7

3 Technical description

3.1 Permissible applications

3.2 Function

The Weishaupt WG10 gas burner is suitable for:

• mounting on heat exchangers according to EN303-3

or DIN4702-1

• on warm water plant with intermittent or continuous

operation (combustion manager will switch off once

during 24h)

Any other use is only permissible with the written

agreement of Max Weishaupt GmbH.

• The burner must only be operated with the type of gas

given on the burner plate.

• The burner must only be operated under the

permissible ambient conditions (see Ch. 8.5)

• The burner must not be used outside. It is only suited

for operation inside.

• The burner must not be used outside of its capacity

range (see capacity graphs, Ch. 8.2).

• The gas supply pressure must not exceed the gas

pressure given on the burner plate.

Burner type

Forced draught gas burner for single-stage or two-stage

operation.

• single stage: ignition load ➱ full load via 4 pole

connection plug (supplied loose, fitted with plug-link

(1) as per wiring diagram).

• two stage: ignition load ➱ partial load ➱ full load via 4

pole plug from heat exchanger.

Combustion manager (W-FM 10)

Main points:

• Safety via internal fuse

• Control and monitoring of all burner functions

• Safety via two microprocessors (reciprocal monitoring)

• Data bus connection (eBUS)

• Signal lamp to show operational status:

Green Burner operating

Flashing green Burner operating with weak

ionisation current

Orange Burner start, internal test

Flashing orange Ignition phase

Red Burner lockout

Flashing orange / red Low voltage or internal safety

fault

Flashing green / red Flame-Simulation

flashing red / orange, Over-voltage

short pause

Flashing red Low gas

Servomotor

A servomotor on the air damper controls the gas/air ratio

via mechanical compound with the gas butterfly valve

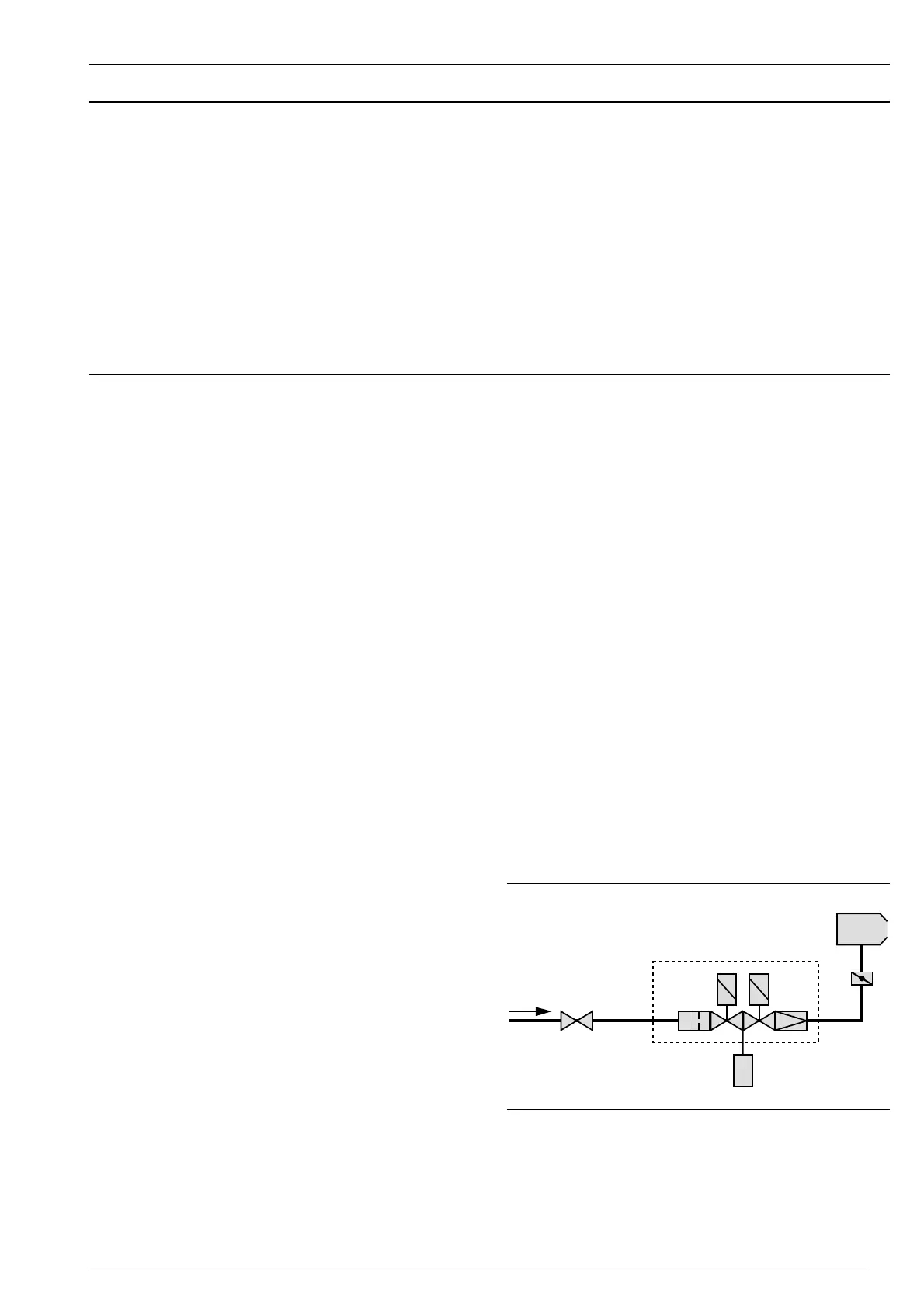

Multifunction assembly W-MF

with the following functions:

• Pressure regulator

Ensures a constant gas pressure to the burner,

negating the affects of gas pressure variations of the

gas supply main. The control pressure is commissioned

with the setting screw.

• 2 Solenoid valves (class A)

• Gas filter

• Gas pressure switch

If the gas pressure is insufficient the low gas

programme is initiated. The gas pressure switch is also

employed for automatic valve proving.

➀ Ball valve with thermal

shut off device

➁ Multifunction assembly

➂ Gas butterfly valve

➃ Burner

Flame sensor

Monitors the flame during all phases of operation. If the

flame signal does not correspond to the sequence of

operations, a safety lockout will occur.

Air pressure switch

If the air supply fails the air pressure switch activates a

safety shutdown.

Sequence of operations

Demand for heat from the appliance controller:

• Servomotor function is tested

• Fan start - prepurge of the combustion chamber

• Ignition on

• Solenoid valves open - fuel release

• Flame formation

• Depending on heat demand the air damper and gas

butterfly open in compound

• After 24 hrs. continuous operation a controlled

shutdown and restart is activated.

Sufficient heat attained:

• Solenoid valves close

• Post-purge of the combustion chamber

• Valve proving of solenoid valves

• Burner switches off to Standby

Schematic of gas valve trains

Loading...

Loading...