7

SECTION – III

INSTALLATION GUIDELINES FOR ENGINES AND ACCESSORIES

3.1 De-preservation of new engine

After the engine packing crate is unpacked, carry out the pre-commissioning

inspection (PCI). Make sure engine and the sub parts supplied are as per the

purchase order, free from defects and all material supplied are as per the packing

list.

1. Wipe off the anti-rust coat, anti-corrosion agent, from the exposed parts such as

turbocharger, ywheel etc.

2. Drain preservation oil from the engine sump.

3. Inject sufcient lubricant to turbocharger lubrication line to ensure proper

lubrication during startup.

The preservation period of diesel engine is six months. When

the storage/ idle duration exceeds six months, conduct

inspection and adopt necessary supplementary measures as

per company recommendations.

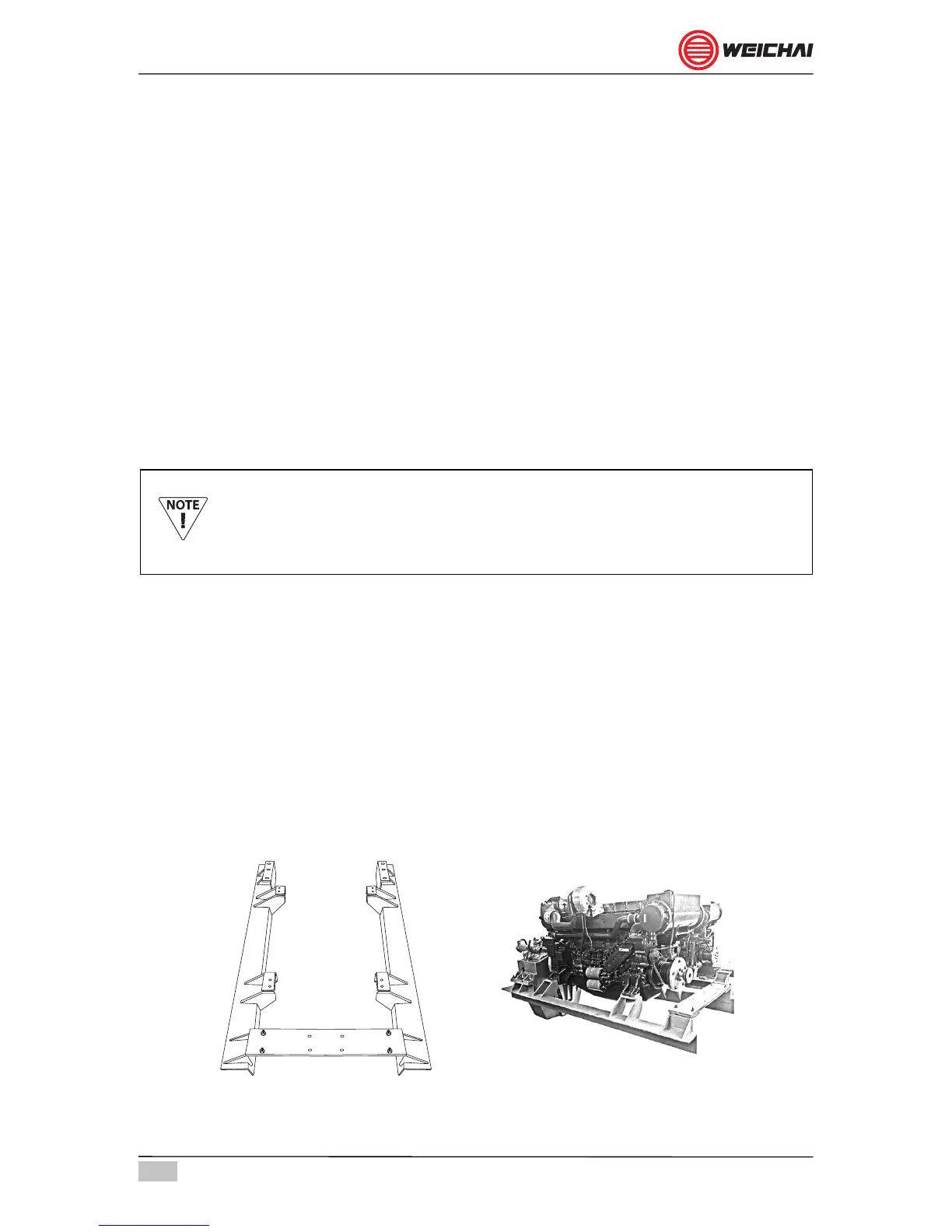

3.2 Engine installation procedure

WP12 series marine diesel engine is assembled with SAE-I ywheel and ywheel

housing. Select the gear box and coupling accordingly. When installing the engine,

ensure the axial and radial alignment of engine crankshaft is linearly arranged with

the gear box input shaft. Dimensions from diesel engine-mounting bracket plane to

crankshaft centerline will be varying for different engine models. Fabricate / select

the correct base-frame according to the engine model (Refer gure 2.1 & 2.2).

It is advised to couple the diesel engine with gear box by using suitable elastic

coupling. After coupling the engine with gear box, no axial force is allowed to act

on the diesel engine crankshaft; otherwise it will lead to failure and damages of

engine’s major sub-assemblies.

Figure 3.1 Figure 3.2

Loading...

Loading...