CONTROL

PANELS

DESCRIPTION

The generator

mounted

control panelis equipped

with

an

ON switch

(black),

a

START

switch(white) and a STOP

switch (red).

The ON switch provides power to the start circuit.

nus

switch by-passes

the

pr;otective

oil pressure shutdown switch

until the oil pressure reaches

S -

10

psi.

The

START

switch

energizes the start solenoid/starter which

cranks the engine.

1bis switch will not operate unless

the

on

switch is

depressed

and

held at

the

same time.

The STOP switch

will

tum off the engine/generator.

nus

switch must

be

depressed until the stop sequence is complete.

The panel also

has

two

fuses

!O

protect the DC circuit:

•·A

Slow-blo

15Amp

Fuse

to

protect

f;tle

start:

c;ireuit.

•An

8

Amp

Fuse

to

protect

the

engine

operating

circuit

and

any

optitmal

ref!iote.

_paf!elS.

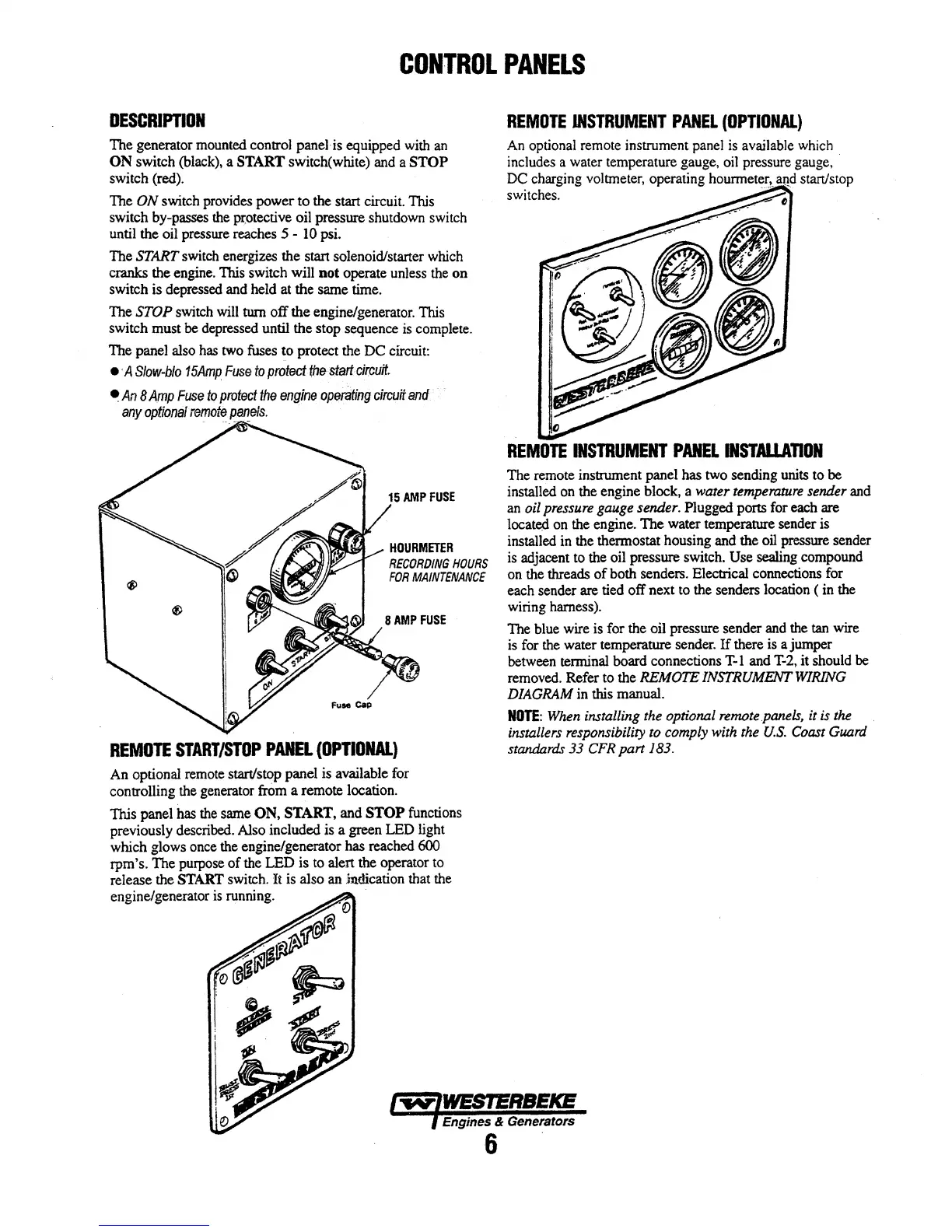

15AMPFUSE

HOURMETER

RECORDING

HOURS

FOR

MAINTENANCE

8AMPFUSE

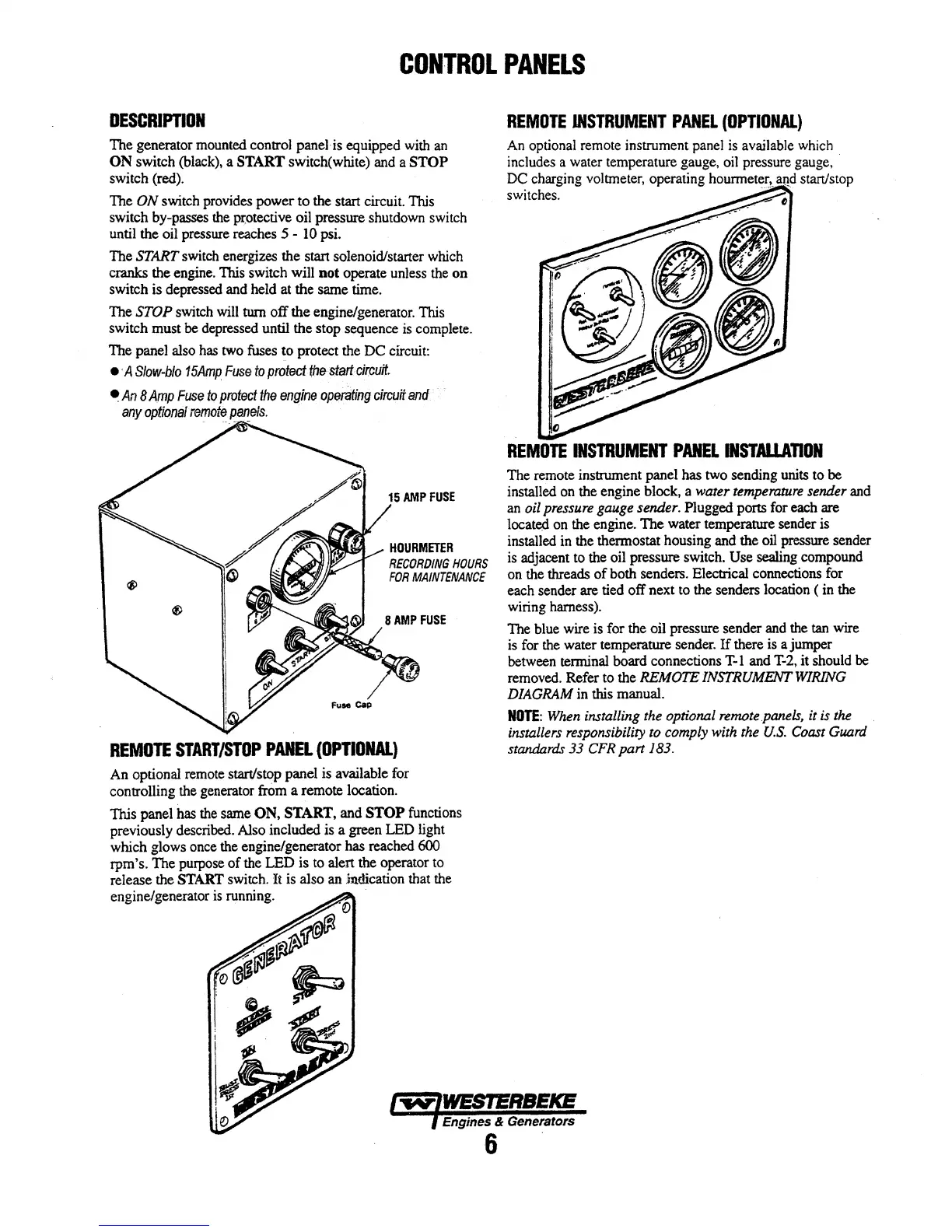

REMOTE

START/STOP

PANEL

(OPTIONAL)

An optional

remote

start/stop panel

is

available

for

controlling

the

generator

frOm

a remote location.

This panel

has

the

same ON, START,

and

STOP functions

previously described. Also included

is

a green

LED

light

which glows

once

the

engine/generator has reached 600

rpm' s. The purpose

of

the

LED is to alert

the

operator

to

release the START switch. It

is

also an indication that

the

engine/generator is running.

()

/

o~

~

,~~

~

REMOTE

INSTRUMENT

PANEL

(OPTIONAL)

An

optional remote instrument

panel

is

available

which

includes a water temperature gauge,

oil

pressure gauge, ·

DC charging voltmeter, operating

hounneter.!.

IU!.d

start/stop

switches.

REMOTE

INSTRUMENT

PANEL

INSTAllATION

The remote instrument panel has

two

sending units to be

installed

on

the engine block, a water

temperature

sender and

an

oil

pressure

gauge

sender. Plugged ports

for

each

are

locate<i

on

the

engine.

The

water temperature sender is

installed in the thermostat housing

and

the

oil

pressure sender

is

adjacent to

the

oil

pressure

switch. Use sealing compound

on

the

threads

of

both senders. Electrical connections for

each sender are tied off next

to

the senders location ( in the

wiring harness).

The blue wire is for the oil pressure sender

and

the tan wire

is

for

the water temperature sender.

If

there

is

a jumper

between

terminal board connections

T-1

and

T-2,

it should

be

removed.

Refer

to

the REMOTE

INSTRUMENT

WIRING

DIAGRAM

in this manual.

NOTE:

When

installing the optional

remote

panels,

it is

the

installers responsibility

to

comply

with

the

U.S.

Coast

Guard

standards

33

CFR

part

183.

Engines & Generators

6 .

Loading...

Loading...