23

During operation, coolant level must be between the low and high marks of the

tank level.

If there is no coolant in emergencies, slowly add coolant with temperature not too

lower from the coolant ller, until the coolant becomes over-own. Start engine and

continue to add coolant with engine running at 1000 r/min, till it is full and the level

becomes stable. Finally cover the ller cap.

4.4.5 Monitoring the exhaust gas

Healthy engine operation and performance can be properly pointed out by

the engine exhaust. Poor mechanical adjustments, dirty air cleaner, using

poor grade fuel or over-fueling may cause a smoky exhaust. Action should

be taken immediately to treat it. If any serious color change is noticed, stop

the engine and carry out the inspection procedure. Refer table 4.3 for main

parameters of analyzing the exhaust gas.

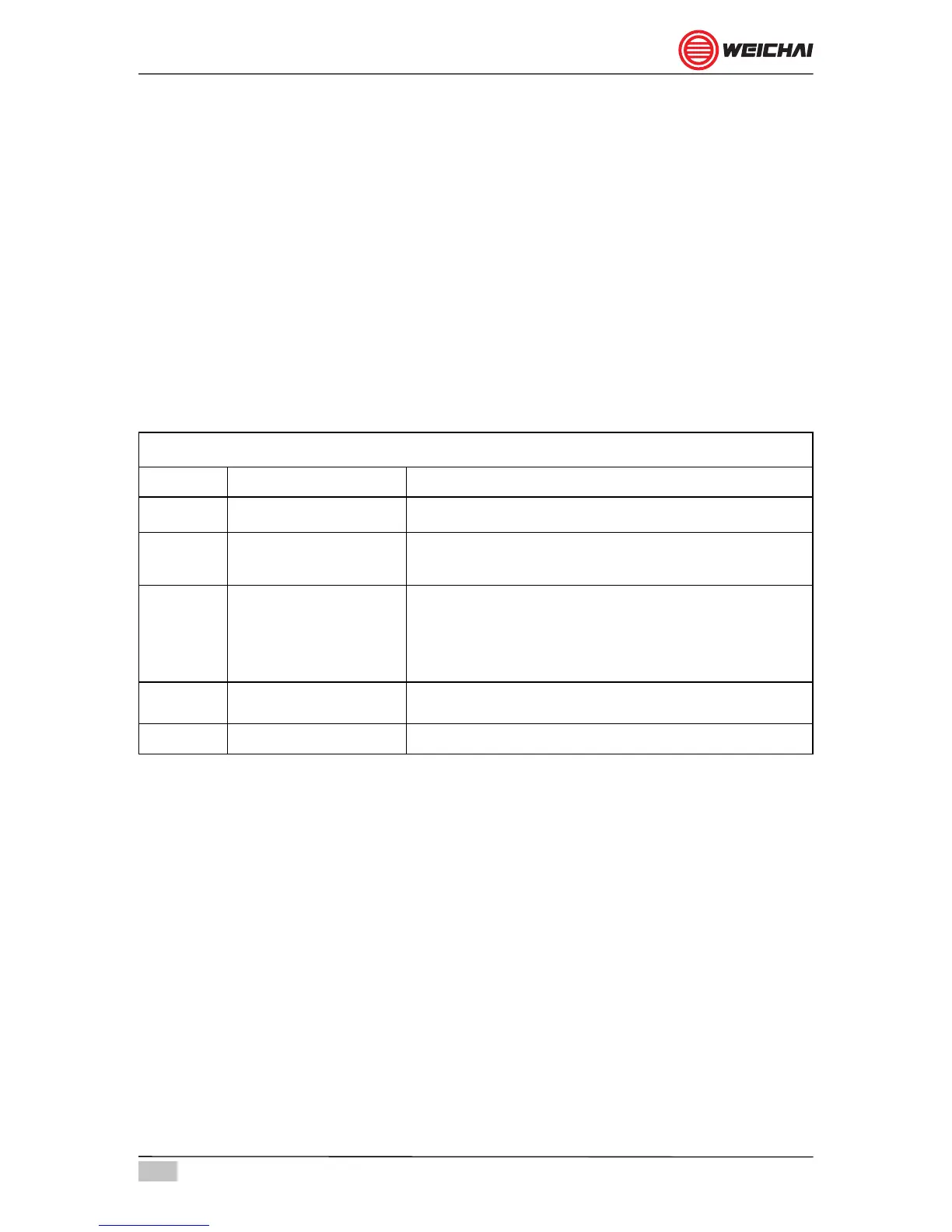

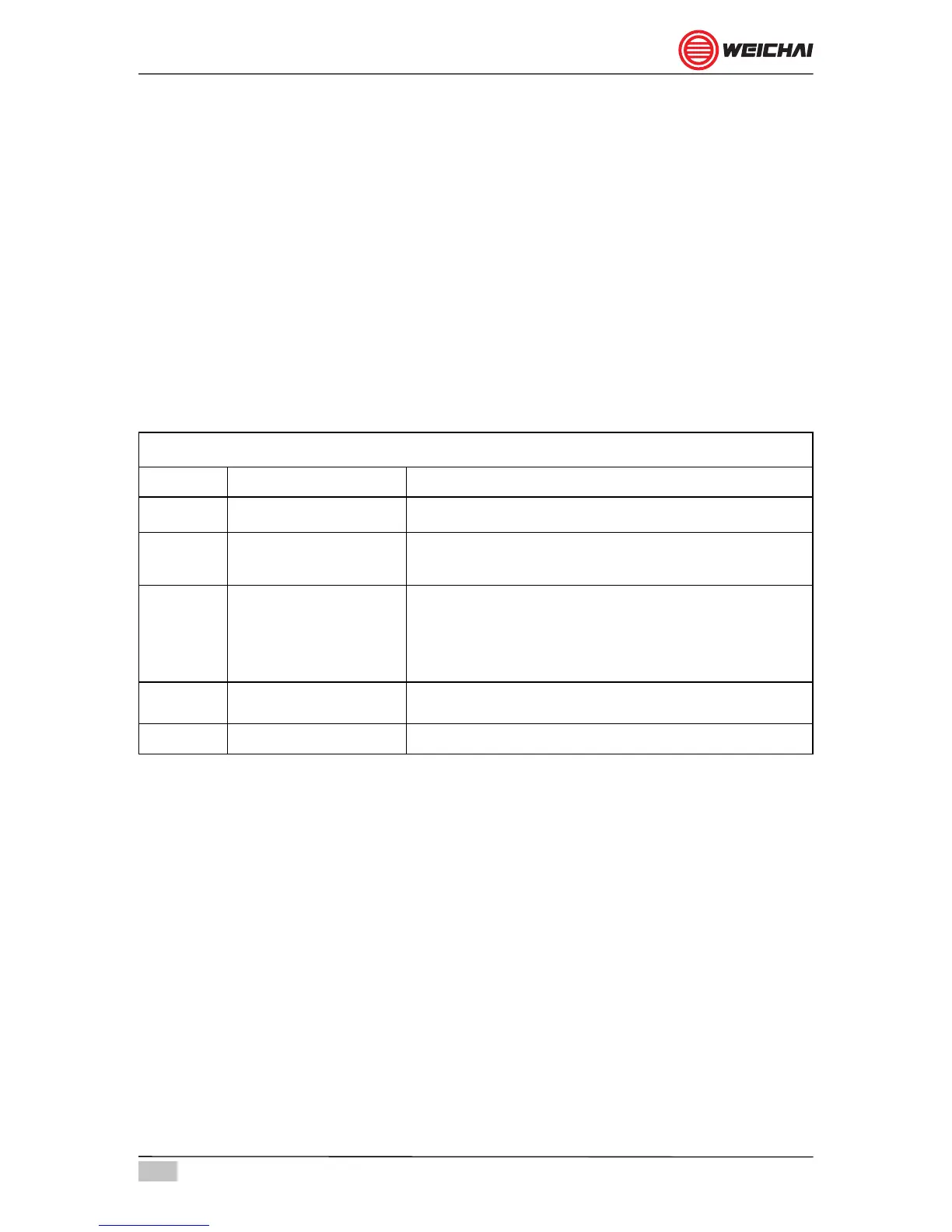

EXHAUST GAS QUALITY MONITORING

SR.NO COLOR REASON

1 Clear Healthy combustion system

2 Grey

Poor combustion quality (faulty injector or

injection pump, weak compression, etc.)

3 Dark grey

Poor combustion quality (one or more system

failed - choked air lter, weak turbocharger,

chocked intercooler, failed injector or fuel

injection pump etc.)

4 Blue Engine oil burning in combusting chamber

5 White Water ingresses in fuel/combustion system

Table 4.3

4.4.6 Engine shutdown

Engine should run on idle speed for 3~4 minutes before shutting down. Running

on idle speed will ensure uniform heat dissipation and enough cooling and to

lubrication to high temperature areas like turbocharger & combustion chamber etc.

However excessive idling should be avoided.

Caution for operation

After starting the engine, let it run at idle speed for a few minutes (2-3 minutes),

then gradually increase the speed to 1000~1200r/min, and apply a partial load.

Apply full load only when the fresh water outlet temperature is higher than 60°C,

and oil temperature is higher than 50°C. Increase the load and speed gradually.

Avoid sudden application or removal of load.

Loading...

Loading...