4.6 Soundness test of valve train

❏ The valve train soundness test must be carried out with

the ball valve and solenoid valves closed.

Test pressure in valve train: _____________ min. 100 mbar

Waiting time for pressure equalisation: _______ 5 minutes

Test time: ________________________________ 5 minutes

Max. permissible pressure drop: _______________ 1 mbar

(gas train design pressure _____________ max. 500 mbar)

First test phase:

Ball valve up to first valve seat

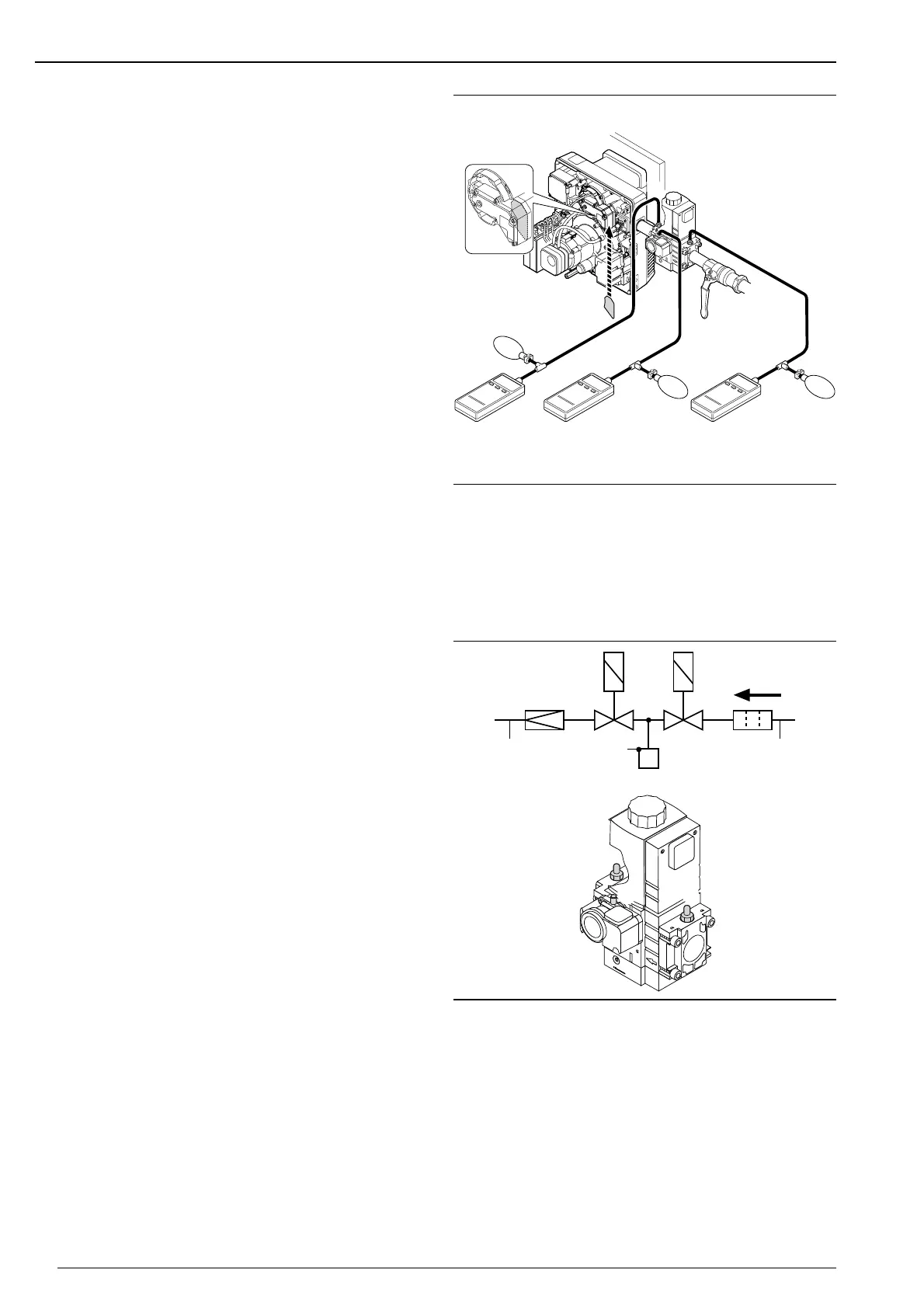

1. Connect test assembly to test point ➊.

2. Open test point ➋.

Second test phase:

Between the valves and second valve seat

1. Connect test assembly to test point ➋.

2. Open test point ➌.

Third test phase:

Valve train connection parts and gas butterfly valve

1. Fit blanking plate ➀.

(see notes Ch. 7.3)

2. Fit measuring device to test point ➌.

3. Remove blanking plate ➀ once soundness test is

complete.

4. Tighten Torx screws on mixing head.

Note: To carry out an external soundness test, brush

connection points with foam forming agents or

similar, non-corrosive material, or use an

electronic gas detector.

Soundness test

1

st

Test

phase

2

nd

Test

phase

3

rd

Test

phase

➀ Blanking plate

➁ Measuring device (U tube or manometer)

➂ Manual pump

➃ Hose clamp

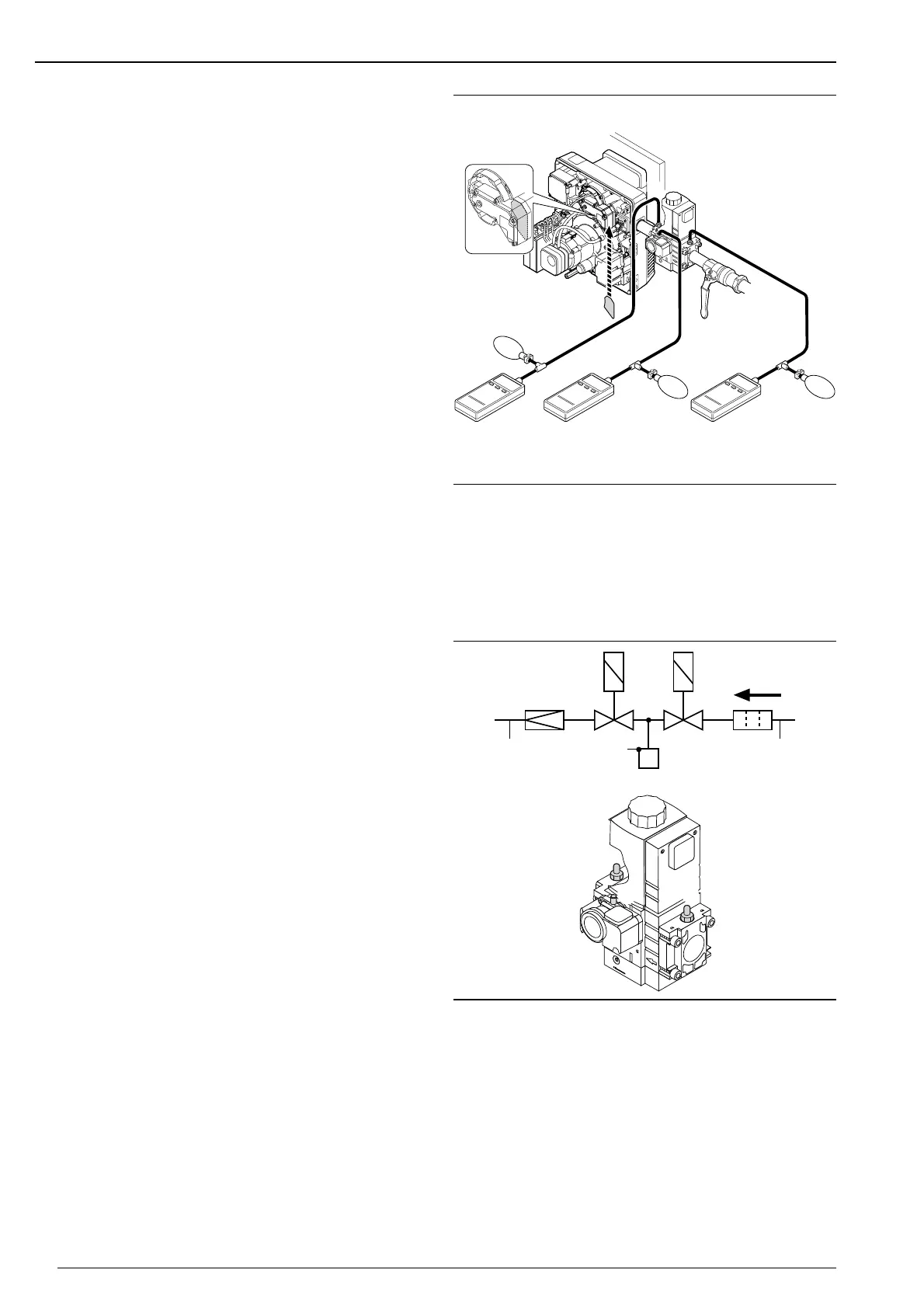

Test points on W-MF 507

Test point ➊: Pressure into filter (inlet)

Test point ➋: Pressure between V1 and V2

Test point ➌: Gas pressure setting

Test points on multifunction assembly

For the soundness test, the test points must be opened by

loosening the screw in the test nipple.

☞ Close all test points once the soundness test is

completed!

Documentation

☞ The results of the soundness test must be documented

in the service report.

Loading...

Loading...