14

5 Commissioning and operation

5.1 Safety information on initial commissioning

The initial commissioning must only be carried out by the

supplier, manufacturer or their appointed agent. At this

time, all control and safety equipment must be checked to

ensure correct operation and, if they can be adjusted, it

should be checked they have been set correctly.

Furthermore, the correct fusing of the circuits and

measures for protection of electrical equipment and of

associated wiring must be checked.

Note: The burner and gas train combination have not

been factory pre-set.

5.2 Preparations for initial commissioning

Purging the gas supply line

The gas supply line may only be purged by the local gas

authority. Lines have to be purged with gas until the

remaining air or inert gas has been expelled from the line.

The ball valve on the gas train must be kept closed during

supply line pressure tests and purging.

Note If work has been carried out on the gas line,

i.e. exchanging of parts, valve trains or gas

meters, re-commissioning may only be carried

out after the relevant lines have been purged

by the local gas authority.

Check gas supply pressure

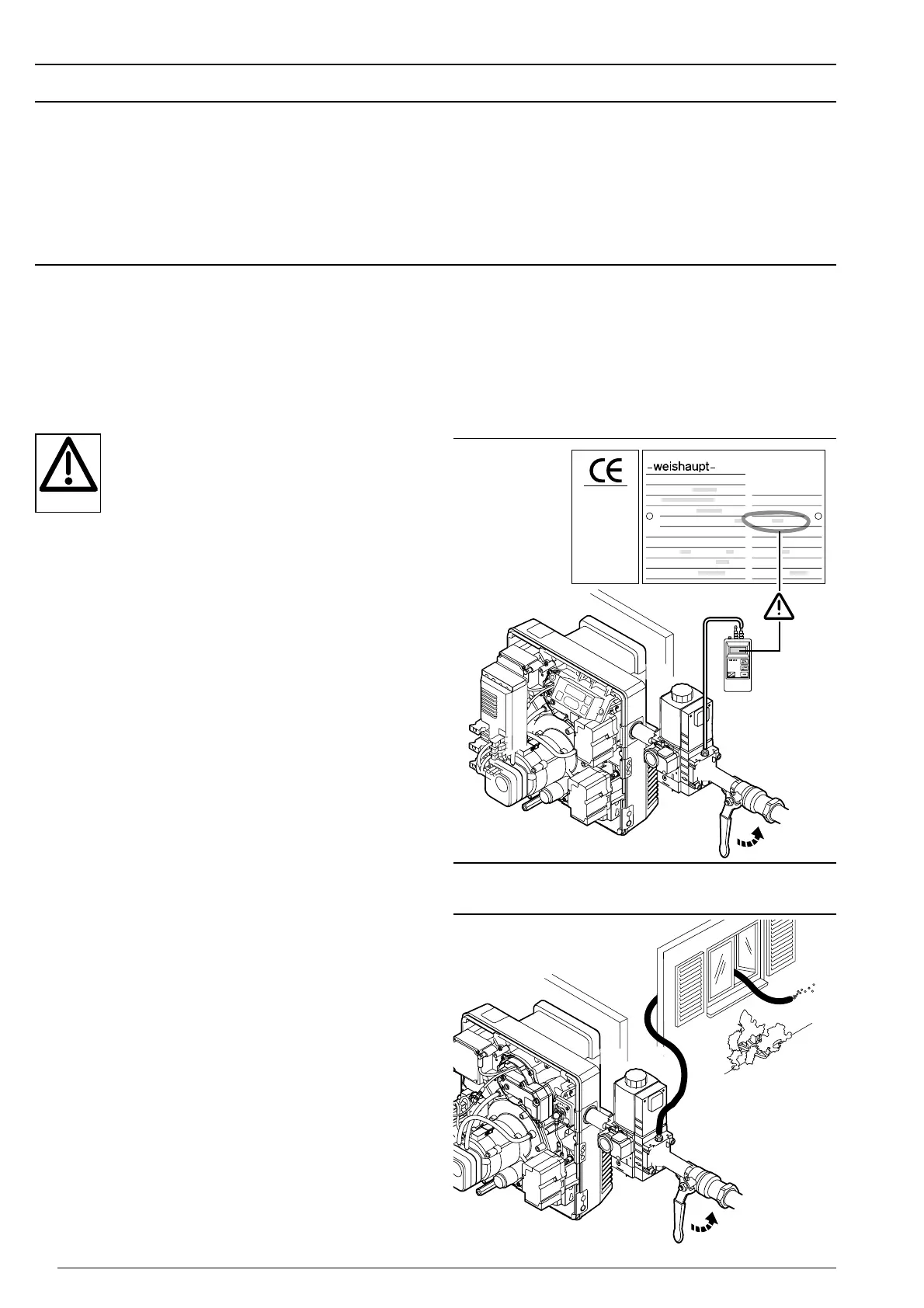

Purging the valve train

Purging the valve train

❏ The gas supply pressure must be correct.

1. Connect a hose, leading out to safe atmosphere, to

test point ➊.

2. Open the ball valve.

The gas in the valve train is vented to safe atmosphere

via the hose.

For smaller gas quantities, a suitable test burner can be

fitted to the outlet of the hose to burn off the gas.

Check gas supply pressure

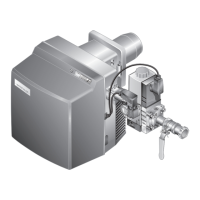

Risk of explosion!

If the supply pressure is too high it can

damage the valve train. The gas supply

pressure must not exceed the maximum

permissible valve train pressure given on the

burner plate. Check the supply pressure

before purging the valve train:

1. Connect manometer to the inlet of the multifunction

assembly (test point ➊)

2. Slowly open the ball valve while watching the

manometer.

3. Close the ball valve immediately if the supply pressure

looks to be going higher than the maximum permissible

valve train pressure (500 mbar).

Do not start burner!

Inform the plant operator.

Loading...

Loading...