Group 25 Intake and Exhaust System Design and Function

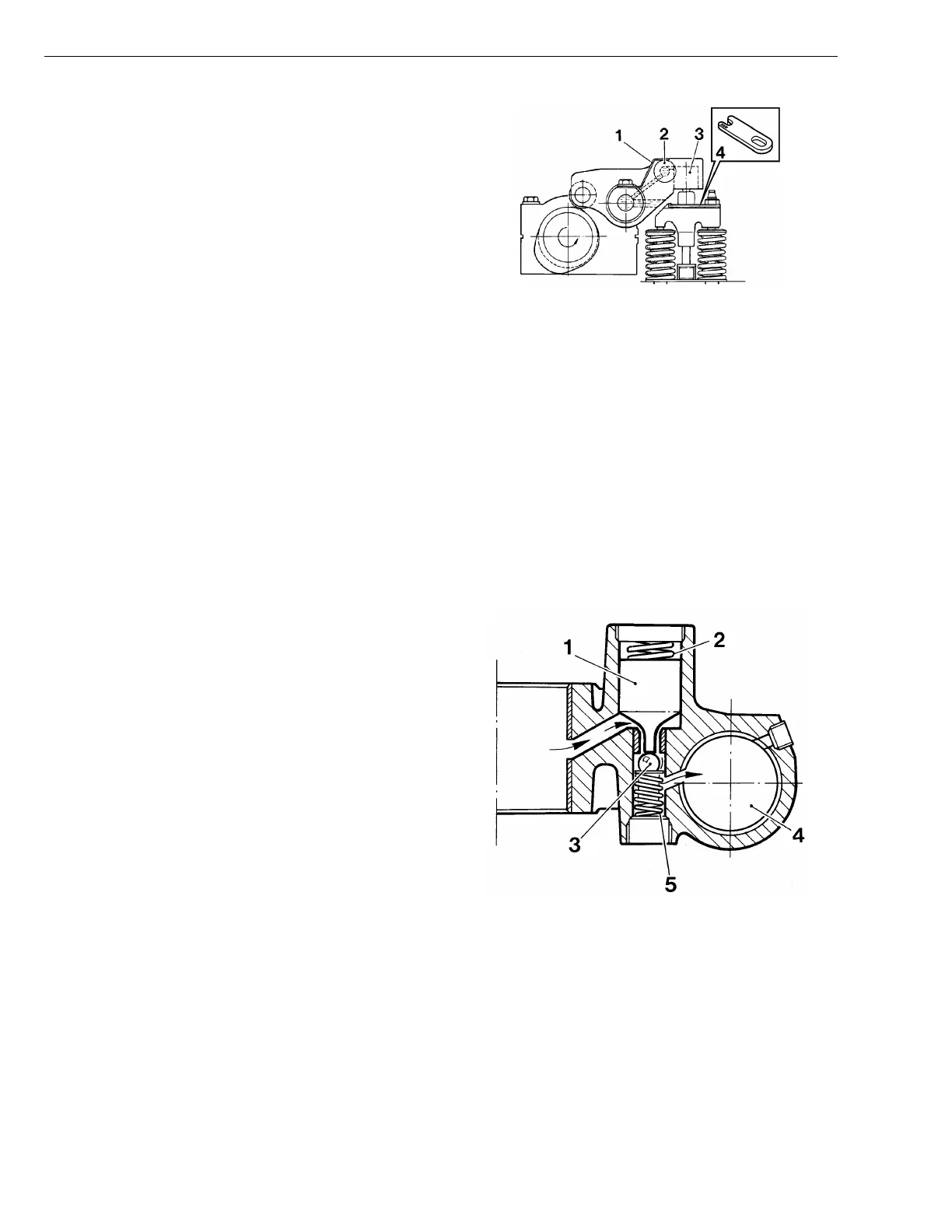

Exhaust Rocker Arms

The exhaust rocker arms on an engine with a compres-

sion brake are larger than those on a conventional

engine.

The rocker arm includes a non-return valve (2) and a

plunger (3) with a pressure limiting valve, the purpose of

which is to regulate the oil flow during compression brak-

ing.

The rocker arm is held in its position against the valve

bridge with the help of a spring tab (1).

The valve clearance is greater than that on an engine

without a compression brake, because the induction and

decompression lobes must not open the exhaust valves

while the engine is in normal operating mode (compres-

sion brake not activated).

Valve adjustment is carried out with shims which are

placed on the valve bridge.

Note: A maximum of two shims are allowed to obtain

proper valve clearance.

W2003502

Fig. 6: Rocker arm assembly, side view:

1 Spring tab

2 Non-return valve

3 Rocker arm plunger

4 Shims

Non-Return Valve

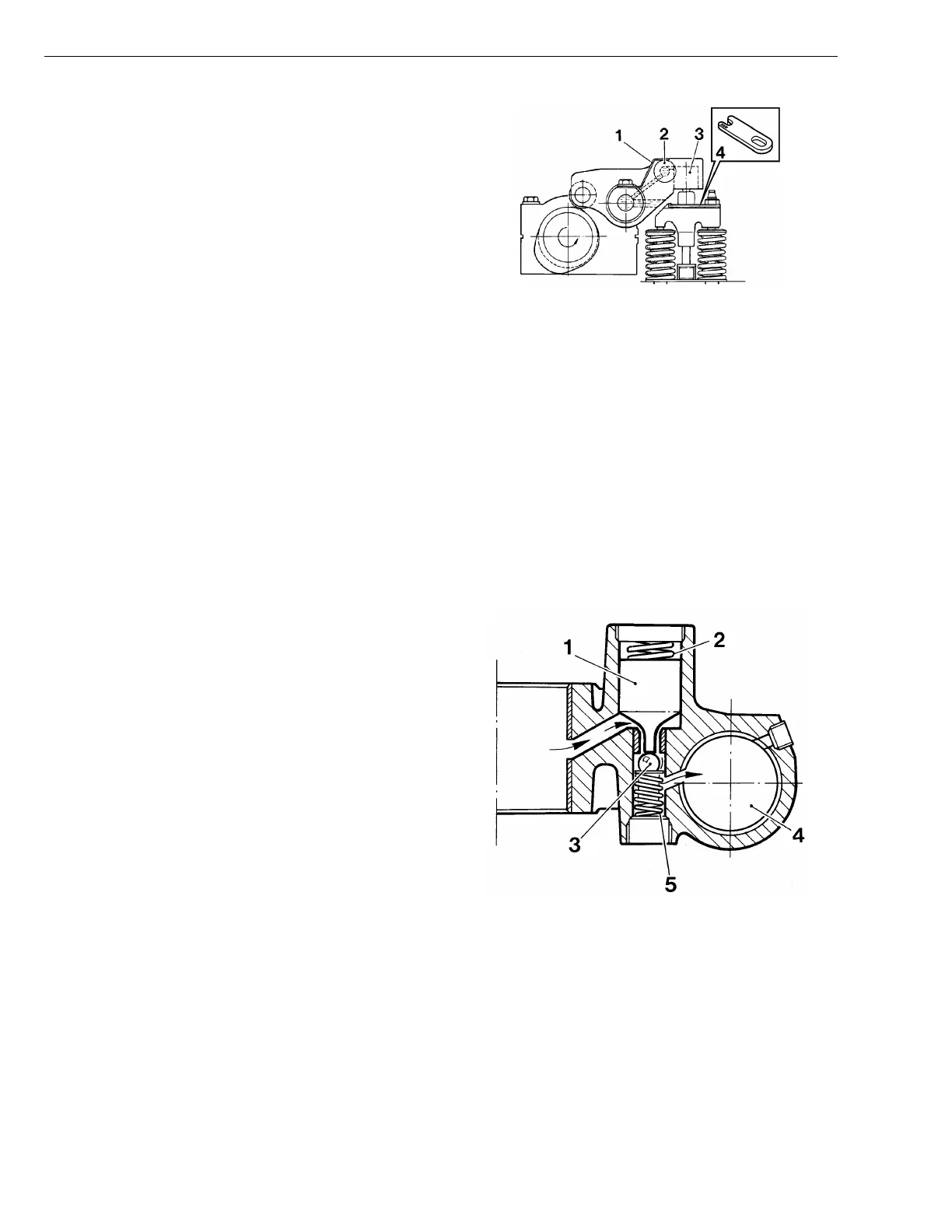

The engine brake has a non-return valve, consisting of a

plunger (1), spring (2) and a ball (3) in the rocker arm.

When oil from the rocker arm shaft enters the valve, the

movement of the plunger is determined by the spring

force and the oil pressure.

When the oil pressure is low — approximately 100 kPa

(14.5 psi); the control valve is in its normal engine oper-

ating position — the plunger (1) will not move out of its

rest position because the oil pressure is not sufficient to

overcome the spring force. The plunger pin prevents the

ball (3) from entering the seating area, and the oil can

then flow freely through the valve in both directions.

When the control valve takes up the position for com-

pression braking, the oil pressure increases to the

non-return valve. The spring force in the non-return valve

is such that when the oil pressure exceeds approxi-

mately 200 kPa (29 psi), the spring force is overcome

and the plunger (1) moves so that it no longer influences

the ball (3). The spring (5) presses the ball (3) against

the seat and prevents the oil contained above the

plunger (4) from flowing past the ball (3). This forms high

oil pressure above the plunger (4).

T2006834

Fig. 7: Rocker arm assembly, top view:

1 Plunger

2 Spring

3 Ball

4 Rocker arm plunger

5 Spring

14

Loading...

Loading...