20

Voith Turbo H + L Hydraulic GmbH & Co. KG

25000057510-TED-ENX-04

5 Voith internal gear pumps

This section contains a description of the components and functionality of internal

gear pumps.

5.1 Designandfunctionality

5.1.1Sickleprinciple

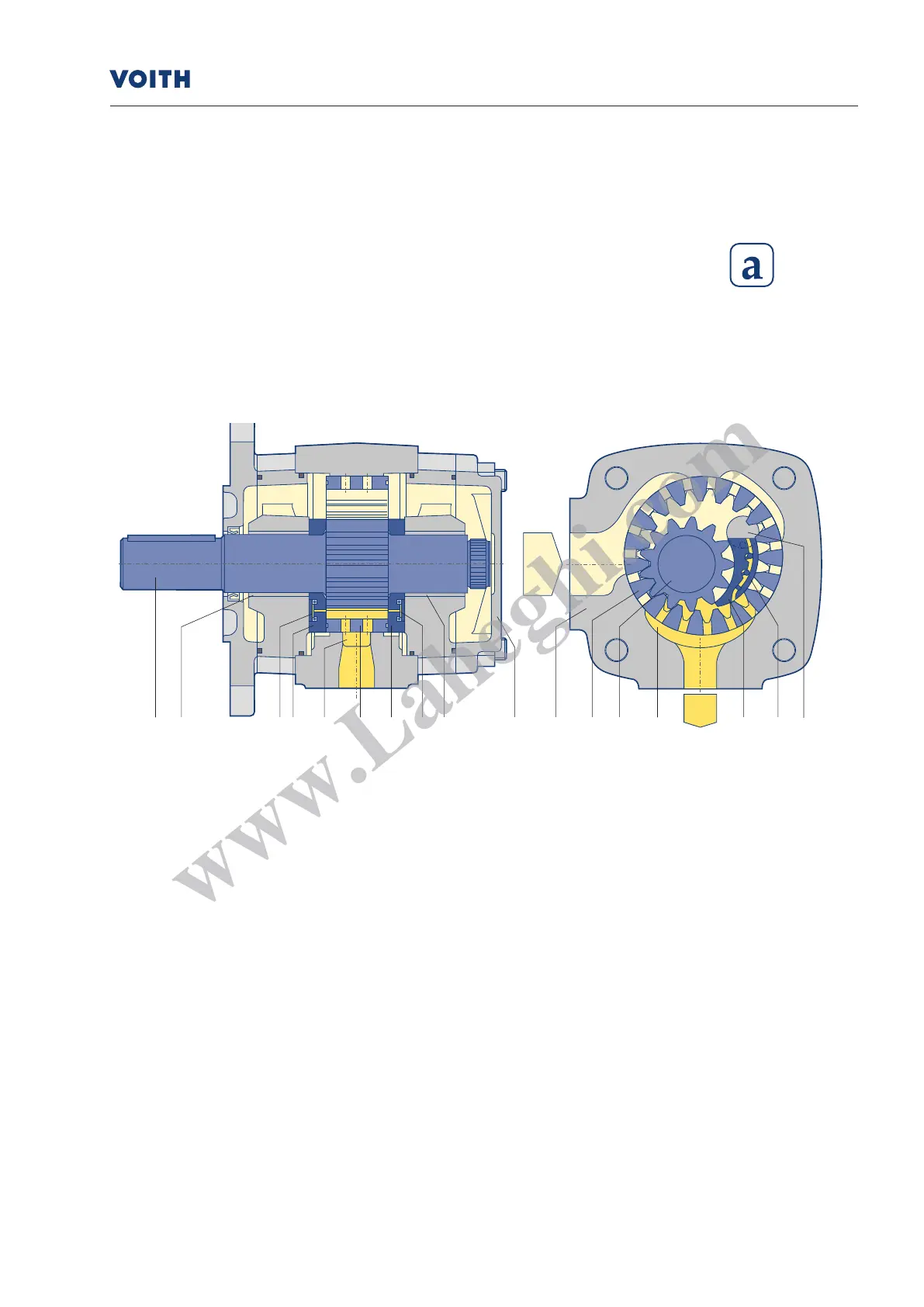

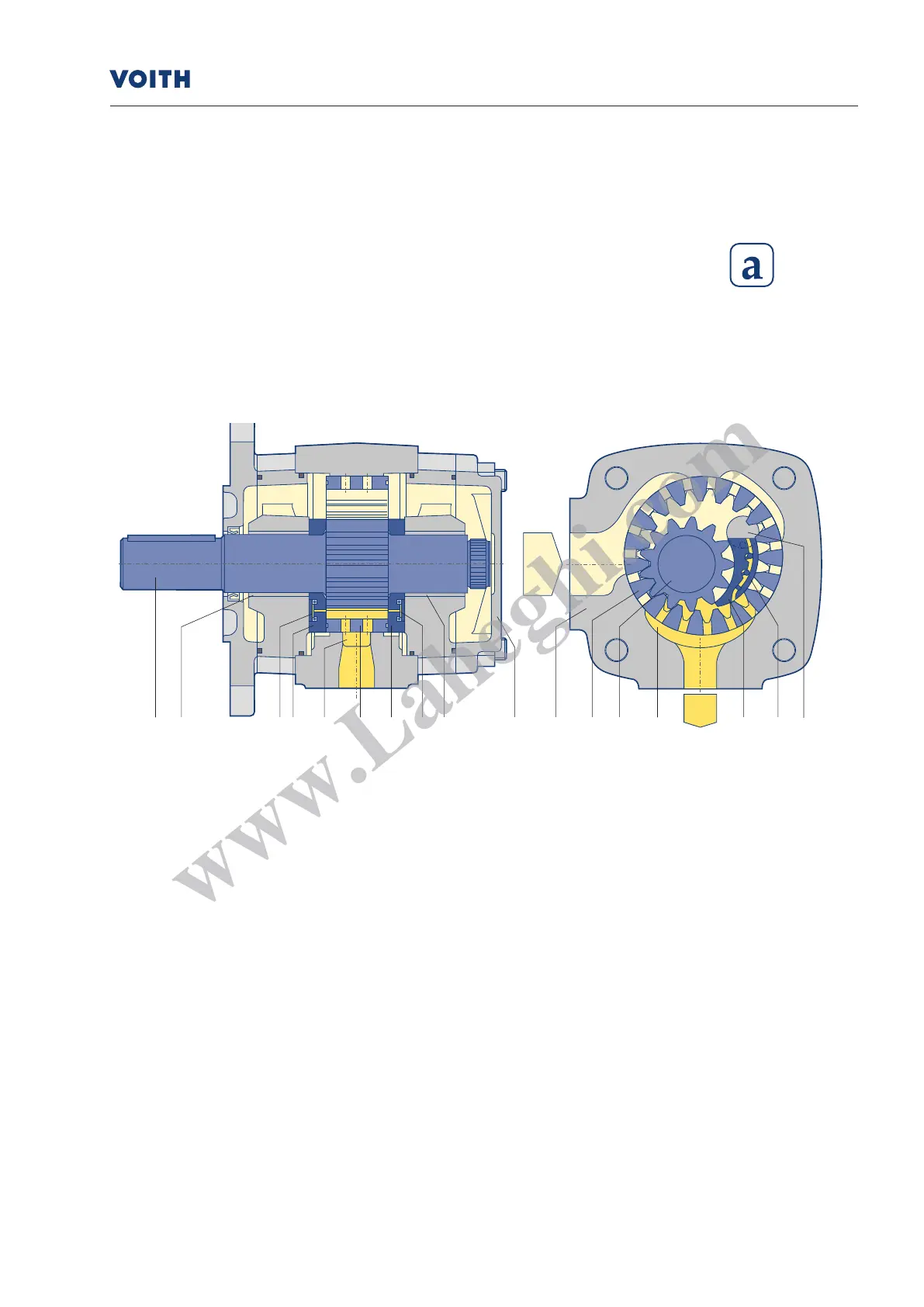

Fig. 5.1.1: Components of internal gear pump with sickle principle

When the gears rotate in the pump the pressure uid (as a rule hydraulic oil) is drawn

into the cavity between the pinion and internal gear. The two smoothly running gears

help to ensure excellent intake behavior.

In the radial direction, the gear chambers are sealed by gear meshing and/or the ller

piece. In the axial direction, the axial plates seal the pressure chamber with the minimal

possible gap. This design minimizes volume losses and increases efciency. When the

gears rotate, the pinion teeth enter the gaps between the internal gear teeth and

displace the pressure uid.

Individual pumps suck via the radial suction port on the pump housing. With two-ow

and multi-ow pumps, suction is generally possible via the suction port on the interim

housing. For low-noise operation of the pumps, the low pump ow and pressure pulsa-

tion usually help.

1 Pinion shaft

2 Internal gear

3 Filler pin

4a Filler segment carrier

4b Filler sealing segment

5 Axial disc

6 Axial pressure area

7 Plain bearings

8 Housing

9 Hydrostatic bearing

10 End cover

1 7 6 5 9 2 5 6 7 10 8 2 1 9 4a 4b 3

Internal gear pumps

Design and functionality

Loading...

Loading...