Do you have a question about the WAGNER EPG-SPRINT XE and is the answer not in the manual?

Introduction to the operating manual and its importance for safe operation, maintenance, cleaning, and repair of the device.

Explanation of warning categories (Danger, Warning, Caution, Notice) and symbols used in the manual to indicate hazards and measures.

List of available languages for the operating manual with corresponding order numbers.

Glossary of abbreviations used in the manual, such as Stk, Pos, K, and Order No.

Definitions of key terms used in the manual, including 'Cleaning', 'Flushing', and various staff qualifications.

Specifies the EPG-SPRINT XE as a universal control unit for electrostatic manual and automatic spray guns, intended for type A-P guns.

Details conditions for using the EPG-SPRINT XE in dust explosion zone (Zone 22) according to ATEX requirements.

Outlines safety parameters, reasonably foreseeable misuse scenarios, and WAGNER's liability for incorrect use.

Identifies residual risks that cannot be eliminated even with correct use, including hazards from powder lacquers and cleaning agents.

Explains the ATEX identification markings (CE, 0102, Ex, II, 3(2)D, IP64, 80°C) for the device.

Lists compatible manual and automatic WAGNER powder spray guns that can be connected to the EPG-SPRINT XE.

Details the information found on the device's type plate, including manufacturer, model, voltage, and protection class.

General safety advice for operators, including keeping the manual handy and following local regulations.

Safety requirements for electrical components, maintenance by electricians, and de-energizing before work.

Ensures that only trained persons operate, maintain, and repair the device.

Guidelines for a safe work area, including floor conductivity, footwear, clothing, and ignition source prevention.

Safety instructions for all staff, including warnings about pacemakers and general accident prevention.

Instructions on safely handling spray guns, including not pointing them at people and securing the device during interruptions.

Emphasizes the necessity of proper grounding for the device and work pieces to prevent sparks and ensure safety.

Specifies the use of only original WAGNER powder hoses for safe operation.

Safety precautions for cleaning, including shutting off high voltage, using conductive tanks, and handling flammable liquids.

Guidance on handling powder lacquers, including processing regulations, safety measures, and ventilation requirements.

Instructions on the importance of not tampering with protective equipment and regularly checking its functionality.

Illustrates various safety labels attached to the equipment, such as high voltage, explosive atmosphere, and pacemaker warnings.

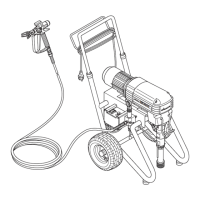

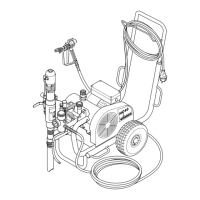

Describes how the EPG-SPRINT XE can be used as a stand-alone unit or within an automatic coating system.

Provides detailed specifications for dimensions, electrical, pneumatic, and ambient conditions of the EPG-SPRINT XE.

Lists accessories that are approved for connection to the EPG-SPRINT XE control unit.

Details the standard equipment included with the EPG-SPRINT XE, such as the unit itself and documentation.

Details illuminated displays for high voltage (0-100 kV) and corona/tribo current (0-5 μA or 0-120 μA).

Describes displays for gun type and buttons for recipe selection, standby mode, and flush functions.

Explains controls for setting total air volume, atomizing/tribo air, and additional air volume.

Details controls for setting high voltage, current limitation, and selecting characteristic curves.

Explains the control for setting and displaying the powder quantity as a percentage.

Diagram and explanation of all connection ports on the rear of the EPG-SPRINT XE control unit.

Emphasizes that commissioning staff must have the necessary technical skills and follow manuals and safety regulations.

Specifies requirements for storing the control unit, including dry location, temperature range, and humidity.

Defines ambient conditions for assembly and commissioning, including temperature and humidity.

Step-by-step guide with diagram for connecting a manual spray gun to the EPG-SPRINT XE.

Diagram and explanation for connecting an automatic spray gun to the EPG-SPRINT XE.

Detailed explanation of grounding requirements for the control unit and work pieces for safety.

Illustrates the grounding procedure for the entire powder coating system, including floors, hooks, and footwear.

Stipulates that operating staff must be qualified and receive appropriate system training before commencing work.

Provides safety instructions related to skin irritation from powders/cleaning agents and compliance with footwear/clothing standards.

Covers initial setup steps including operating modes and gun recognition by the control unit.

Explains the application and function of manual gun mode with external control, including device display feedback.

Describes the factory default configuration for Corona guns and the need to change settings for Tribo guns.

Explains the concept of recipes for storing coating parameters and their selection via recipe buttons.

Details the 'Double Click' function for rapid recipe switching during coating operations via the gun trigger.

Introduces the high output mode achieved by combining feed and atomizing air, dependent on various factors.

Step-by-step guide on how to activate the high output mode (C17) via the device's configuration settings.

Instructions on how to select, change, and save recipes 1-4 using dedicated recipe buttons.

Procedure for indirectly selecting and saving recipes 5-50 using the 'Additional Recipes' button.

General section introducing how to adjust various coating parameters like air volume, powder quantity, and voltage.

Guide on using the 'Total Air Volume' button and rotary controller to adjust air volume from 1-6 m³/h.

Instructions for adjusting the powder quantity from 0-100% using the 'Powder Quantity' button and rotary controller.

Details on setting the additional air volume between 0.05-4.0 m³/h using the 'Additional Air' button.

Procedure for setting the high voltage from 10-100 kV using the 'High-voltage' button and rotary controller.

How to display the currently active high-voltage value during the coating process.

Guide on adjusting the spray current limitation between 5-120 μA using the 'Current Limitation' button.

Procedure to display the actual current limitation value during the coating process.

Explains how to select between three U/I characteristic curves (Standard, Medium, Soft) for optimal results.

Introduction to the two flush functions: Hose Flush and Cleaning Flush.

Describes the hose flush function for blowing air through hoses when powder flow is off.

Explains the cleaning flush function used at the end of shifts or color changes to flush powder-carrying parts.

Step-by-step guide for performing the cleaning flush procedure when using manual guns.

Step-by-step guide for performing the cleaning flush procedure when using automatic guns.

Function to set the powder feed start point, influenced by hose diameter, length, and powder properties.

General information about cleaning work, including hazards and safety instructions.

Specifies that cleaning should be done by qualified and trained staff, who should be informed of specific hazards.

Critical safety warnings regarding explosive powder/air mixes, high voltage, and handling of cleaning liquids.

Guidance on adapting cleaning intervals and adhering to health, safety, and specific instructions for cleaning work.

General information about maintenance work, staff qualifications, and safety instructions.

States that maintenance should be performed by qualified and trained staff, informed of hazards.

Critical warnings about incorrect maintenance/repair, emphasizing qualified personnel and de-energizing the device.

Lists maintenance tasks with recommended intervals (per shift, weekly) for checking various components.

Requirements for testing when used with flammable coating powders, referencing DIN EN 50177 standards.

Requirements for testing when used in manual spray systems with flammable coating powders, referencing DIN EN 50050-2 standards.

Step-by-step procedure for safely disassembling the control unit, including switching off and grounding.

Information on the environmentally correct disposal of used electrical equipment, advising against household refuse disposal.

General safety warnings and requirements for maintenance and repair personnel for troubleshooting.

Lists common warnings (E01-E04) indicated on the LED display, their causes, and remedies.

Details fault codes (E11-E17) indicated on the display, including malfunction, cause, and suggested remedy.

Lists various mains and grounding cables available as accessories, with order numbers.

Details the wall mount accessory for securing the control unit, including its order number.

Describes the recipe label accessory used for documenting settings, including its order number.

Information on how to order spare parts, including required details like order number, designation, and quantity.

Lists spare parts for the EPG-SPRINT XE control unit, including the unit itself and thermal delay fuses.

Manufacturer's liability limited to genuine parts and proper installation, operation, and maintenance.

Details the warranty period and conditions, exclusions for misuse, and procedures for making a warranty claim.

States compliance with EU directives (ATEX, EMC, RoHS, WEEE) and applied standards for the EPG-SPRINT XE.

Official certificate from Physikalisch-Technische Bundesanstalt (PTB) regarding the device's conformity for explosion protection.

Confirmation of approval for the EPG-SPRINT XE control unit in the USA and Canada.

Step-by-step instructions to access and navigate the device's configuration menu.

Explanation of how configuration settings are divided into four groups for different user levels.

Example demonstrating how to set parameter C11 to configure the gun type (Corona, Tribo, or Auto).

Example showing how to activate or deactivate the lock function using parameter C13.

Comprehensive table detailing various configuration parameters (C11-C20), their values, and descriptions.

Overview of the front panel operating elements, identifying buttons, controllers, and displays by number and function.

Instructions on how to select and set individual parameters using the device's selection buttons and rotary controller.

Procedure for selecting, modifying, and saving recipes 1-4 using the dedicated recipe buttons.

Method for selecting, modifying, and saving recipes 5-50 using the 'Additional Recipes' button and rotary controller.

| Brand | WAGNER |

|---|---|

| Model | EPG-SPRINT XE |

| Category | Paint Sprayer |

| Language | English |

Loading...

Loading...