11

4.5 Valve train installation

Risk of explosion!

Gas leaks can lead to the build-up of explosive

gas/air mixtures. With the presence of an

ignition source, these then result in

explosions.

To avoid accidents, please follow the following safety

instructions on valve train installation.

☞ Before beginning work, close all the relevant shut off

devices and ensure they cannot be accidentally

reopened.

☞ Ensure the valve train components are correctly

aligned and that all the joints are clean.

☞ Flange seals must be fitted correctly on the machined

faces.

☞ Tighten screws evenly diagonally opposite.

☞ Valve trains must be mounted tension-free.

Do not compensate for misalignment by over-

tightening.

Do not tighten or seal pipe thread connections while

mounted on the burner.

☞ The valve trains must be fixed and supported securely.

They must not be allowed to vibrate during operation.

Supports suitable for the site should be fitted during

installation.

☞ Only sealing agents tested and approved by the gas

supplier must be used.

The double nipples supplied have already been coated

with an approved substance.

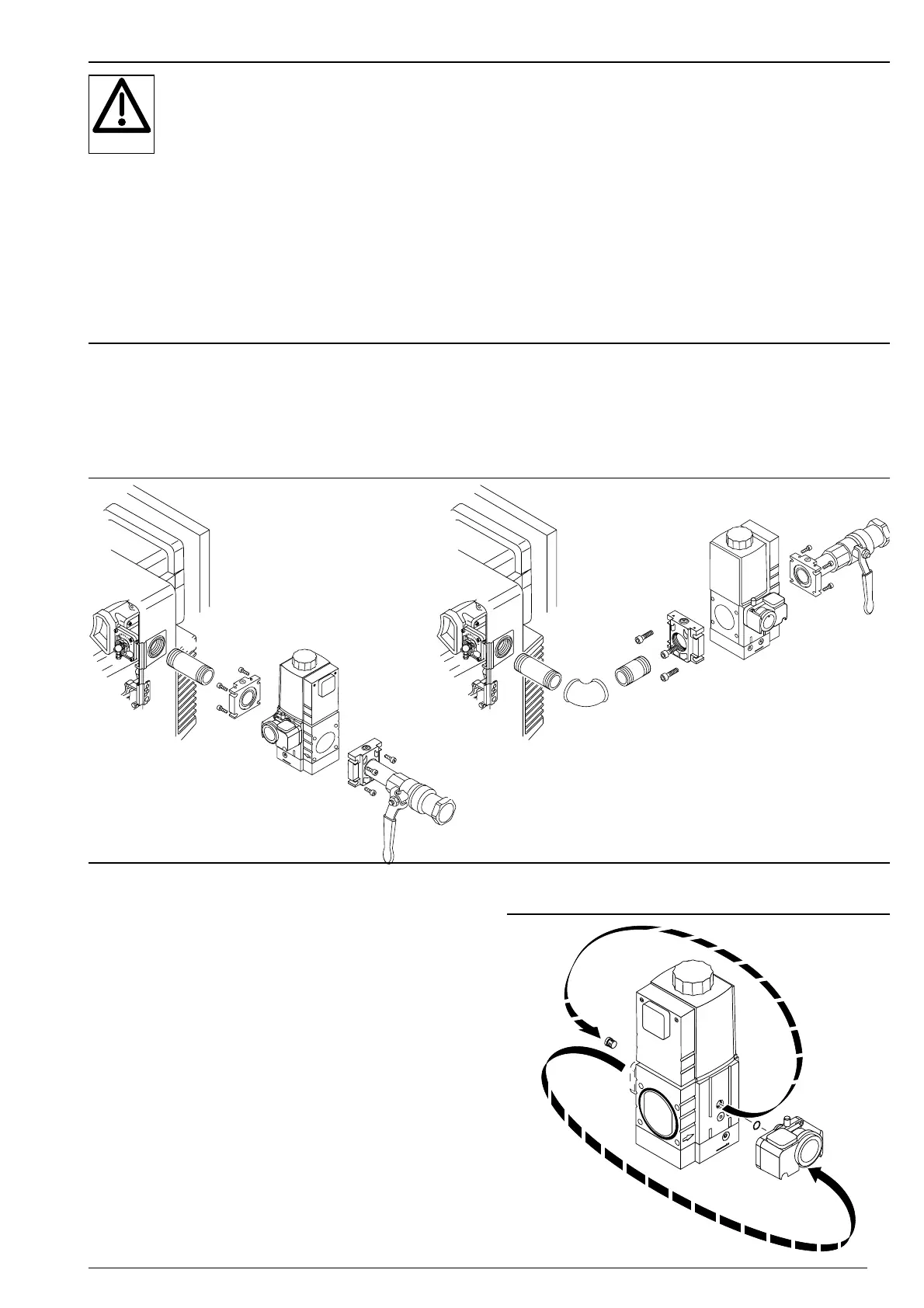

Mounting the valve train from the right

1. Remove the protective film from the gas connection

flange.

2. Mount the components, pre-assembled, in the order

shown in the diagram.

Note W-MF: Can be mounted in horizontal or

vertical pipework.

Installation example

➀ Double nipple

➁ Multifunction assembly W-MF

507

➂ Elbow

➃ Ball valve with flange

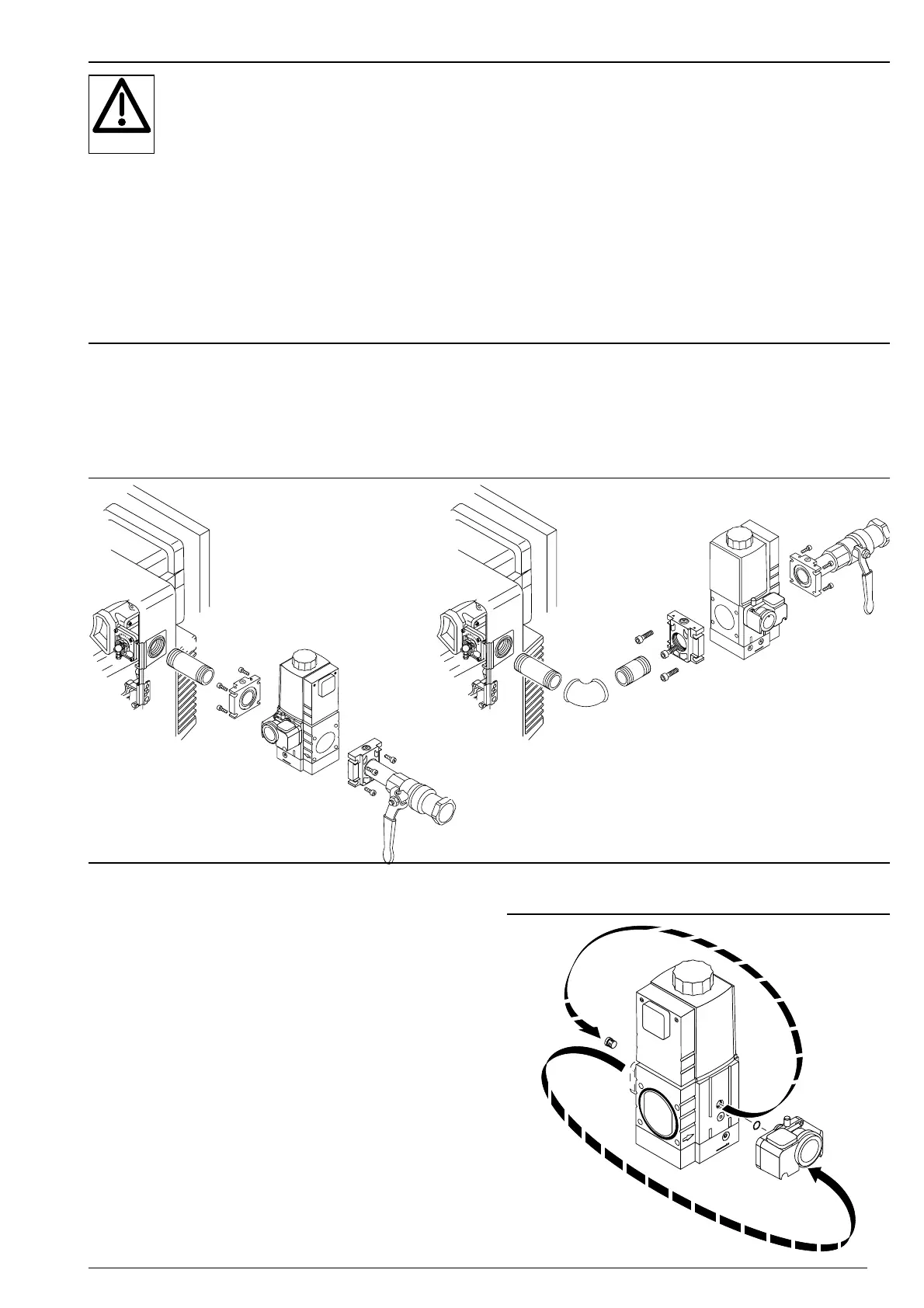

Mounting the valve train from the left

With the burner rotated through 180°, the valve train as

described above can be fitted from the left.

However, the following measures are required.

1. Prior to mounting the multifunction assembly:

Remove gas pressure switch ➂.

2. Remove closing plug ➀.

3. Fit gas pressure switch on opposite side. Pay attention

when fitting the O ring ➁!

4. Refit closing plug on opposite site.

Loading...

Loading...