ENCORE

®

700 METERING PUMP

Cleaning Clogged Solution Tube

Where solution joins water being treated and that water contains consid-

erable hardness, there may be a deposit formed inside the solution tube

at the point of application. In time, this can completely plug this tube

and the deposit must be removed. The best method is by dissolving the

deposit as described in paragraph 4.2.1. Where this condition is known

to exist, clean the solution tube as a part of routine maintenance.

Periodic Preventive Maintenance

To minimize unscheduled shut down and ensure maximum service life,

perform periodic maintenance at specified intervals while the equipment

is in satisfactory condition. Table 4.1 lists the intervals, maintenance

operation, and the preventive maintenance kits required. Before starting

the work, ensure that the appropriate preventive maintenance kits are in

stock. Refer to Section 6 - Preventive Maintenance Kits and Spare Parts

List for the appropriate maintenance kit.

NOTE: Although all parts are designed for long service life, it is rec-

ommended that routine maintenance be performed to safeguard

against unexpected downtime.

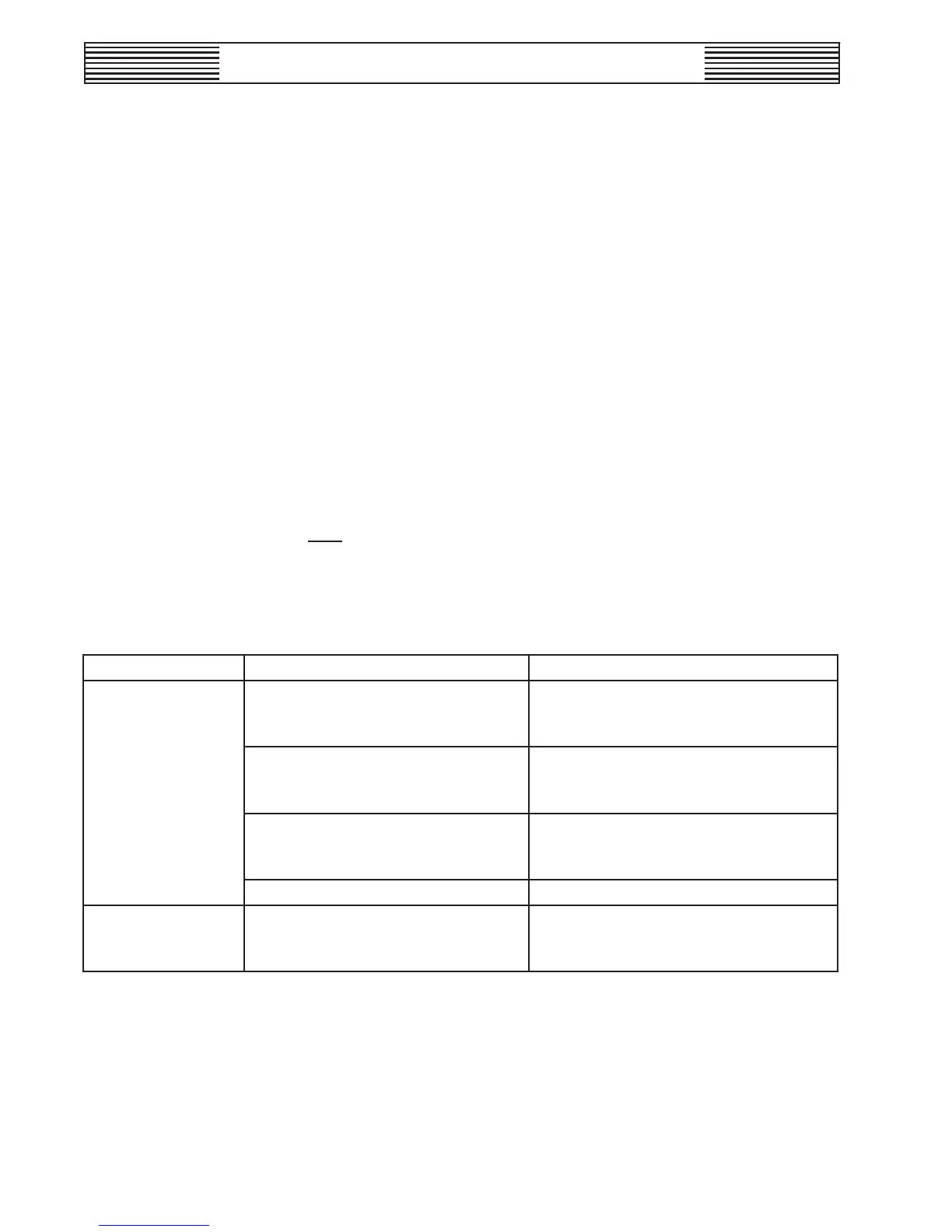

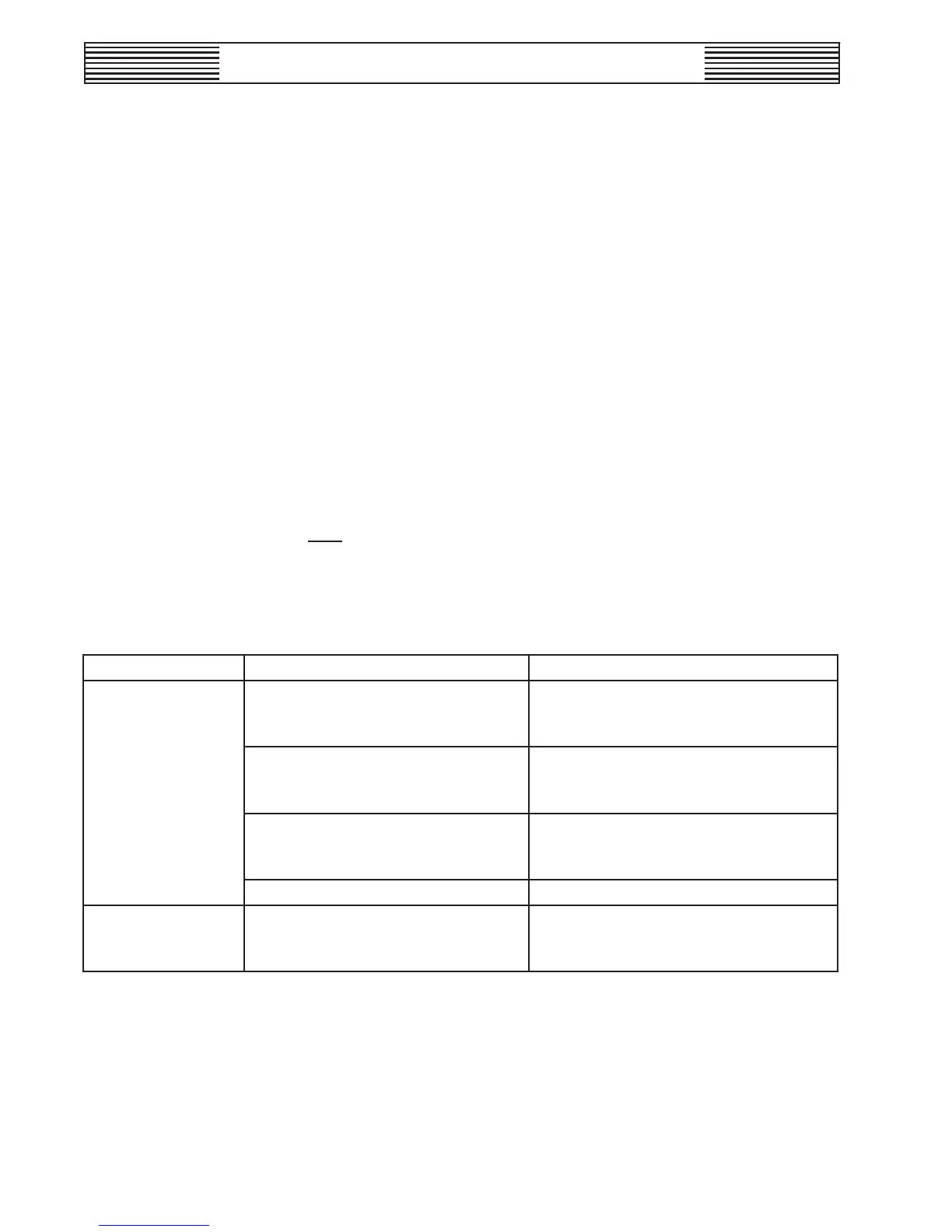

Table 4.1 - Scheduled Maintenance Index

Preventive Maintenance Kit

Annually

Replace PTFE diaphragm, PTFE disc

(between diaphragm and back-up

ring), and crosshead bellow seal.

Diaphragm Maintenance Kit

Replace valve sets, which include

the seat, ball, retainer/guide, and

Valve Kit

(Double ball valves: 2 kits required)

Lubricate (refer to paragraph 4.3.1).

Food-grade synthetic oil AAA5499

(W2T10431) (optional)

SAE85W90 Mineral Gear Oil (2 qts)

Six Months

For slurry application or other

abrasive chemical, replace valve

sets every six months.

Valve Kit

(Double ball valves: 2 kits required)

WT.440.400.001.UA.IM.1012

33

Loading...

Loading...