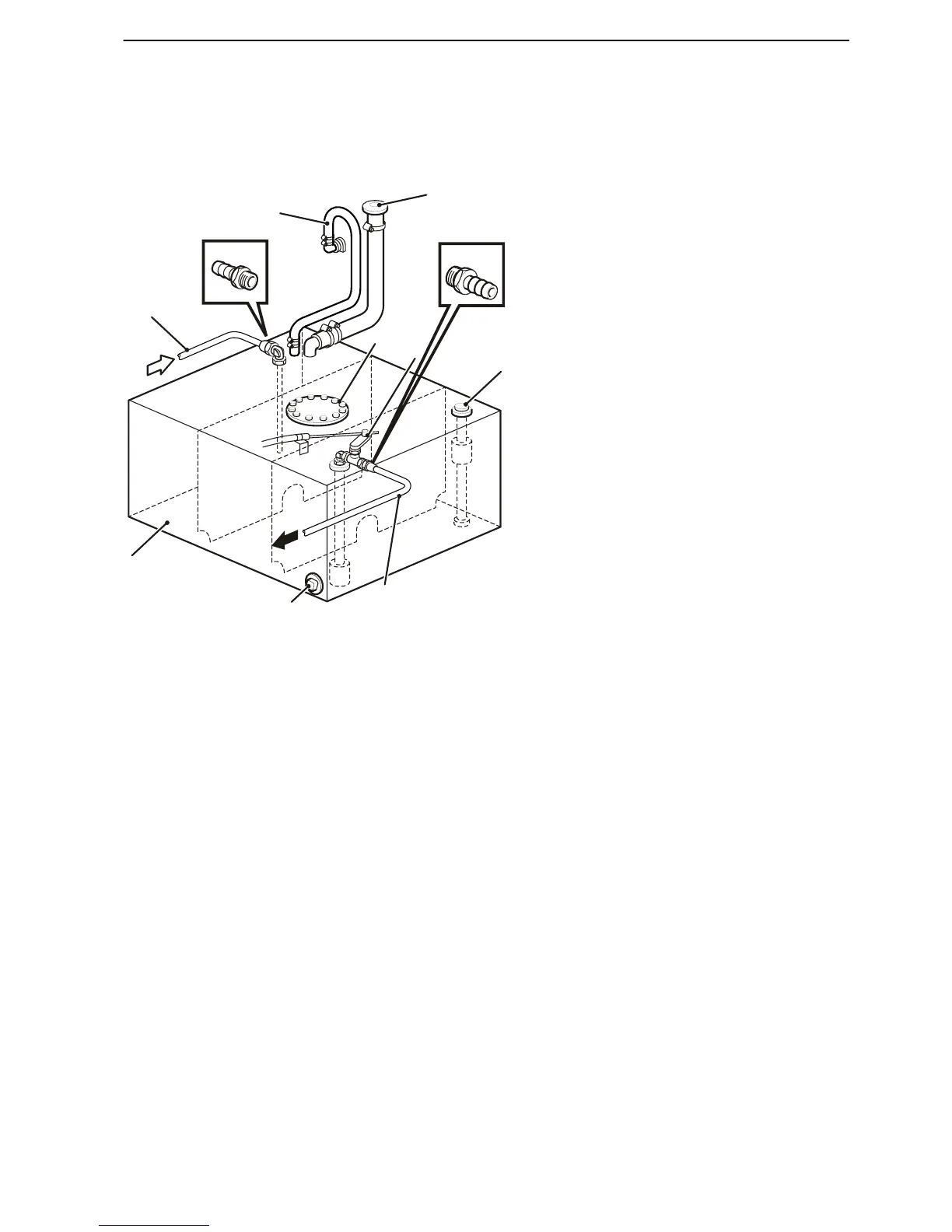

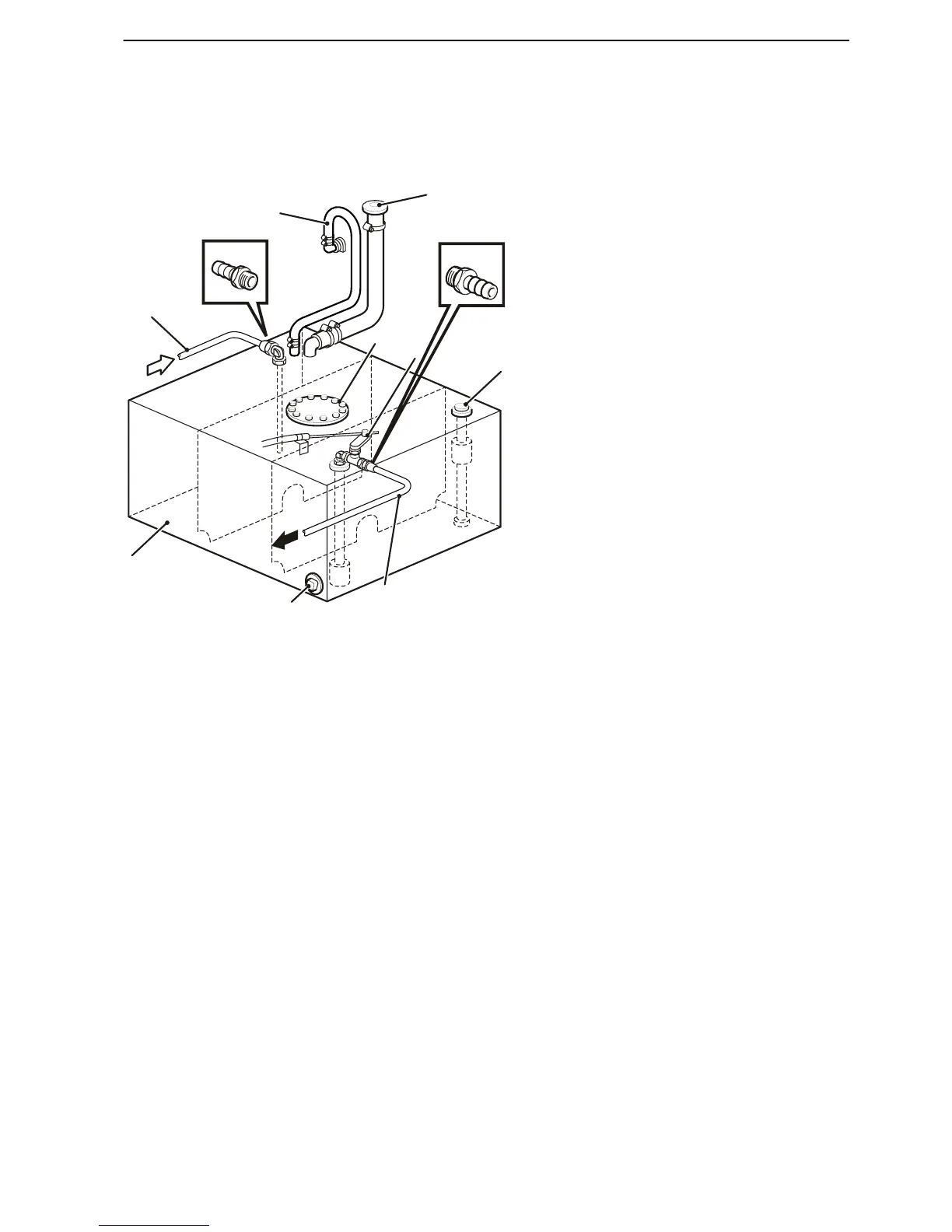

1 Fuel tank

2

Filler cap

3 Vent line

4 Suction line

5 Inspection cover

6 Remotely operated fuel shut-off valve

7 Fuel level sensor

8 Return line

9 Bottom plug

A Nipple in installations with a rubber

hose

The installation of fuel system components such as fuel tank,

taps, fuel pipes and auxiliary fuel filters etc., must be carried

out

very carefully in order to ensure sufficient fuel to the engine

and that the requirements for perfect sealing and fire safety

are met.

Plan the locations of the tanks carefully before starting work.

Use quality taps to avoid leakage. A leaking fuel system

always entails great risk of functional faults and fire.

Use first-class quality components.

Ideally, the taps must be installed on the outside of the engine

compartment, or be remotely operable.

Fuel may be divided up between several tanks in order to keep

the center of gravity low and also to allow adjustment of the

fore-and-aft CoG.

If the tanks are to be built in, the surrounding space must have

good ventilation.

NOTICE! There may be local legislation that

always sets aside engine manufacturer liter-

ature and recommendations.

In Europe, materials and installation of fixed

fuel systems must fulfill the requirements of

ISO 10088. In the USA the installation must

fulfill the requirements of the ABYC and

USCG.

When working on the fuel system, it is impor-

tant to keep it clean and free from dirt.

Installation, Fuel System

47704162 10-2014 © AB VOLVO PENTA 111

Loading...

Loading...