4.4 Burner installation

Preparing the heat exchanger

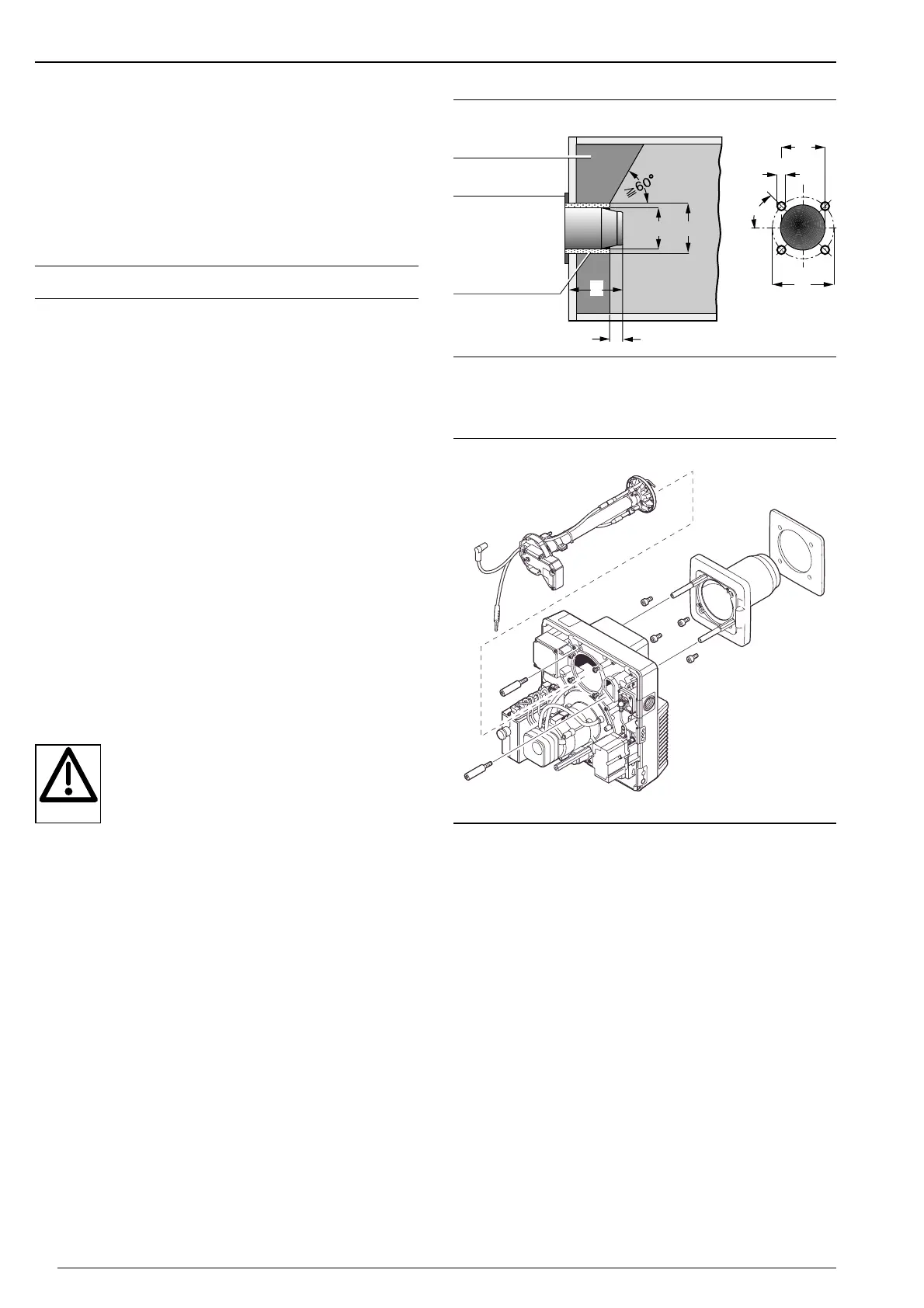

The diagram shows the refractory for a heating appliance

without cooled front. The refractory can, however, take a

conical shape (≥ 60°). Refractory may not be required on

boilers with water-cooled fronts, unless the manufacturer

gives other instructions. The front edge of the combustion

head should, as a minimum be flush with the refractory, or

protrude a maximum of 30mm.

Comb. Dims in mm

head d

1 d2 d3 d4 d5 l1

WG10-C 120 M8 150-170 130 135 140

** Depending on type of heat exchanger.

See manufacturers information!

The gap between

combustion head

and refractory must

be filled with

resilient, non-

combustible

insulating material.

Do not make solid.

Heat exchanger

drilling dims.

Refractory

Flange gasket

Refractory and drilling dimensions

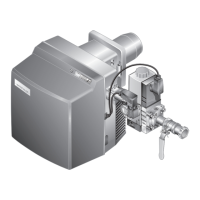

Burner installationBurner mounting

1. Remove mixing head ➄ (see Ch. 7.3)

2. Remove screws ➃.

3. Separate burner flange ➁ with flame tube from housing.

4. Fix burner flange with screws ➂ to the boiler plate.

5. Place burner housing onto stay bolts ➅.

6. Fit screws ➃ and tighten.

7. Check setting of ignition and ionisation electrodes (see

Ch. 7.5).

8. Refit mixing head (see Ch. 7.3)

Ensuring that the gas-canal gasket is located correctly.

Fitting burner rotated by 180°

For valve trains fitted from the left, the burner can be

rotated by 180°. No other conversion work is required.

➀ Flange gasket

➁ Burner flange

➂ Hexagonal screw

➃ Hexagonal screw

➄ Mixing head

➅ Stay bolt

Danger of getting burnt

Some burner parts (e.g. flame tube, burner

flange, etc.) become hot during burner

operation and should be allowed to cool prior

to service work being carried out.

Loading...

Loading...