Thermo Top Evo 8Servicing work

801

8Servicing work

This section describes the servicing work that can be carried

out on the heater and its components while installed.

8.1 Work on the heater

The power supply must always be disconnected at the vehi-

cle battery before carrying out any work on the heater. The

power supply must not be disconnected whilst the heater is

operating or slowing down as a result of the risk of the

heater overheating and the overheating protection thus

being tripped. If repair work is carried out on the heater, it

must be completely removed. After the heater and all cool-

ant-carrying components have been installed, the entire

coolant system must be filled, bled and checked for leaks

with the specified system pressure in accordance with the

vehicle manufacturer's instructions. The general installation

instructions and the vehicle-specific installation instructions

for the heater must be observed when carrying out repairs

which make it necessary to change the installation location.

NOTE

Any coolant running off should be collected using an appro-

priate container.

8.2 CO

2

setting

NOTE

After repairing the heater and/or replacing the metering

pump, the setting of the CO

2

value should be checked.

IMPORTANT

After replacing the fan unit or the control unit, the CO

2

value must be checked and reset if necessary.

The CO

2

setting is carried out with Webasto Thermo Test PC

Diagnosis.

The heater is optimally set to a CO

2

value for operation at

altitudes between 0 and 1,000 m above sea level at the fac-

tory. Continuous operation above 1,000 m above sea level

can lead to heavy smoking and formation of soot.

To prevent a failure of the unit and danger, the CO

2

value

should be adjusted in consultation with Webasto.

NOTE

The CO

2

measurement and setting must be carried out in

the full load heater operating mode (display in Webasto

Thermo Test: Full Load). The CO

2

value is corrected in selec-

tion point 2.7.1. CO

2

calibration of Webasto Thermo Test

PC Diagnosis. The measurement of the CO

2

content is car-

ried out approx. 20 mm in front of the end of the exhaust

outlet inside the exhaust pipe with a CO

2

tester (e.g. from

MSI).

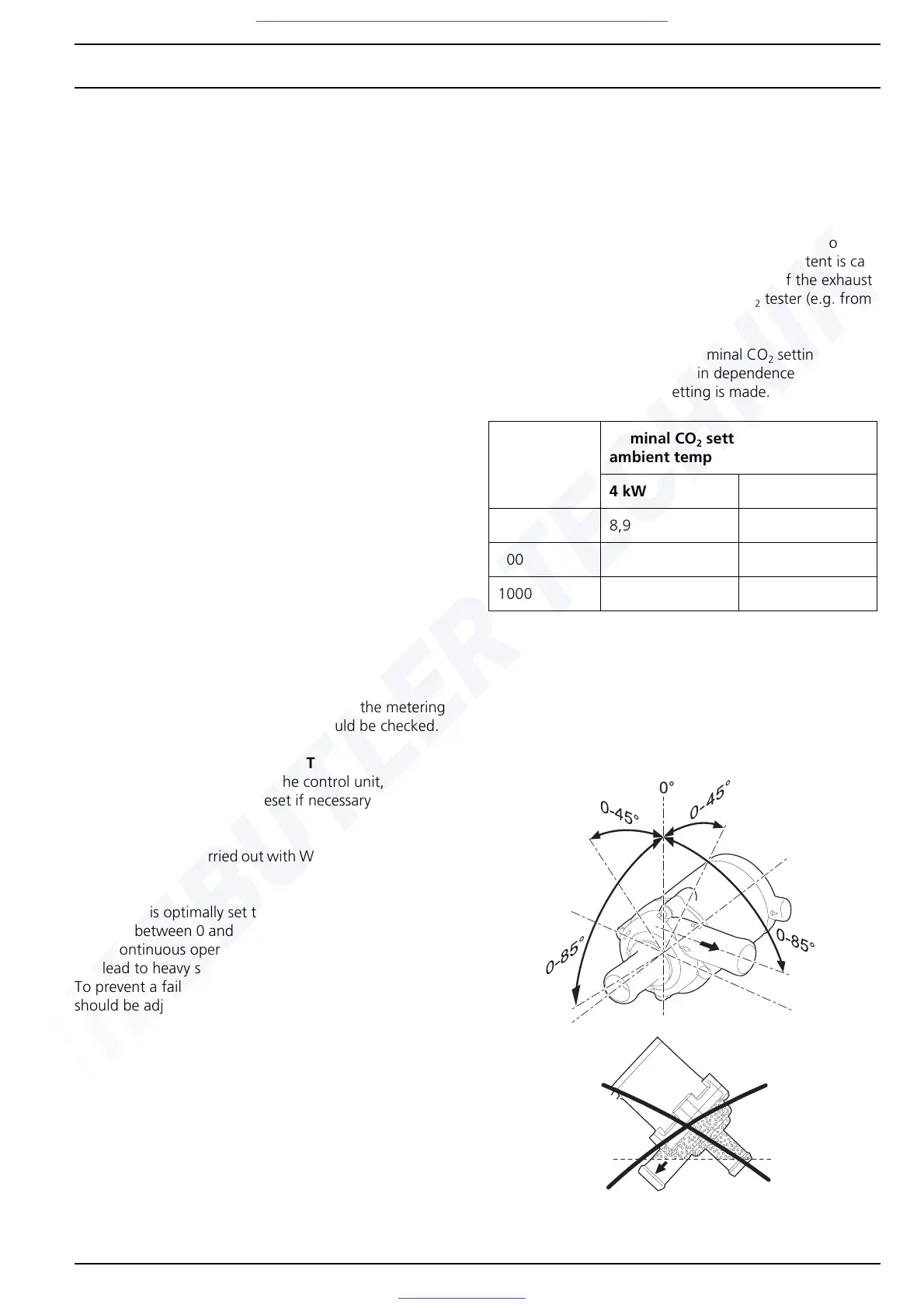

The following table shows the nominal CO

2

setting value in

full-load combustion operation in dependence on the geo-

detic altitude at which the setting is made.

8.3 Circulating pump

The power consumption is approx. 12 W with a nominal

volume flow rate of 450 l/h.

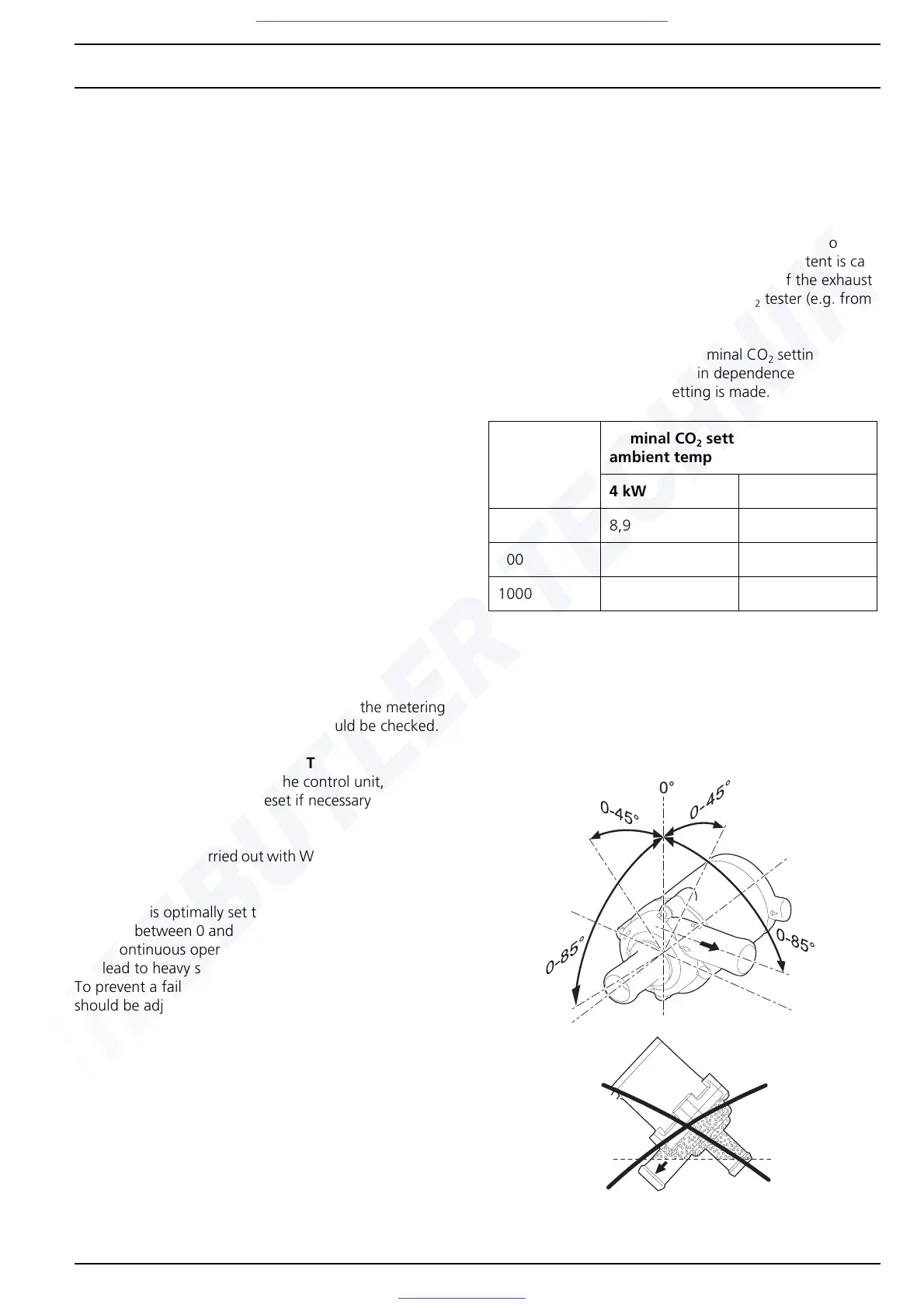

Fig. 802 Installation position of U4847 Econ circulating

pump

Altitude

[m above

sea level]

Nominal CO

2

setting value at 20 °C

ambient temperature [% by vol.]

4kW 5kW

0 8,9 9,5

500 9,5 10,1

1000 10,0 10,7

Fig. 801 CO

2

setting values

Visit www.butlertechnik.com for more technical information and downloads.

Loading...

Loading...