mal and vapour diffusion-proof insulation.

Pipework inter-

nal

7

Min. thickness of thermal in-

sulation layer with

λ = 0.035 W/(m·K)

≤ 22 mm 20 mm

> 22 mm 30 mm

λ Thermal conductivity

Hydraulic connections

Hydraulic connection of the indoor unit (cont.)

6222080

Installation

Loading...

Loading...