P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

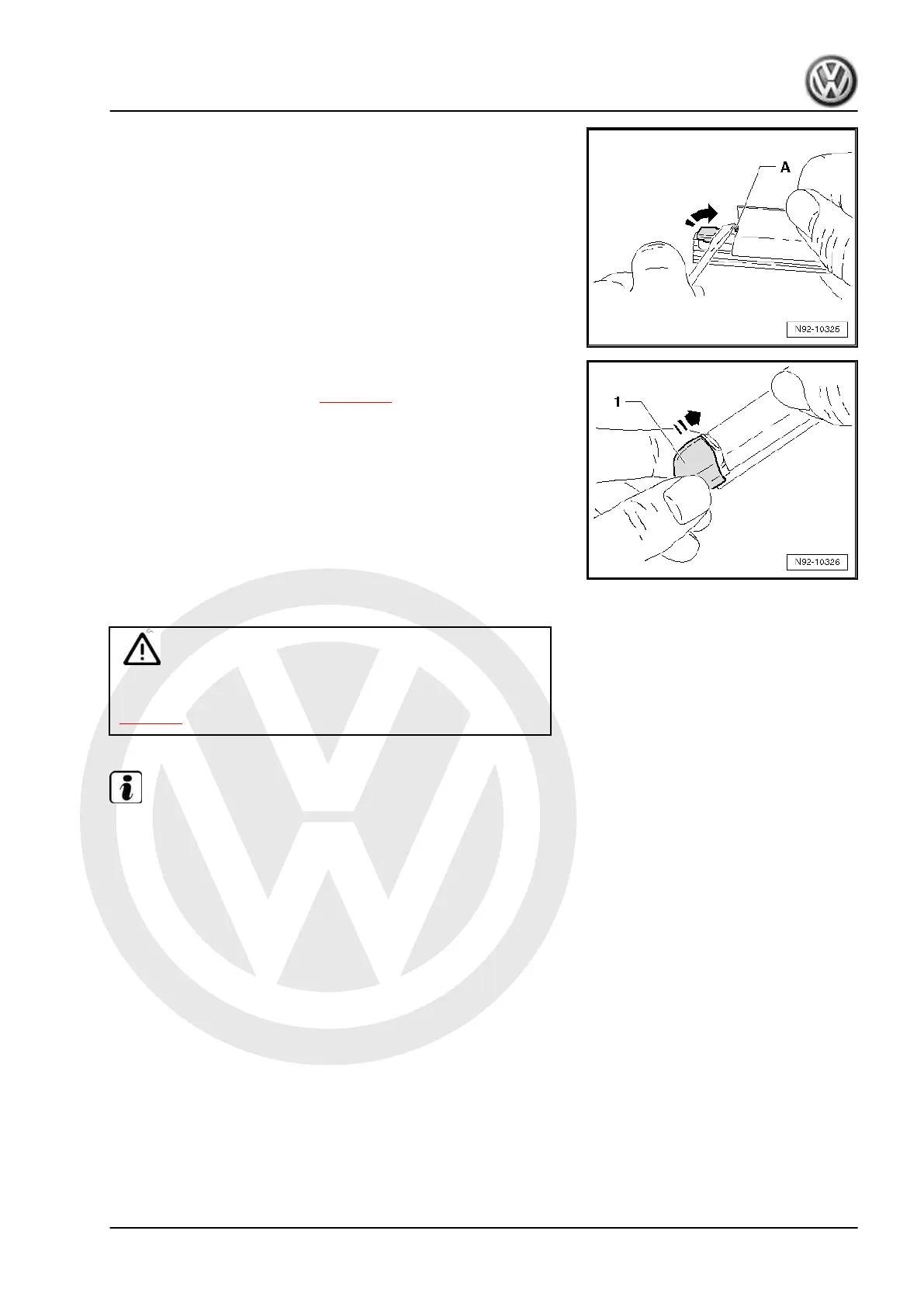

– Push wiper blade stop -A- back down using a suitable screw‐

driver until wiper rubber blade can no longer be moved in the

guide.

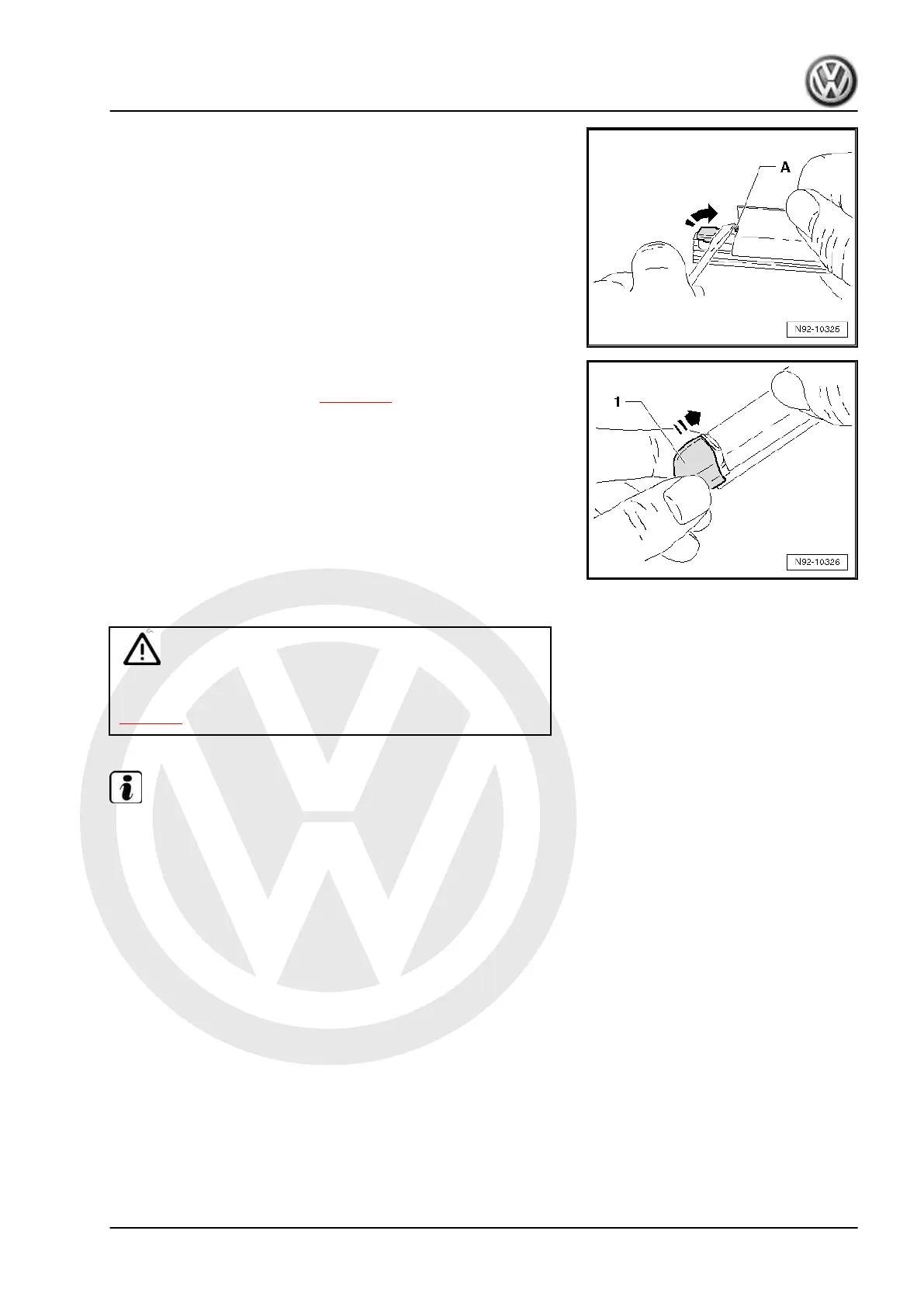

– Fit new cap -1- and check it is seated securely.

– Fit windscreen wiper blade ⇒ page 41 .

– Check wiper blade is working correctly.

1.7 Removing and installing wiper motor - V-

Caution

To disconnect and reconnect the battery, the procedure de‐

scribed in the workshop manual should be strictly adhered to

⇒ page 5 .

Note

♦

The wiper motor control unit - J400- and the wiper motor - -

are combined to form one unit. If the wiper motor control unit

- J400- is renewed, the coding must be read out first and the

new wiper motor control unit - J400- must be code with this

value.

♦

The illustrations show removal and installation of the wind‐

screen wiper system in an LHD vehicle.

♦

Removal and installation of the windscreen wiper system in an

RHD vehicle are analogous.

Special tools and workshop equipment required

up! 2012 ➤

Electrical system - Edition 03.2017

1. windscreen wiper system. 47

Loading...

Loading...