30

5.7.2 Cleaning air lter

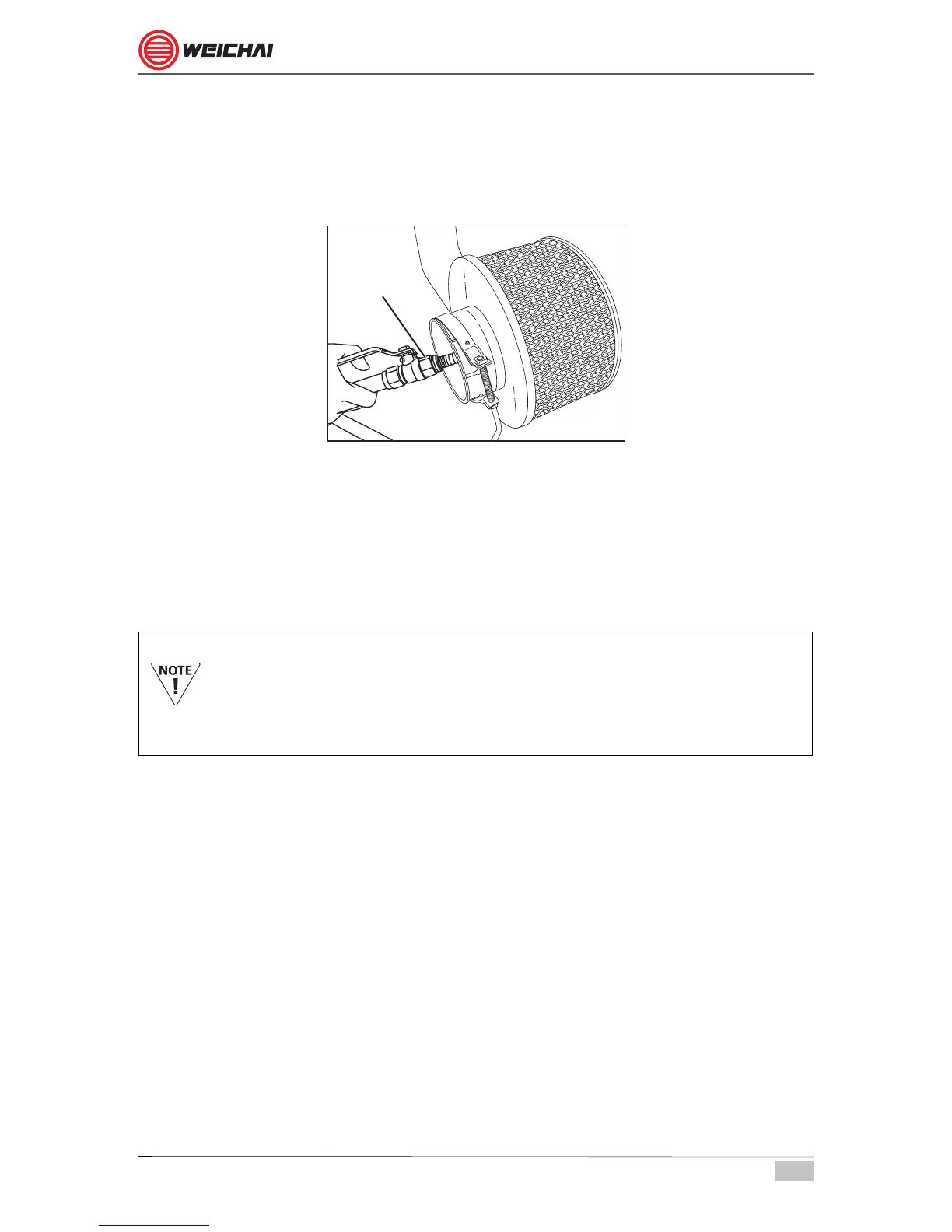

Always use clean and dry air to clean the air lter element. The air pressure should

not exceed 600 Kpa. To make cleaning process more efcient, always direct the

compressed air from inside to outside the element. Don’t clean the air lter with

diesel or water. (Refer gure 5.1).

compresed air

(<600 kPa)

Figure 5.1

5.7.3 Replacement of engine oil

Generally, the oil and oil lter are required to be replaced at the same time. The oil

shall be replaced at the time when engine is stopped after operating for a period of

time and oil temperature of engine is a little lower than the operating temperature.

When replacing the oil, loosen and remove the drain plug provided on the side of

the oil sump.

After the engine oil is drained off completely, carefully inspect

the magnetic part of the drain plug for accumulation of metal

particles. Accumulation of various metal particles is the indication

of abnormal wear of internal components. Carry out the inspection

before proceeding to the next step.

Wipe, clean the drain plug and re tighten it to oil sump. Add fresh oil from oil lling

port as per required quantity of the specied grade. Start the engine and run it for

a short time. Check the oil level, top up if required.

Precautions

• Never run an engine without oil.

• Do not run an engine with oil ller port open or oil dipstick taken out.

Loading...

Loading...