MR 700

30

Ed. 3 - 2012_11

English

ENGINE MAINTENANCE

The maintenance operations are subdivi-

ded into:

– Maintenance during running-in (rst 50

hours)

– Routine maintenance (after running-

in) The frequency stated in the “ routine

maintenance” table should be applied to

engines which are used regularly.

Some lubricants or components lose

their characteristics over time even if the

engine is left idle for long periods; the-

refore, maintenance intervals should be

established considering that these parts

need to be replaced not only on the basis

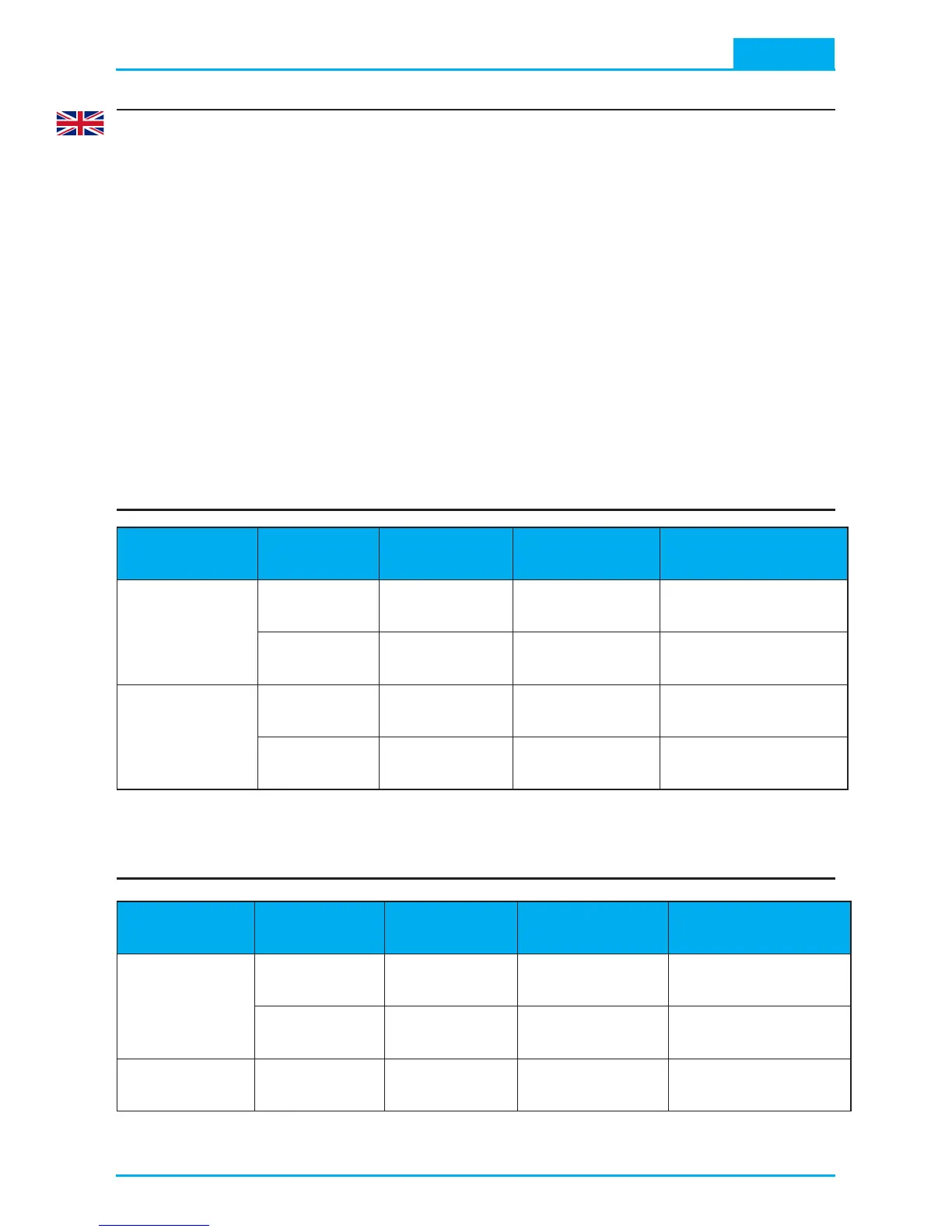

Maintenance during running-in table (rst 50 hours)

Frequency(5) Component

Type of in-

tervention

Intervention

procedures

Reference

Every 10

hours

Engine oil Level control

Top up, if nec-

essary

See “Engine oil

level control”

Coolant Level control

Top up, if nec-

essary

See “Engine cool-

ant level check”

After the rst

50 hours (at

the end of

running- in)

Engine oil

(1)

Replacement

See “Engine oil

change”

Oil lter (2) Replacement

See “Oil lter car-

tridge replacement”

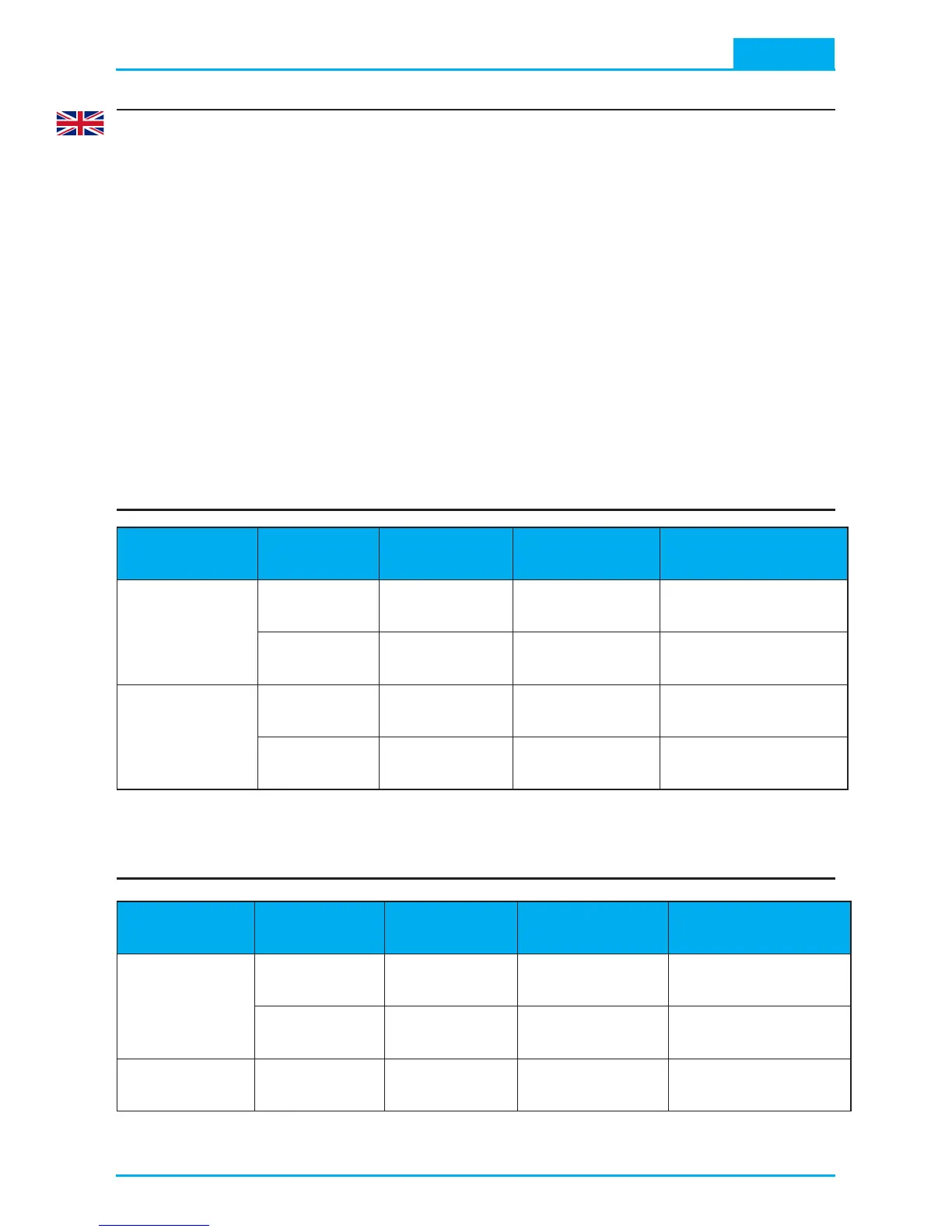

Routine maintenance table (after running-in)

Frequency(5)(5) Component Type of in-Type of in-

tervention

InterventionIntervention

procedures

Reference

Every 10

hours

Engine oil

(1)

Level controlLevel control Top up, if nec-

essary

See “Engine oilSee “Engine oil

level control”

Coolant (3) Level controlLevel control Top up, if nec-

essary

See “Engine coo-

lant level check”

Every 50

hours

Electrolytic

zinc

Integrity

control

Replace, if

necessary

See “Electrolytic

zinc replacement”

of their hours of operation but of ageing

as well.

The approximate maximum time during

which the chemical-physical characteristi-

cs of a few components or lubricants are

maintained is stated below.

– 1 year – Lubricant oil

– 1 year - Fuel lter cartridge

– 2 years - Cartridges, air and oil lter

– 2 years – Coolant

– 2 years – Transmission belt (type POLY-

V)

Loading...

Loading...